If anyone know of one I'm looking for an air condition heater switch to restore the system. Any help gladly appriciated!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1965 Dodge Dart 270 wagon

- Thread starter 65dartcharger

- Start date

-

Your wagon uses the hard-to-find 4 position switch? Interesting as the complete 65 factory AC system I recently bought uses the 5 position switch as does 2 other factory AC set-ups I have had.

IIRC early B Body owners complain the 4 position switch is made of unobtanium. It seems they used the same/similar switch for heat/defrost as well. Their solution was to try and rebuild the switch (vacuum nipples breaking off is the chief complaint).

IIRC early B Body owners complain the 4 position switch is made of unobtanium. It seems they used the same/similar switch for heat/defrost as well. Their solution was to try and rebuild the switch (vacuum nipples breaking off is the chief complaint).

Don! If you mean the buttons it has 5 of them! I've seen different models for 64 - 69 abody. The only difference if the number of wire connections!Your wagon uses the hard-to-find 4 position switch? Interesting as the complete 65 factory AC system I recently bought uses the 5 position switch as does 2 other factory AC set-ups I have had.

IIRC early B Body owners complain the 4 position switch is made of unobtanium. It seems they used the same/similar switch for heat/defrost as well. Their solution was to try and rebuild the switch (vacuum nipples breaking off is the chief complaint).

After 80 hours of hammering dents, sanding and polishing the stainless steel trim they are finally done. Turned out great.

Next thing will be to glass bead lots and lots of stuff to continue the assembling.

Anyone who knows who sell u-challer moulding for a 4 door Dart? Just found windlace moulding!!

Next thing will be to glass bead lots and lots of stuff to continue the assembling.

Anyone who knows who sell u-challer moulding for a 4 door Dart? Just found windlace moulding!!

Finally the front valence is in place. Now the fun starts adding mouldings. Also recieved the halfvmoons for the tail light. That made me mount three of the tail lights. Found out that left inner lens was in wrong package from factory. Inside was a left outside lens w/o back up lights.

Anyone need a lens?

Anyone need a lens?

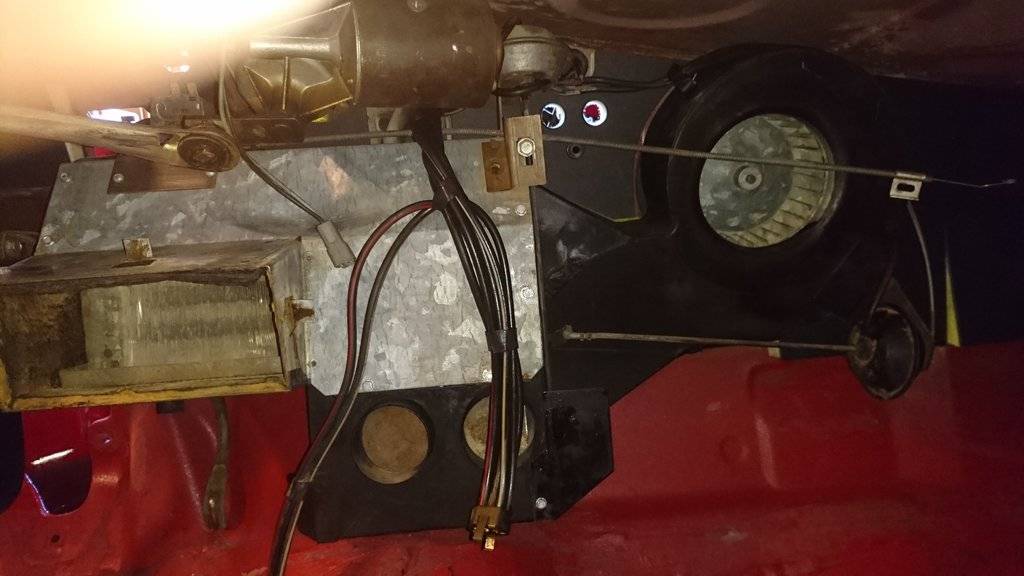

Picked up the radiator and air condition "cooler"(sorry for bad english) and mounted it in place. Next was to mount the last candy cane. Even found a new cap! Love progress!

