You r doing a great job. Looks good so far. AMD quarters can b a pain. I had problems with my 72 demon 1/4 as well. There was an inch too much meat on the bottom front and I had to cut it in half and weld it back together to get it in. Also had to add a pie in the top to fit the door. They look good once on and reworked. You ll get it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Canadian H-Code 340 Dart Swinger Special Resto - Finally started!

- Thread starter Swinger340Canuc

- Start date

-

Swinger340Canuc

72 Swinger 340 Special

Looking good Danny! I agree, it was pretty warm this weekend.. Kinda kills the motivation sweating like crazy in the garage. That sucks about the quarter being so short on the drivers side and the wheel well tub giving you troubles. Mine was good on the drivers side, but my passenger side one was really short, which is why I welded the 1/8" welding rod down my door edge to get the gap back. I wonder why there's so much variance between stampings?

Looks like your method is the best one to fix this problem Randy, I should have some 1/8 tig rod. I should unpack the right quarter and measure it, it's probably perfect and if we had traded panels neither of us would have to do all this work, lol!

Thanks. I will, but I don't expect to have them finished any time soon.

If you need some better pictures let me know, I also posted better pics in the Shop, Garage and Tools forum in the wanting ideas on building a body cart for 70-74 a bodies thread.

http://www.forabodiesonly.com/mopar/showthread.php?t=277475

inspiring lol you work fast

Could be faster wade, busy as hell at work and lots of visiting on weekends, these seven day weeks aren't cutting it need more days,lol.

Swinger340Canuc

72 Swinger 340 Special

You r doing a great job. Looks good so far. AMD quarters can b a pain. I had problems with my 72 demon 1/4 as well. There was an inch too much meat on the bottom front and I had to cut it in half and weld it back together to get it in. Also had to add a pie in the top to fit the door. They look good once on and reworked. You ll get it.

Thanks evil 340, I'm starting to get my head around the issues and how I need to proceed. Hoping the right sides a bit better fit.

If you need some better pictures let me know, I also posted better pics in the Shop, Garage and Tools forum in the wanting ideas on building a body cart for 70-74 a bodies thread.

Thanks again! I agree with jdakota, very nice work, in deed!

Swinger340Canuc

72 Swinger 340 Special

I haven't managed to work on the car much the last two weeks but got a bit of sandblasting done the other evening on the areas that have some surface rust and the weld areas.

Cleaned up and needs some epoxy then I can set the tub back in place and trunk floor drop and hopefully get those two welded in this weekend. I want to clean the inside of the rocker out while its open on the end and spray some Eastwood encapsulated sealer inside as well.

View attachment 1715161788

I also decided to remove the factory wire harness straps from my old trunk drop and put them on the AMD one since theirs were quite a bit shorter then the originals and the only had two instead the three that the factory had.

Epoxied the drop and tub while they were off so their ready for putting back in place and a final test fit then weld them in place.

Hopefully I can get a bit a accomplished this weekend.

View attachment 1715161778

View attachment 1715161781

Cleaned up and needs some epoxy then I can set the tub back in place and trunk floor drop and hopefully get those two welded in this weekend. I want to clean the inside of the rocker out while its open on the end and spray some Eastwood encapsulated sealer inside as well.

View attachment 1715161788

I also decided to remove the factory wire harness straps from my old trunk drop and put them on the AMD one since theirs were quite a bit shorter then the originals and the only had two instead the three that the factory had.

Epoxied the drop and tub while they were off so their ready for putting back in place and a final test fit then weld them in place.

Hopefully I can get a bit a accomplished this weekend.

View attachment 1715161778

View attachment 1715161781

Last edited:

Swinger340Canuc

72 Swinger 340 Special

Back at it yesterday and today, got some done, never as much as I'd like but I decided I had to do some more sandblasting and get at some areas that are a lot easier with it open like it is. Then weld up a few holes and other spots that need fixing

Reamed out my rocker panel while it open with my dryer vent brush so any loose stuff could blow out then coated the inside with Eastwood's internal frame coating.

Then it was time for some epoxy to seal it all up.

