Bill the extension are to equalize fuel bowl pressure. I'm sure your aware that the fuel supply to the carb is a must and it all starts in the fuel bowls if you have a float set to high and a/F ratio might read fat or rich or you may even over flow the vent tubes, and if the floats are set to low chances are you will starve the motor of fuel and read lean a/F ratio.

Now with blow thru carbs sometimes there's inconsistencies in flow in a carb hat so the stock vent tubes don't always see equal pressure by bring them up into the mouth of the hat it keeps that positive pressure on the fuel bowls.

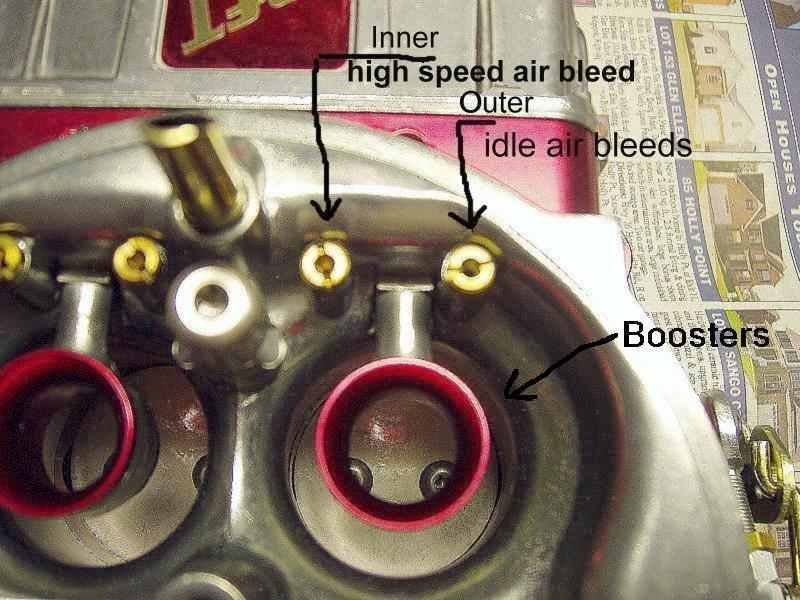

I hope this explanation helps here's a pic

Bill I was also thinking have you and Freddie thought about unhooking the secondaries and trying to tune on the primaries only? Ryan started this way and ran low 11's if you do the math for cfm calculations a slant calls for around 400 cfm that's only Alittle more then half your 750 its just a thought.

Aaron

Aaron,

Thanks for the picture and explanation. Now, I understand, (I think.)

I swapped carbs, putting the blow-thru carb off my 360 on this slant six as an experiment and under full throttle, it was a lot richer than the other (original) carb, showing A/F ratios of 14:1... that was as lean as it got.

I know that the desired A/F ratio under full throttle is more like 11:1, so tomorrow or the next time I get a chance to work on it, some "two steps richer" jets are going into the primaries and the secondaries. I am sure that will help some. If it's not enough to get us into the "good" 11:1 range, I'll increase the jet sizes some more to see if that helps.

General driveability was good (generally, 12:1) with this carb, so we're going to go with it for a few times around the block and see if we can get the A/F ratio where we want it by enlarging the main metering jets.

This carb (this one from the Carb Shop) has a small-diameter steel-braided hose that is plumbed into the top of the float bowl extensions which can only be there to equalize float bowl pressure, I would think. Having that hose already installed, I am wondering... we may not need the vent extensions you described; what do you think?

Oh, btw, this carb does NOT have a BRPV. Just a stock one, with Carb Shop mods.

We might try disconnecting the secondary butterfly linkage just to see how it affects performance. We might need a 600cfm Holley 4-bbl, but, Gerry, up at the G-Pop Shop said that he thinks this engine NEEDS a 750 to generate the 500HP we are looking for. We took all of the turbo mechanisms (blower, waste gate, hat, carb, intercooler, meth injector, etc.) to him for his inspection and advice.

He has a LOT of experience with these things, so when he talks, I tend to listen, but anybody can be wrong...I think he may have had a lot to do with Ryan's engine build; not sure.

Today we made 8 pounds of boost out on the hiway, after filling the fuel cell up with some 110-octane VP fuel, ($10.00/gal.!) and putting pure meth in the Boost Cooler. I am not sure, but our waste gate may be set on 8 psi, and that may be the reason the boost didn't climb higher. It got up to 8 in a hurry...

That waste gate adjustment will be the next thing we check, after the carb re-jetting. We don't have the mechanical boost controller installed into the system, yet, but we will...

FYI, this car will see VERY LITTLE street driving, with the great bulk of its miles coming on the drag strip, so "driveability" and gas mileage are not important to us; output IS.

Thanks for all your help and advice; we're gettin' there.... that 8 pounds of boost felt pretty good on the seat on the pants... :blob:

:wack:

Lookin' for 20...