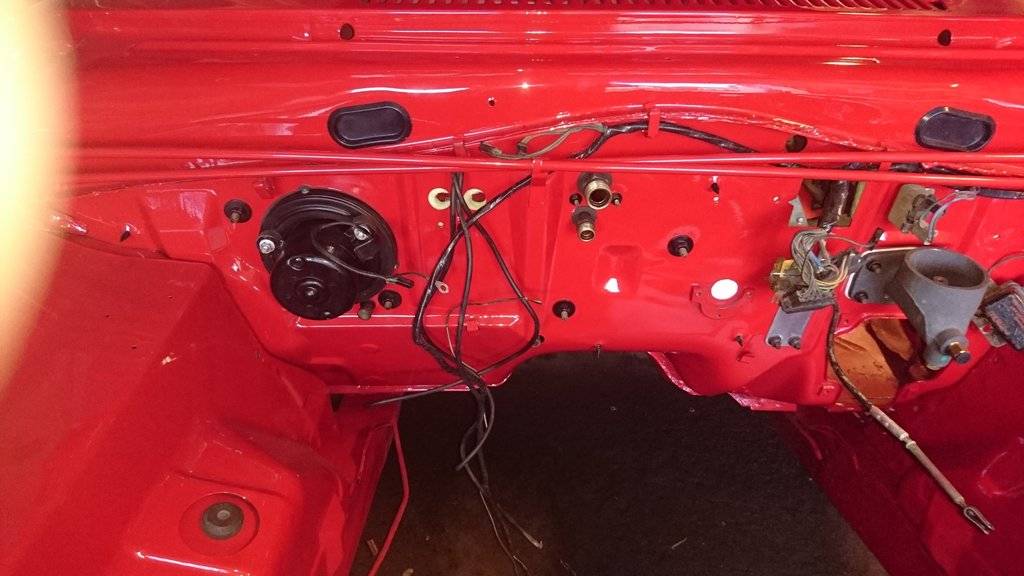

First time out restoring an air condition unit. Wasn't too hard after getting the gaskets and insulation from Jim at Detroit Musclecar Technoligies. Turn out great.

Next is the heater.

Next is the heater.

Heater package done!

Heater package in place, adjusted and all. Next was to add some NOS side mouldings I bought in Sweden yesterday!

Heater package in place, adjusted and all. Next was to add some NOS side mouldings I bought in Sweden yesterday!

View attachment 1715054546

View attachment 1715054547

View attachment 1715054548

View attachment 1715054549

Are you getting all your AC hoses replaced? I will be doing that to run 134. Did you get your drier rebuilt with new desiccant. Classic Air in Florida did mine and you can't ever tell they cut it apart and welded it back together! Having NOS parts like that water valve makes it look so sweet! You are adding NOS moldings - mine to be removed for a nice clean side look!

Thank you! I really enjoy this one and looking forward to have it done.Great job, Ulf. The wagon is looking real nice.

Are you getting all your AC hoses replaced? I will be doing that to run 134. Did you get your drier rebuilt with new desiccant. Classic Air in Florida did mine and you can't ever tell they cut it apart and welded it back together! Having NOS parts like that water valve makes it look so sweet! You are adding NOS moldings - mine to be removed for a nice clean side look!

No, I will stick with the factory one. A friend of mine working to make new refrigirators for Electrolux will help me out with the a/c system.

The water valve is sanded and painted. Sanded the brass and got a nice luster on it. I thought the NOS mouldings will make the car stand out. Then I restore all the other parts. I was even fortune to get the switch on the tailgate to work with factory keys! Will try to build a ignition switch too for the same key.