You can see the problem with that I had with the front of the tub in the next two pictures. The tub was curved away from the rocker and left a large gap and it also stuck out from the rocker not allowing the quarter panel seat in at the bottom the way it needs to.

These two cuts, the upper one hinges at the crest of the outer lip and allows the tub to move inward and the lower one allows the tub to move towards the rocker panel and ended up with a nice tight fit inward and against the rocker.

Then fit the tub and tunk drop back on and hang the quarter AGAIN and check the fit then mark the tub and flanges for the welding spots and clean these to bare steel and prime fit the tub for the last time,

Then weld her in, the five on the inside of the sail panel are a bit more fun since you have to do them at arms reach so they're not my best welds but nobody will ever see them.

Maybe if I have some jam left after work tomorrow I'll weld the trunk drop in, most of those welds I'd like to do with my spot welder where ever possible. Then a bit more epoxy and paint inside before moving on to the quarter which will need a bit of modifying on the bottom at the rocker for a snug fit.

Reamed out my rocker panel while it open with my dryer vent brush so any loose stuff could blow out then coated the inside with Eastwood's internal frame coating.

Then it was time for some epoxy to seal it all up.

You can see the problem with that I had with the front of the tub in the next two pictures. The tub was curved away from the rocker and left a large gap and it also stuck out from the rocker not allowing the quarter panel seat in at the bottom the way it needs to.

These two cuts, the upper one hinges at the crest of the outer lip and allows the tub to move inward and the lower one allows the tub to move towards the rocker panel and ended up with a nice tight fit inward and against the rocker.

Then fit the tub and tunk drop back on and hang the quarter AGAIN and check the fit then mark the tub and flanges for the welding spots and clean these to bare steel and prime fit the tub for the last time,

Then weld her in, the five on the inside of the sail panel are a bit more fun since you have to do them at arms reach so they're not my best welds but nobody will ever see them.

Maybe if I have some jam left after work tomorrow I'll weld the trunk drop in, most of those welds I'd like to do with my spot welder where ever possible. Then a bit more epoxy and paint inside before moving on to the quarter which will need a bit of modifying on the bottom at the rocker for a snug fit.

Last edited:

Swinger340Canuc

72 Swinger 340 Special

Back at it some today, as usual didn't accomplish as much as I'd like but did get the trunk drop welded in and tried for the first time using Fusor's weld thru seam sealer which should make these flanges water tight and never be a problem. Used the spot welder this time which worked out nicely to give a factory look and welded thru the seam sealer no problem thou a bit messy since some of it drips out from the heat but worth it where you can us it which is only with the induction type spot welder, mig is really too hot and tends to burn it up.

Last edited:

" Fusor's weld thru seam sealer which should make these flanges water tight and never be a problem. "

Where did you find this stuff???

Where did you find this stuff???

Spot welder does a nice job. Coming together very nicely.

Swinger340Canuc

72 Swinger 340 Special

" Fusor's weld thru seam sealer which should make these flanges water tight and never be a problem. "

Where did you find this stuff???

You can get at bodyshop supply houses or the easiest would be on Amazon BB-Dave. The American Amazon seams to carry the full line of bonding adhesives and seam sealers, pretty much the whole line of products. You can go on fusor's website and get some instructions on uses and how to.

Swinger340Canuc

72 Swinger 340 Special

Spot welder does a nice job. Coming together very nicely.

Thanks Kev, yeh it works pretty well if you put the time in to prep the surfaces properly. It doesn't accept taking short cuts to well.

The car only got some of my attention today, the hairy kids needed some trimming up so that took up the best part of the morning and we were all glad when it was done!!!

Last edited:

Swinger340Canuc

72 Swinger 340 Special

Back at it this afternoon, tidy up some welds a bit of sanding and seam seal some joints. Then mask and Epoxy her again and base then some clear. Now I can turn my attention to the final fit of the quarter which will need a couple of mods on the lower front, pretty simple stuff but needed so the body lines will match up its easier to mod the bottom.

Last edited:

Hemiorangeswinger

Dodge Material

That looks really good Danny! Hemi Orange is such a nice colour... Our cars will look good side by side at a car show!

That's a cute dog.

That's a cute dog.

