Disclaimer - I'm not a mechanic but am learning....

Been doing a rebuild/upgrade on the suspension on my 76 Scamp. Did the LCA rebuild with the forged pivot pins from PST. Finally managed to get the torsion bars back in earlier today. Now moved on to the tubular UCA's and am confused.

The set I got is here: 1963-74 Dodge Plymouth Chrysler Mopar A-Body Tubular Upper Control Arm Set The description indicates they are for 63-76, but the part number of TCA-U6374AB makes me question if they are actually only good for 63-74... hmmm... maybe... Also that the title of the webpage link says 63-74, but when you go to the page it says 63-76... so maybe there's something different on the after 74 models and the webpage never got updated?

Anyway, after a bunch of wire brushing, scraping, and using a 12" crescent wrench to try to bend out the mount tabs a bit, I was finally able to get the bolt into the front. Still struggling with the back bolt alignment. My issue is that the UCA hits an edge of the mount tab and stops its downward travel very high.

Here is the drivers side with the UCA pivoted up. Front bolt is in - back bolt still out.

Here is the UCA pivoted down as far as it will go:

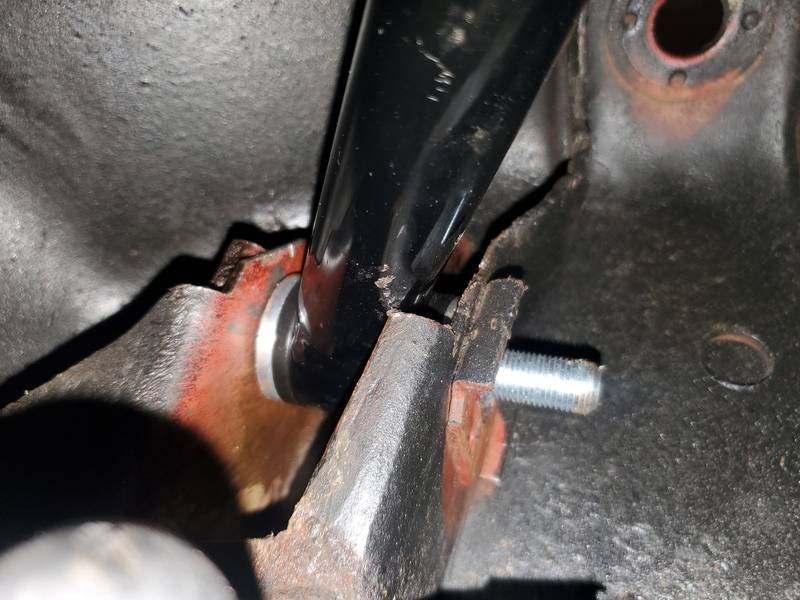

Here is where it is hitting stopping downward travel:

Here's the LCA with the spindle and lower ball joint temporarily bolted in place to try to figure out what my issue is (NOTE - SECONDARY QUESTION - Is the adjustment blade in an ok spot or do I need to try to rotate it up another hex flat 60 degrees higher - I'm not sure I can get it that much higher without hitting the frame rail, so may not even be possible):

Here is the UCA pivoted as low as it will go and the LCA pushed as high as I can get it by hand with the torsion bar adjuster bolt backed out all the way so it's loose.

Obviously the upper ball joint is still several inches too high to be able to connect to the top of the spindle, even with the top pivoted down as far as it will go and the bottom pivoted up as far as it will. The LCA's were rebuilt and are the same ones I took off the car, so it seems they should be usable.

Am I overlooking something obvious with the tubular UCA install? I even thought maybe I was trying to put the wrong one on the wrong side, but holding the other one up looks even more manked up than this one does....

I could likely cut out that tab that is crashing into the UCA and stopping its downward travel, but haven't been able to find a mention of anyone else having to do that...

Ideas??

Been doing a rebuild/upgrade on the suspension on my 76 Scamp. Did the LCA rebuild with the forged pivot pins from PST. Finally managed to get the torsion bars back in earlier today. Now moved on to the tubular UCA's and am confused.

The set I got is here: 1963-74 Dodge Plymouth Chrysler Mopar A-Body Tubular Upper Control Arm Set The description indicates they are for 63-76, but the part number of TCA-U6374AB makes me question if they are actually only good for 63-74... hmmm... maybe... Also that the title of the webpage link says 63-74, but when you go to the page it says 63-76... so maybe there's something different on the after 74 models and the webpage never got updated?

Anyway, after a bunch of wire brushing, scraping, and using a 12" crescent wrench to try to bend out the mount tabs a bit, I was finally able to get the bolt into the front. Still struggling with the back bolt alignment. My issue is that the UCA hits an edge of the mount tab and stops its downward travel very high.

Here is the drivers side with the UCA pivoted up. Front bolt is in - back bolt still out.

Here is the UCA pivoted down as far as it will go:

Here is where it is hitting stopping downward travel:

Here's the LCA with the spindle and lower ball joint temporarily bolted in place to try to figure out what my issue is (NOTE - SECONDARY QUESTION - Is the adjustment blade in an ok spot or do I need to try to rotate it up another hex flat 60 degrees higher - I'm not sure I can get it that much higher without hitting the frame rail, so may not even be possible):

Here is the UCA pivoted as low as it will go and the LCA pushed as high as I can get it by hand with the torsion bar adjuster bolt backed out all the way so it's loose.

Obviously the upper ball joint is still several inches too high to be able to connect to the top of the spindle, even with the top pivoted down as far as it will go and the bottom pivoted up as far as it will. The LCA's were rebuilt and are the same ones I took off the car, so it seems they should be usable.

Am I overlooking something obvious with the tubular UCA install? I even thought maybe I was trying to put the wrong one on the wrong side, but holding the other one up looks even more manked up than this one does....

I could likely cut out that tab that is crashing into the UCA and stopping its downward travel, but haven't been able to find a mention of anyone else having to do that...

Ideas??