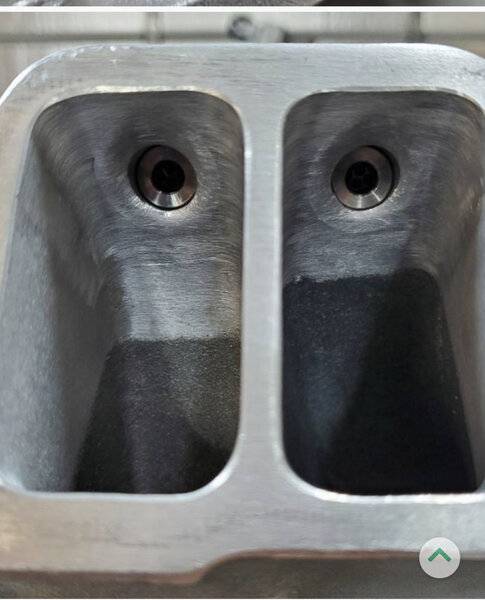

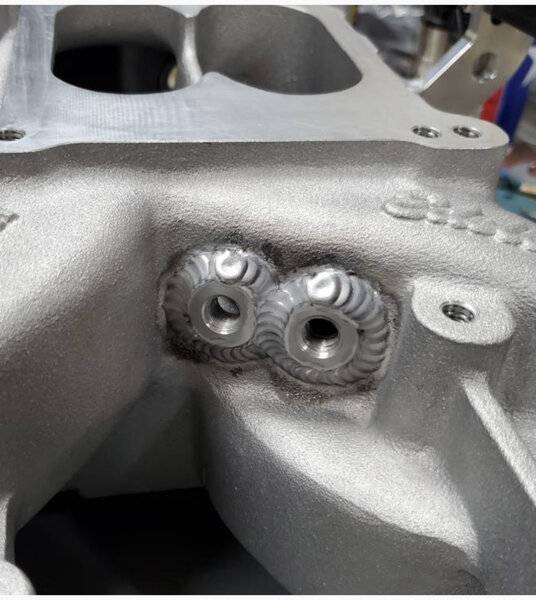

A Moparts member sent a dual plane intake To Wilson to have it gasket matched to a pattern he sent. Here are some before and after pictures of what he paid just under 300.00 to have done. Damn this makes my head spin. The price listed above did not include the bung welding.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Man I gotta raise what I charge to port intakes

- Thread starter pittsburghracer

- Start date

-

If I'm buying I expect a discount but yes, you should charge good money for what you do.

Skilled labor like this is worth more. You have years of experience.

how much time does this take you to complete one?

Gasket match on a dual plane like this probably 1.5 hours max. Prep and cleanup included but I work slow.

Should be worth $150 at least.Gasket match on a dual plane like this probably 1.5 hours max. Prep and cleanup included but I work slow.

MOPAROFFICIAL

Oogliboogli

If only , right? LOLGasket match on a dual plane like this probably 1.5 hours max. Prep and cleanup included but I work slow.

Gravy.

famous bob

mopar misfit

If only , right? LOL

Gravy.

why pay for something you can do urself ??

What !! Me ? Not me, I don't know how to Bob, and I bet watching videos on it will help , but not ever going to attempt this, having the right tools and experience would be the way to go, let @pittsburghracer do it rightwhy pay for something you can do urself ??

What !! Me ? Not me, I don't know how to Bob, and I bet watching videos on it will help , but not ever going to attempt this, having the right tools and experience would be the way to go, let @pittsburghracer do it right

I’m not going to say it’s a job everyone should attempt or do but man Dont charge someone 300.00 to remove less than one 1/8 inch of material. I would feel guilty charging 80.00 to do that but it has to be worth your while.

Hourly rate multiplied by the time invested. Seams like a fair price for port matching without the welding.