Swinger340Canuc

72 Swinger 340 Special

That looks really good Danny! Hemi Orange is such a nice colour... Our cars will look good side by side at a car show!

That's a cute dog.

Your right Randy, I'm looking forward to the day, I'm pretty sure your going to be enjoying yours before me but you've been working a lot harder on yours then I have on mine so that's the way it should be. The pups are sister and little brother and the hair grows like mad!

Swinger340Canuc

72 Swinger 340 Special

Back at it this weekend, first task is to dig out my template and drill the holes on quarter for the DART emblem.

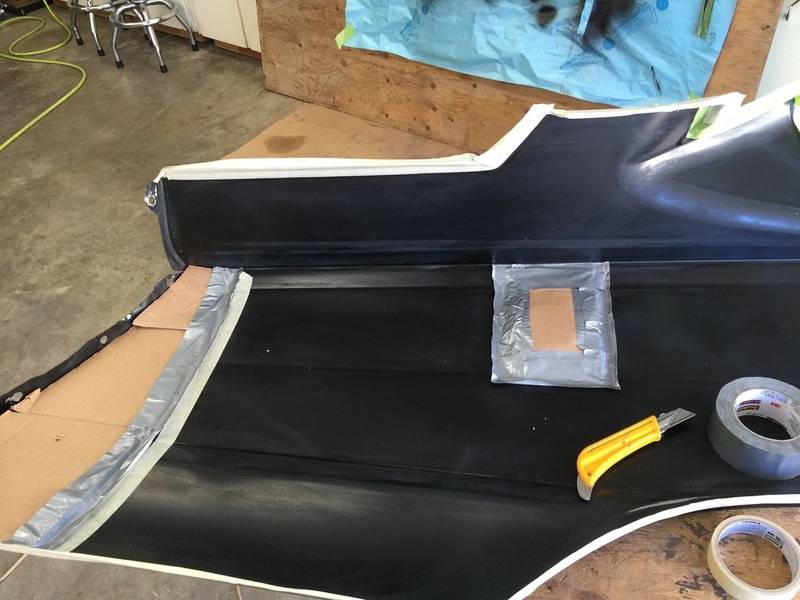

Then the it was time to address the main problem with my AMD quarter panel. A bit dis-appointing that its both short in length and short on the bottom, they are such a nice straight part so this is extra work I wish I didn't have to deal with but this was the way I addressed it.

I got all the body lines to line up and they are pretty good at the trunk also,

I end up with these gaps at the bottom which left me with no choice but to section the panel too lengthen it so it will properly wrap around the rocker and meet up with the rocker panel.

This is the point at which it needs to be cut, unfortunately ones going to get some warpage welding it back together and will need some metal massaging later.

Now that I've got it lengthen'd I'll hang the quarter back on the car and clamp the lower section over the new metal into the position where everything meets up properly and run a tape line where the new cut will need to be.

Fits pretty nice now so time to weld her back up then it need some work to deal with the warpage but now it fits.

Then the it was time to address the main problem with my AMD quarter panel. A bit dis-appointing that its both short in length and short on the bottom, they are such a nice straight part so this is extra work I wish I didn't have to deal with but this was the way I addressed it.

I got all the body lines to line up and they are pretty good at the trunk also,

I end up with these gaps at the bottom which left me with no choice but to section the panel too lengthen it so it will properly wrap around the rocker and meet up with the rocker panel.

This is the point at which it needs to be cut, unfortunately ones going to get some warpage welding it back together and will need some metal massaging later.

Now that I've got it lengthen'd I'll hang the quarter back on the car and clamp the lower section over the new metal into the position where everything meets up properly and run a tape line where the new cut will need to be.

Fits pretty nice now so time to weld her back up then it need some work to deal with the warpage but now it fits.

Last edited:

daredevil

Well-Known Member

Thanks for the fine documentation of your progress. Having just picked up a rusty numbers matching 69 340 dart these pics will prove invaluable to me later.

Swinger340Canuc

72 Swinger 340 Special

Thanks for the fine documentation of your progress. Having just picked up a rusty numbers matching 69 340 dart these pics will prove invaluable to me later.

Hope it helps anyone else that runs into similar problems, I'm always picking up tips from other members posting that have helped me.

