You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

For those interested in building a PTS flowbench...

- Thread starter Cuda416

- Start date

-

Cuda416

Well-Known Member

Here is another diy solution with documentation.

Note, the pages in the PDF files are of order.

Note, the pages in the PDF files are of order.

Last edited:

This could be a good discussion. I know @pittsburghracer has built a couple.Here is another diy solution with documentation.

Note, the pages in the PDF files are of order.

This could be a good discussion. I know @pittsburghracer has built a couple.

The first one I bought was home built by someone else and I loved it but it measured in 10 inches of depression and converted it to 28 inches. Very nice but was limited. I sold it to a friend very cheap. 100% electronics and repeatable. He has learned a lot and loves it.

Cuda416

Well-Known Member

This could be a good discussion. I know @pittsburghracer has built a couple.

I certainly agree. He built the PTS version which I do like. There are plans around from a magazine from the 90s I think that shows how to build another version of the monometer style. I have those somewhere as well.

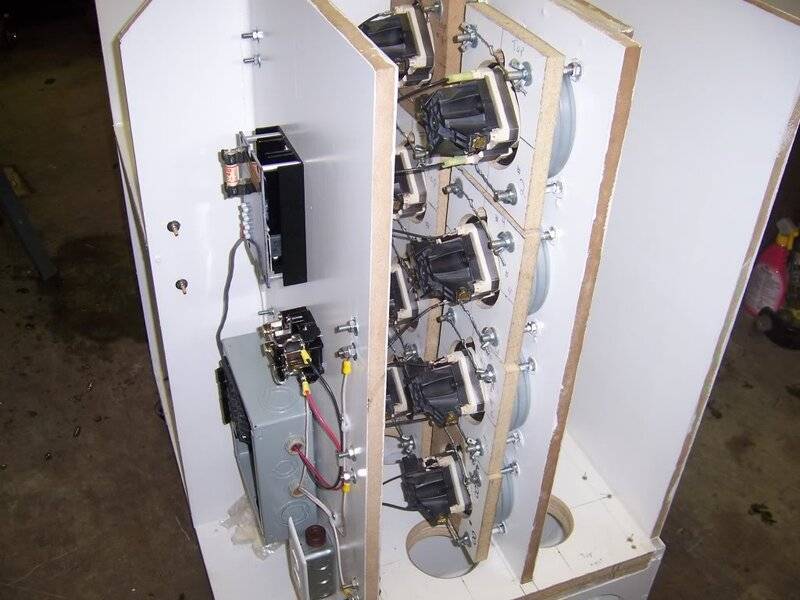

Then I bought a 400cfm commercial bench with two liquid manometers. I hated it. Big blower motor and the liquid manometers were affected by weather hourly. Not repeatable enough for the testing I wanted to do. I went head first reading and learning everything I could about flowbenchs and decided to go with Bruce’s PTS bench. A buddy of mine cut all the wood for me in his shop for a couple cases of beer (he wanted nothing). Built it, wired it, and I know if I’m not over 1000 flow tests I’m close. Heck I’ve done 8 in a single day. To this day I never finished it as it should be final painted and the front doors installed. I can flow a head today and in August I doubt if it would vary 2 cfm because it’s an “orfice” bench not a “pilot” bench. Calibration is checked everytime I change the head mount but it never changes. I have the calibration plates so I check it. It’s an 8 motor bench that can test up to 36 inches and I’ll use that if I have a problem I can’t find. I can test up to a 525-540cfm head. I make my own head mounts out of 1/2 lexan and cylinder sleeves. I then drill them for bench mount holes and use a head gasket to lay out the bolt pattern.

Cuda416

Well-Known Member

That's awesome, thanks for sharing the pics. Looks finished to me. How often do you use all 8 motors? How many are typically used?Then I bought a 400cfm commercial bench with two liquid manometers. I hated it. Big blower motor and the liquid manometers were affected by weather hourly. Not repeatable enough for the testing I wanted to do. I went head first reading and learning everything I could about flowbenchs and decided to go with Bruce’s PTS bench. A buddy of mine cut all the wood for me in his shop for a couple cases of beer (he wanted nothing). Built it, wired it, and I know if I’m not over 1000 flow tests I’m close. Heck I’ve done 8 in a single day. To this day I never finished it as it should be final painted and the front doors installed. I can flow a head today and in August I doubt if it would vary 2 cfm because it’s an “orfice” bench not a “pilot” bench. Calibration is checked everytime I change the head mount but it never changes. I have the calibration plates so I check it. It’s an 8 motor bench that can test up to 36 inches and I’ll use that if I have a problem I can’t find. I can test up to a 525-540cfm head. I make my own head mounts out of 1/2 lexan and cylinder sleeves. I then drill them for bench mount holes and use a head gasket to lay out the bolt pattern.

View attachment 1716061788

View attachment 1716061789

View attachment 1716061790

View attachment 1716061791

View attachment 1716061792

View attachment 1716061793

View attachment 1716061794

View attachment 1716061795

View attachment 1716061796

That's awesome, thanks for sharing the pics. Looks finished to me. How often do you use all 8 motors? How many are typically used?