We appriciate this car so much so I restore the parts to like new condition even if I paint some part to get a close factory finish.

The water valve is sanded and painted. Sanded the brass and got a nice luster on it. I thought the NOS mouldings will make the car stand out. Then I restore all the other parts. I was even fortune to get the switch on the tailgate to work with factory keys! Will try to build a ignition switch too for the same key.

We appriciate this car so much so I restore the parts to like new condition even if I paint some part to get a close factory finish.

Oh! I thought the water valve was NOS - it looked like it in the picture. Everything stands out against that red paint! Hope mine looks as nice considering the paint will be WW1 - plain old white!

White with red interior is my dream combination! But they built my car red on red!!!Oh! I thought the water valve was NOS - it looked like it in the picture. Everything stands out against that red paint! Hope mine looks as nice considering the paint will be WW1 - plain old white!

Today I was able to adjust the sending unit as well as getting new gaskets all around. Now everything is bolted correct. Next is board in the spare tire area and paint all the stuff that goes in there.

White with red interior is my dream combination! But they built my car red on red!!!

My wagon is originally white with blue interior. Of course, the interior will be heavily modified with the 66 Barracuda dash, bucket seats and rear fold down seat - but - still in blue!

I had a blue with blue which I thought was great. Never seen a white with blue. But at Carlisle in time..!My wagon is originally white with blue interior. Of course, the interior will be heavily modified with the 66 Barracuda dash, bucket seats and rear fold down seat - but - still in blue!

How about a blue stripe down the center the same as a GT hardtop? It would break all that white up lol!

I was just looking at the pics of your engine compartment. If your drier is open to the atmosphere at either end, that will not be good. When I sent my drier to Classic Air to be rebuilt with new dessiccant they advised me to not uncap it (at either end) until just before connecting both the line/hoses and the system ws no longer exposed to the moisture in the air. If yours is open, it mill probably need to be rebuilt. Just an observation!

Looking at pics of your engine compartment (again), I noticed that the nuts holding your underdash AC components to the firewall were black phosphate coated. I guess your originals were black. What I find interesting is that on one of my AC setups, the nuts were cad plated and the one I picked up a month or so ago the nuts were black phosphate coated. I had Eric do a set of each just in case I like one better than the other. Since the rest of the fasteners are cad plated, I'm leaning on using the cad plated nuts for the AC

Interesting! Mine were all black phosphated. If you have all of them the same finish I think it would look nicer!Looking at pics of your engine compartment (again), I noticed that the nuts holding your underdash AC components to the firewall were black phosphate coated. I guess your originals were black. What I find interesting is that on one of my AC setups, the nuts were cad plated and the one I picked up a month or so ago the nuts were black phosphate coated. I had Eric do a set of each just in case I like one better than the other. Since the rest of the fasteners are cad plated, I'm leaning on using the cad plated nuts for the AC

Interesting! Mine were all black phosphated. If you have all of them the same finish I think it would look nicer!

The black phosphates nuts stand out against your red paint and would definitely stand out against my white paint. We shall see when the time comes.

Thanks Don! I will plug the other end when I get back home tonight! Try the GT blue stripe on your wagon. It might look as Waggins car! ;-)I was just looking at the pics of your engine compartment. If your drier is open to the atmosphere at either end, that will not be good. When I sent my drier to Classic Air to be rebuilt with new dessiccant they advised me to not uncap it (at either end) until just before connecting both the line/hoses and the system ws no longer exposed to the moisture in the air. If yours is open, it mill probably need to be rebuilt. Just an observation!

Thanks Don! I will plug the other end when I get back home tonight! Try the GT blue stripe on your wagon. It might look as Waggins car! ;-)

If yours has been open to the atmosphere for more than a day or so, the desiccant is likely to be not effective and the drier will need to be rebuilt. I've got another drier currently at Classic Air to be rebuilt.

-