snapetwo

Well-Known Member

OK, so about a year ago i found a 5.7 on craigslist, bought it for $200.

Guy said it ran but had a tick, so his client wanted it replaced.

Had no electronics so no way to fire it.

I took off the heads (wasting the $300 headbolts) and it turns over and looks good from what I see.

Well through the coarse of the year it sat in the garage, uncovered. We had the roof redone and woodchips/sawdust fell all over it.

My question is this. In regards to the "tick" and woodchips. I wouldn't want to try and put it backtogether and have it fail, so I would need to rebuild it. And if I am going thru trouble of tearing it down, rebuilding it, i may as well have it stroked too, maybe bored (read that the walls are to thin for this?).

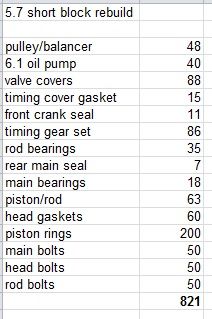

SO my question is, if i tore the engine all the way down, took it to a machine shop and had the machine work done, assuming its not to bad. Then I tried to assemble it (never rebuilt and engine before), using a stroker kit/parts online. What is a good idea of cost? If i have someone rebuild it for me?

VERSUS

buying something online already rebuild and running, maybe already "upgraded", maybe even a 6.1, etc.

Ideas and comments appreciated.

Ultimately I want to be able to drive this on street, take a trip in the mountains, doubt it will see much if any strip time, but id still like it to have some balls to irritate a few folks and melt some rubber. I plan to run a manual tranny and some wide meats in the back if that helps.

Also, i know that the wiring harness and electronics, drive by wire pedal from hotwire auto will cost me about $2000

Guy said it ran but had a tick, so his client wanted it replaced.

Had no electronics so no way to fire it.

I took off the heads (wasting the $300 headbolts) and it turns over and looks good from what I see.

Well through the coarse of the year it sat in the garage, uncovered. We had the roof redone and woodchips/sawdust fell all over it.

My question is this. In regards to the "tick" and woodchips. I wouldn't want to try and put it backtogether and have it fail, so I would need to rebuild it. And if I am going thru trouble of tearing it down, rebuilding it, i may as well have it stroked too, maybe bored (read that the walls are to thin for this?).

SO my question is, if i tore the engine all the way down, took it to a machine shop and had the machine work done, assuming its not to bad. Then I tried to assemble it (never rebuilt and engine before), using a stroker kit/parts online. What is a good idea of cost? If i have someone rebuild it for me?

VERSUS

buying something online already rebuild and running, maybe already "upgraded", maybe even a 6.1, etc.

Ideas and comments appreciated.

Ultimately I want to be able to drive this on street, take a trip in the mountains, doubt it will see much if any strip time, but id still like it to have some balls to irritate a few folks and melt some rubber. I plan to run a manual tranny and some wide meats in the back if that helps.

Also, i know that the wiring harness and electronics, drive by wire pedal from hotwire auto will cost me about $2000