The first two motors are on a speed control and used to dial in my 28 inches of depression. Around 225 cfm or so I flip on a third motor and that will take me to at least 320 cfm. On my B1 heads that I have up to 420 cfm I ran 4 motors. The only time I’ve had the other on was to exercise them, which reminds me I will do today. Going from intake to exhaust is semi simple. Remove 1/4 inch thick plexiglass directional plate on the right side of the bench, flip over, and reinstall, remove deck plate on left side of the bench and remove four thumb screws, remove sharp edge calibration plate and flip over, install and tighten thumb screws and twist deck cover back on, flip two switches from intake to exhaust, go into your laptop and change the configuration number ( in my case from 600 to 710). I have a second figure for exhaust flowing over 300 cfm. (B1 heads). Those config numbers are arrived at by using your calibration plates. Sad to say but many guys don’t check and or calibrate their benches. If I flow a stock Edelbrock head and it flows 250 and Joe blow checks it and it flows 265 on the finished head my bench would say 310 and his bench would say 325 who are you going to take your heads to??? Many guys will never give you before numbers from THEIR flowbench.

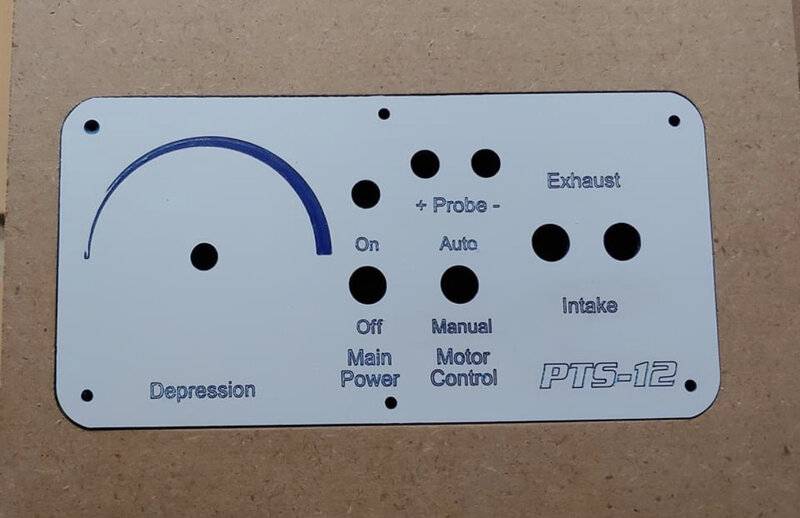

I should add to that on my digital manometer has a place to hook up rubber lines to hook up probes to Check intake (J hook) and exhaust (straight) probes too. Checking airspeed has taught me more than anything and I couldn’t do it till I built this bench. I bought two extra probes as I have a handheld digital manometer and I’m going to see if I can calibrate it so the friend that bought my bench could further his education. I also bought an automatic depression control that when I changed my lift it would automatically go to 28 inches. I bought it probably six years ago and never wired it in. Probably never will. Bruce offered to buy it back from me. Lol. He’s working on a nice panel now and is going to make me one. For the Facebook guys he on there.

Cuda416

Well-Known Member

I should add to that on my digital manometer has a place to hook up rubber lines to hook up probes to Check intake (J hook) and exhaust (straight) probes too. Checking airspeed has taught me more than anything and I couldn’t do it till I built this bench. I bought two extra probes as I have a handheld digital manometer and I’m going to see if I can calibrate it so the friend that bought my bench could further his education. I also bought an automatic depression control that when I changed my lift it would automatically go to 28 inches. I bought it probably six years ago and never wired it in. Probably never will. Bruce offered to buy it back from me. Lol. He’s working on a nice panel now and is going to make me one. For the Facebook guys he on there.

View attachment 1716061803

View attachment 1716061804

Been a bit so I thought I'd bump this up a bit.

What vacuum motors did you use when you built yours? I'm seeing some up on ebay for really cheap that claim new Ametek, single stage, 120,5CFM, 240v at 5.5A. I can get 6 for less then $180.

Is 2 stage important? What other factors need to be considered?

EDIT: Found my plans and the 2 stage 115923 is explicitly called out so single stage is out. That said, these can be found for less than $70 each which isn't bad.

Last edited:

Been a bit so I thought I'd bump this up a bit.

What vacuum motors did you use when you built yours? I'm seeing some up on ebay for really cheap that claim new Ametek, single stage, 120,5CFM, 240v at 5.5A. I can get 6 for less then $180.

Is 2 stage important? What other factors need to be considered?

EDIT: Found my plans and the 2 stage 115923 is explicitly called out so single stage is out. That said, these can be found for less than $70 each which isn't bad.

It’s been so long that I honestly can’t say but in the 50.00 blueprints and instructions Bruce recommended the company and which motors to buy. I recommend joining his website and learning everything you can.

Cuda416

Well-Known Member

It’s been so long that I honestly can’t say but in the 50.00 blueprints and instructions Bruce recommended the company and which motors to buy. I recommend joining his website and learning everything you can.

Yeah I forgot they were listed in the plans but the motors in the link are different now (things change over time). But, as mentioned in my edit above, that just means the older ones are cheaper now.

Yeah I forgot they were listed in the plans but the motors in the link are different now (things change over time). But, as mentioned in my edit above, that just means the older ones are cheaper now.

Mine is way overdue for some maintenance so I would love to remove the motor cover this summer and at least change the brushes in the first four motors and due a little housecleaning. I’ve probably done 1000 flow tests and never had the cover off and when I’m probing a port they are running quite awhile

-