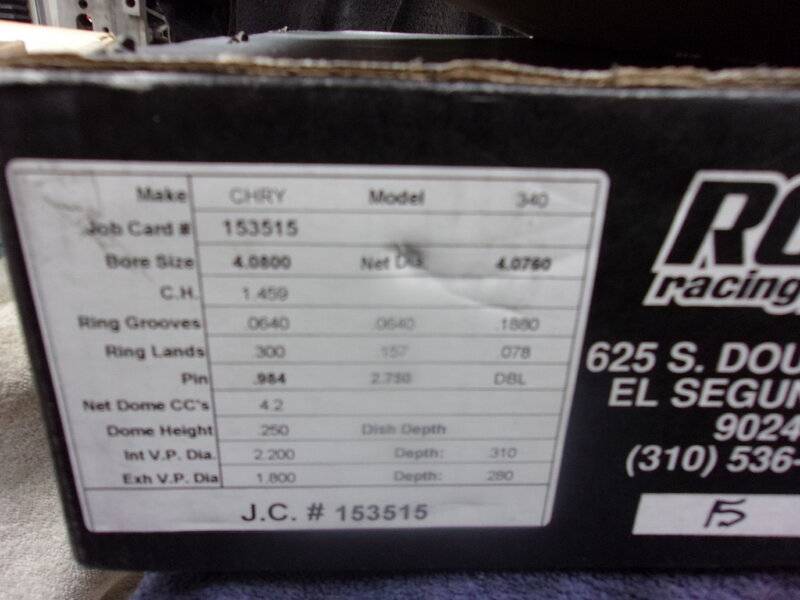

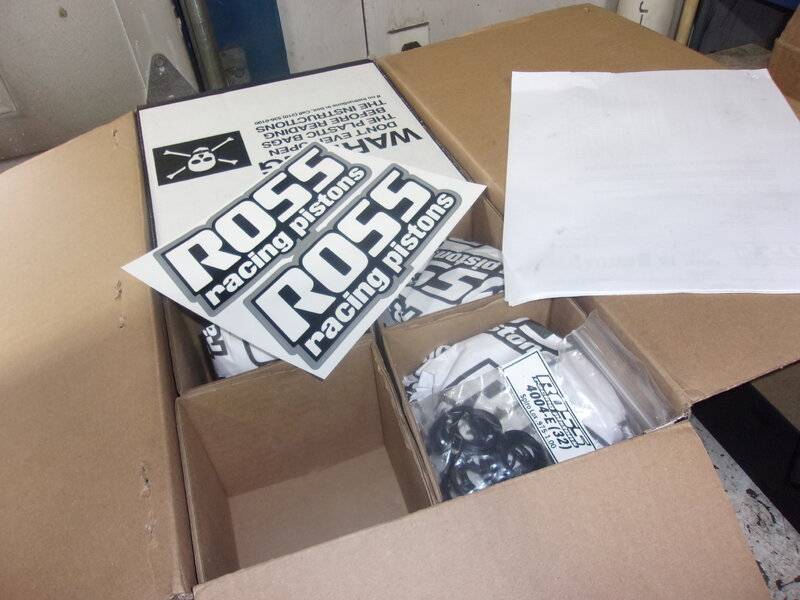

The pistons ,rods, crank, springs, retainers, are here. As soon as all the parts are here he said he'll take the 416 apart and bore the block He is also truing and bushing the lifter bores.

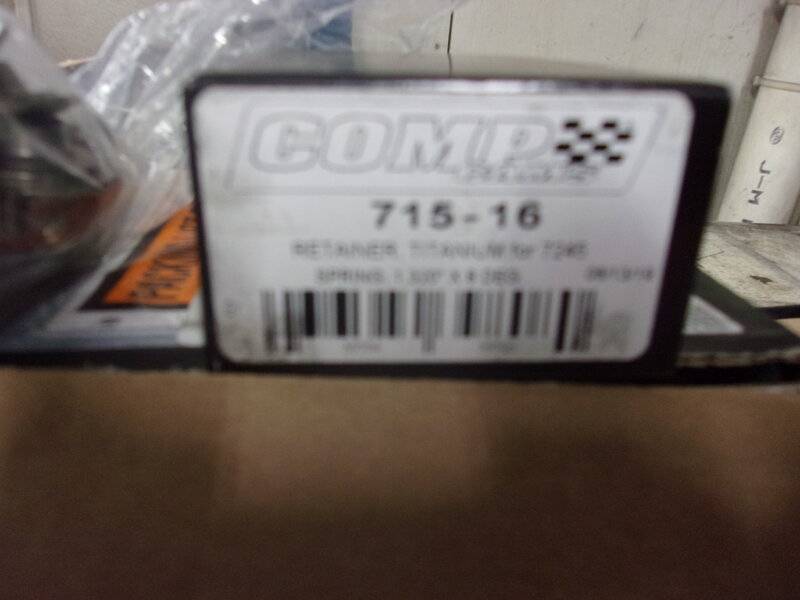

Waiting for titanium valves and large Diameter Offset solid roller lifters. The rods and crank are supper light. I think the plastic bag weighs more then the retainers.

Waiting for titanium valves and large Diameter Offset solid roller lifters. The rods and crank are supper light. I think the plastic bag weighs more then the retainers.