Hemiorangeswinger

Dodge Material

That looks really good Danny! I think the reason I never had that problem is I replaced the rockers and moved them up a bit to close the gap up on the rocker to door gap. Mine had a HUGE 1/2" door to rocker gap from factory and I put the new rocker on with about a 3/16" gap which probably gave me the extra room needed..

I still wanna come by and check your car out, but my car keeps taking all my free time, haha.

I still wanna come by and check your car out, but my car keeps taking all my free time, haha.

Swinger340Canuc

72 Swinger 340 Special

That looks really good Danny! I think the reason I never had that problem is I replaced the rockers and moved them up a bit to close the gap up on the rocker to door gap. Mine had a HUGE 1/2" door to rocker gap from factory and I put the new rocker on with about a 3/16" gap which probably gave me the extra room needed..

I still wanna come by and check your car out, but my car keeps taking all my free time, haha.

Evening Randy, that could be the difference, mine has a large door to rocker gap. I've been meaning to bring your template back and make a template of that small bumper on your hump but everything takes me longer then I plan. Come out any time it works for you!

Hemiorangeswinger

Dodge Material

Evening Randy, that could be the difference, mine has a large door to rocker gap. I've been meaning to bring your template back and make a template of that small bumper on your hump but everything takes me longer then I plan. Come out any time it works for you!

I bet that's why they come up short lengthways.. They didn't take into fact the rockers are welded on lower on most cars. Yeah you're welcome to come by anytime and make up a template of the seat stopper. I will be around this weekend. I should have the bottom of my car all done by then as well. If you're around this weekend I'll plan to come by! I know the feeling on everything taking longer than expected! Haha

Swinger340Canuc

72 Swinger 340 Special

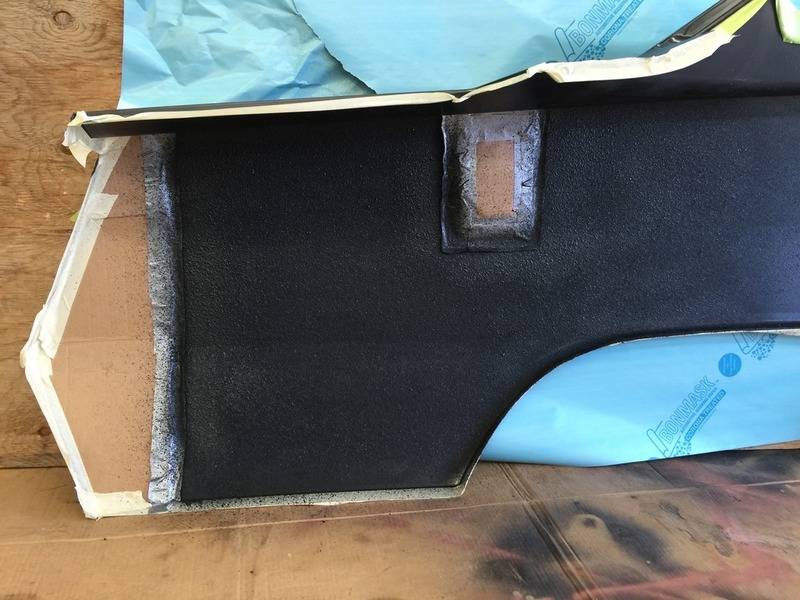

Try and get back at this quarter a bit, other stuff eating into my time for the car. Prep the inside of the quarter starting with a skim of AllMetal over my butt weld and try to match up the undercoating on the inside.

Thanks Hemiorangeswinger for putting me on to RestoRick's matching undercoating, really easy to work with and builds nicely to an excellent in depth and texture, happy with the way it looks!

Some Epoxy and some Hemiorange and clear.

Next should be prep all the edges and surfaces for welding.

View attachment 1715293893

Thanks Hemiorangeswinger for putting me on to RestoRick's matching undercoating, really easy to work with and builds nicely to an excellent in depth and texture, happy with the way it looks!

Some Epoxy and some Hemiorange and clear.

Next should be prep all the edges and surfaces for welding.

View attachment 1715293893

Last edited:

Hemiorangeswinger

Dodge Material

That looks awesome Danny! Thanks for showing me the car this weekend, it's coming along great!

Swinger340Canuc

72 Swinger 340 Special

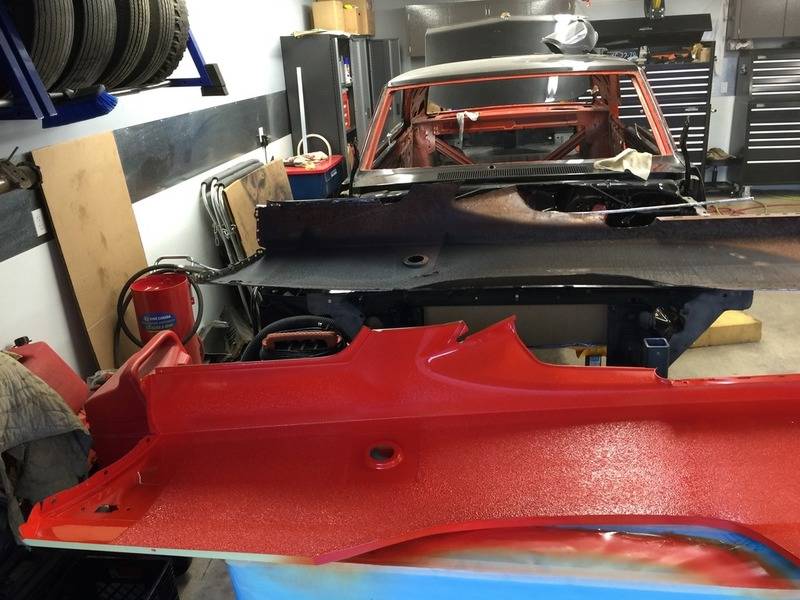

Hung the quarter on hopefully the last time to layout where the plug welds will go and drill for those and mark where I want the spot welds to land. A lot of prep needed since I'm going to use some Fusor panel bonding at the rear cowl and corner of the window as well as the weld thru seam sealer on the areas I can use the induction spot welder. Once you lay the panel on this stuff you don't want to have to move it or you'll have a bit of a mess to wipe off.

I happy how the inside turned out and should look like factory except a little shinier.

Picked up my parts from the dipper today turned out overall not bad but I think Hemiorangeswinger's turned out a bit better then mine, Randy what's up LOL!

Unfortunately they dropped my hood on a bad spot at the back, now any spot is a bad spot on a hood, looks like it slipped out of someones hands lifting it and it landed on the edge of the tank. I put the hammer and dolly to it and it came out pretty nicely in about 15 mins so it turned out to be not a big deal.

Spent some time sanding the hood down, lost some hood brace adhesive globs and some have come loose so I need to replace those before I do anymore on the hood.

I happy how the inside turned out and should look like factory except a little shinier.

Picked up my parts from the dipper today turned out overall not bad but I think Hemiorangeswinger's turned out a bit better then mine, Randy what's up LOL!

Unfortunately they dropped my hood on a bad spot at the back, now any spot is a bad spot on a hood, looks like it slipped out of someones hands lifting it and it landed on the edge of the tank. I put the hammer and dolly to it and it came out pretty nicely in about 15 mins so it turned out to be not a big deal.

Spent some time sanding the hood down, lost some hood brace adhesive globs and some have come loose so I need to replace those before I do anymore on the hood.

Last edited:

Hemiorangeswinger

Dodge Material

The quarter looks great! You're on the homestretch now.. Just think, you get to do it all over again!

That sucks they dented your hood... Sounds like terrible luck! Did they at least take responsibility for it? I feel almost responsible for the bad luck you had since I recommended them to you. That's weird the seam sealer failed! Maybe they had to soak yours longer to get the extra paint/bodywork off?

That sucks they dented your hood... Sounds like terrible luck! Did they at least take responsibility for it? I feel almost responsible for the bad luck you had since I recommended them to you. That's weird the seam sealer failed! Maybe they had to soak yours longer to get the extra paint/bodywork off?

Johnny Dart

Well-Known Member

Subscribed.......:burnout::glasses7:

-