Skeeter007

Skeeter007

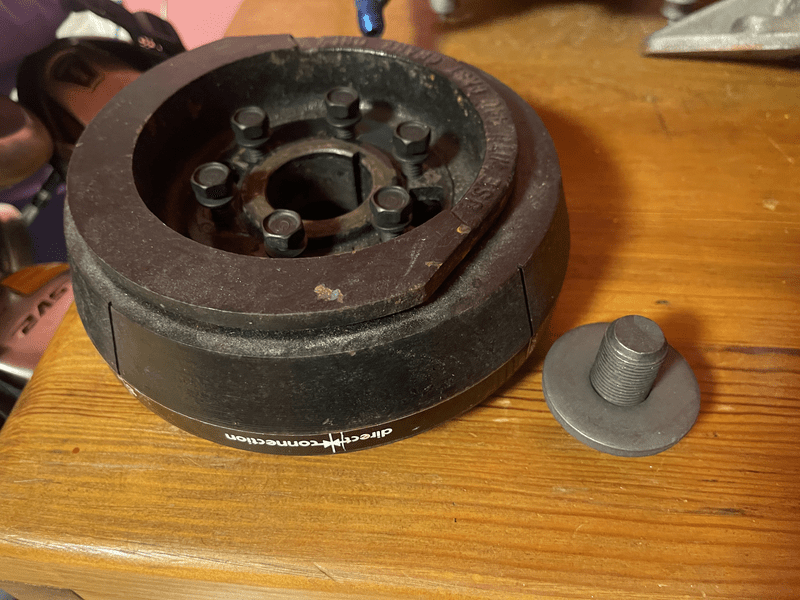

So interesting problem today. I picked up some hardware for the crank and the crank bolt won't fit.

When I try to thread it in it just won't take and gets jammed. This is by hand though. I don't want

to add any torque to it until I consult with you guys. The threads on the bolt seem to be nice and

uniform. The crank threads I can't get a good read on but obviously there is a problem. I'm thinking

I need to chase the threads in the crank shaft. Or do I put a little elbow grease into it with a socket

and ratchet?

Description from the seller.

Reproduction Harmonic Balancer to Crankshaft Bolt and Washer Hardware Package for all 58-79 Big Block Engines only. Made to OEM Specs with “NO” Markings as Per Originals. Made in the USA.

Please see build in signature

When I try to thread it in it just won't take and gets jammed. This is by hand though. I don't want

to add any torque to it until I consult with you guys. The threads on the bolt seem to be nice and

uniform. The crank threads I can't get a good read on but obviously there is a problem. I'm thinking

I need to chase the threads in the crank shaft. Or do I put a little elbow grease into it with a socket

and ratchet?

Description from the seller.

Reproduction Harmonic Balancer to Crankshaft Bolt and Washer Hardware Package for all 58-79 Big Block Engines only. Made to OEM Specs with “NO” Markings as Per Originals. Made in the USA.

Please see build in signature

Last edited: