You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedmaster Small block porting tips and results Part 1

- Thread starter pittsburghracer

- Start date

-

PRH

Well-Known Member

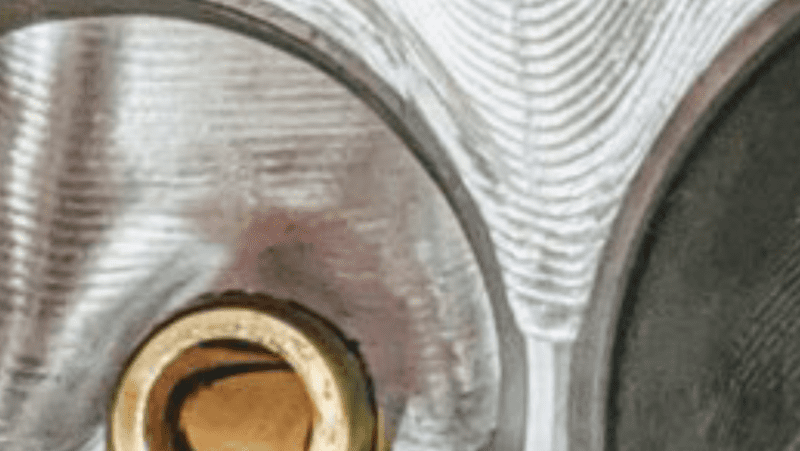

PBM rocker(same as SM rocker) vs Crane rocker.

The Crane rocker has plenty of room.

The Crane rocker has plenty of room.

Last edited:

PRH

Well-Known Member

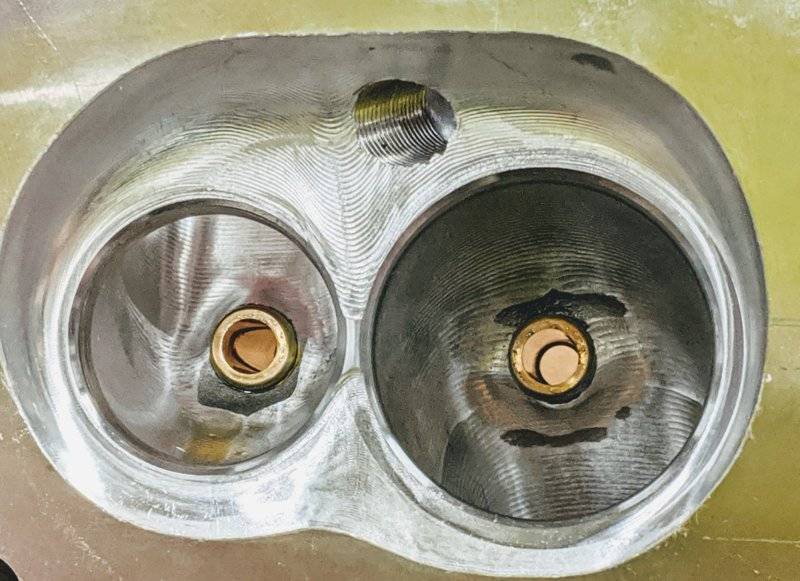

Looks like they cnc’d some of the 45 away on those seats.

Imo, that cnc’d chamber version really needs a bigger intake valve, a valve job, and some blending around the seats.

Nothing about the way the seats are done on that head does anything good for the flow.

My advice....... buy ‘em bare and have them “done”.

If that puts you too close to TF money...... then buy the TF’s.

Imo, that cnc’d chamber version really needs a bigger intake valve, a valve job, and some blending around the seats.

Nothing about the way the seats are done on that head does anything good for the flow.

My advice....... buy ‘em bare and have them “done”.

If that puts you too close to TF money...... then buy the TF’s.

Last edited:

gzig5

Well-Known Member

For those interested in the SM-SS rockers , SM rockers hit the retainers on SM heads

View attachment 1715447617

That's pretty much what my PRW 1.6 look like on the ProMaxx head. Probably because the rockers came out of the same mold and machining center. It won't take much blending on the rocker body to get clearance to the spring retainer, but like you show, they need to move back and maybe up a bit to better center on the stem. I almost prefer it this way. I'm having to pay attention and learning a lot more than if all these parts just bolted together and fit perfectly. What's the fun in that, right?

@dogbreath

Did you order your heads assembled? Best I was able to find is that the ones with the CNC'd camber are only available bare.

Did you order your heads assembled? Best I was able to find is that the ones with the CNC'd camber are only available bare.

I will have to look. I put the steel rockers on my heads and noticed some interference with the spring/retainer. I also noticed the roller not perfectly centered on the stem. With some shims and a B3 kit I bet there will be needed clearance. Depending on what cam I use I might not need the double springs. Could always go with beehive's.

Last edited:

Are you using the tapered shims ? Studs ? Be sure not to over torque the shafts on the stands.

PRH

Well-Known Member

I wonder if the intructions that come with the rockers tell you that the rockers won’t fit without additional parts....... or modifications.

aaronk785

Well-Known Member

Any idea how much flow I'll lose not doing the chamber work. Trying to keep comp. up. How many cc.s will I lose doing the chamber.

A little grinding on the on the arm doesn't hurt to gain a little clearance.

Just finger tight to test.Are you using the tapered shims ? Studs ? Be sure not to over torque the shafts on the stands.

I don't think there are any instructions. I will have to look.I wonder if the intructions that come with the rockers tell you that the rockers won’t fit without additional parts....... or modifications.

They say 3cc difference. Yes the CNC Speedmasters did come assembled. Kim

I did that to my 273 rockers.A little grinding on the on the arm doesn't hurt to gain a little clearance.

Hopefully you can get the sweep more centered on the stem, but it's not looking good.alignment at +.030 , have not done a full sweep yet , can´t find my checking springs. I´d like to check the full sweep with some .040 hughes shims under the shafts.

View attachment 1715447620

gzig5

Well-Known Member

I wonder if the intructions that come with the rockers tell you that the rockers won’t fit without additional parts....... or modifications.

You know as well as anyone, there is fit and then there is fit. The rockers probably fit fine with stock diameter springs. They will surely make the valve go up and down. Obviously not optimized but that is part of the joy of buying bottom dollar parts. The fact that their own brand labeled rockers align so poorly on their own heads should be embarrassing for them. Product Marketing people have no soul, they sell whatever you put in front of them. It's a shame they don't do the little bit of design changes required to make everything line up like it should but they are probably too busy making and selling Ford and Chevy parts by the shipload, rather than a few containers of Mopar parts. The date codes on some of these heads is telling. They obviously haven't been flying off the shelves and requiring multiple casting runs each year to resupply.

yellow rose

Overnight Sensation

alignment at +.030 , have not done a full sweep yet , can´t find my checking springs. I´d like to check the full sweep with some .040 hughes shims under the shafts.

View attachment 1715447620

They hit because the rocker geometry is WRONG. It will be wrong with damn near any rocker you use.

The Hughes shims are JUNK. They are, at best, a half assed fix and they can break the saddle.

The best fix is found at b3racingengines.com.

Go read all his tech pages and then call him and get the RIGHT correction kit for YOUR application.

Anything else is not correct.

yellow rose

Overnight Sensation

You know as well as anyone, there is fit and then there is fit. The rockers probably fit fine with stock diameter springs. They will surely make the valve go up and down. Obviously not optimized but that is part of the joy of buying bottom dollar parts. The fact that their own brand labeled rockers align so poorly on their own heads should be embarrassing for them. Product Marketing people have no soul, they sell whatever you put in front of them. It's a shame they don't do the little bit of design changes required to make everything line up like it should but they are probably too busy making and selling Ford and Chevy parts by the shipload, rather than a few containers of Mopar parts. The date codes on some of these heads is telling. They obviously haven't been flying off the shelves and requiring multiple casting runs each year to resupply.

It's not the diameter of the spring. The geometry is wrong and if you fix that, the interference goes away.

skrews

Well-Known Member

Personally not seeing anything that WOWs me in the CNC chamber.

gzig5

Well-Known Member

A little grinding on the on the arm doesn't hurt to gain a little clearance.

I agree. But, I'm going to do something to get better alignment to the valve so that should move the rocker such that material won't need to be removed. So I may just leave them be.

-