Last edited by a moderator:

Yeah plumber charged me $500 to come out for an hour to unclog the sewer line to the main (tree roots - it cost $400 last year). Nobody will get out of bed for a few hundred bucks up here.**** nobody wants to pay us nothing in this trade. But if you're a plumber you make a bunch of $$$ and you don't have 1% of the skill most of us have. (no ding on any trade here just an example) I can weld, braze, sweat pipe, fabricate, wrench etc. and I might as well be a Walmart greeter.

Scody21

Just send it

Shop rate for dealers like Porsche are over 200 an hour. A buddy is a refer tech and they are 180 an hour. Another buddy has a small auto shop and is booked about 3 weeks out cus they are the cheapest in town at 150 an hour.

Ya a friend of mine is the service manager at a large GM dealer and he can’t keep good techs they work a couple of weeks get there pay and quit. They get paid by flat rate hour. That’s why my career at dealers were short even in the early 80’s. Last time I was up there they were at $110.00 and I think the high pay was 44.00 per FLAT rate hr.

mopowers

Well-Known Member

Stupid question, but is gasket matching an intake even worth the effort if the rest of the intake runner is smaller than the port opening? Seems like the port is only opened up for a couple inches before the gasket. Wouldn't that sudden increase in volume slow the air speed entering the intake port in the cyl head?

Last edited:

Stupid question, but is gasket matching an intake even worth the effort if the rest of the intake runner is smaller than the port opening? Seem like the port is only opened up for a couple inches before the gasket. Wouldn't that sudden increase in volume slow the air speed entering the intake port in the cyl head?

I will say only one time did I just gasket match an intake. And that was probably the hardest I ever worked on a gasket match because number one it was a small block Ford. Number two is his class rules allowed it but all blending had to be done within 3/4 of an inch. That didn’t give you much room to blend everything in. Is gasket matching worth it??? How much are you spending to do it??? That dual plane above was going on my car before I would spend that much money for that job. If you were only going to do this job once in your life even buying a cheap grinder and router speed control, a 40.00 burr from Summit, most people have a scribe but if not you should, black magic marker can be substituted for blueing, and you need gaskets anyway. Those parts even on sale are 125.00-150.00 probably now. Then what is your time worth. To me nothing beats doing something myself. I really skirted around your question so is it worth it? To me it is because much like a head from the plenum entrance to the exit the floor goes slightly up, the roof goes slightly down, and the walls go slightly in. So me personally I want to open up that funnel.

Stupid question, but is gasket matching an intake even worth the effort if the rest of the intake runner is smaller than the port opening? Seem like the port is only opened up for a couple inches before the gasket. Wouldn't that sudden increase in volume slow the air speed entering the intake port in the cyl head?

In simple terms it wouldn't hurt.I will say only one time did I just gasket match an intake. And that was probably the hardest I ever worked on a gasket match because number one it was a small block Ford. Number two is his class rules allowed it but all blending had to be done within 3/4 of an inch. That didn’t give you much room to blend everything in. Is gasket matching worth it??? How much are you spending to do it??? That dual plane above was going on my car before I would spend that much money for that job. If you were only going to do this job once in your life even buying a cheap grinder and router speed control, a 40.00 burr from Summit, most people have a scribe but if not you should, black magic marker can be substituted for blueing, and you need gaskets anyway. Those parts even on sale are 125.00-150.00 probably now. Then what is your time worth. To me nothing beats doing something myself. I really skirted around your question so is it worth it? To me it is because much like a head from the plenum entrance to the exit the floor goes slightly up, the roof goes slightly down, and the walls go slightly in. So me personally I want to open up that funnel.

mopowers

Well-Known Member

I will say only one time did I just gasket match an intake. And that was probably the hardest I ever worked on a gasket match because number one it was a small block Ford. Number two is his class rules allowed it but all blending had to be done within 3/4 of an inch. That didn’t give you much room to blend everything in. Is gasket matching worth it??? How much are you spending to do it??? That dual plane above was going on my car before I would spend that much money for that job. If you were only going to do this job once in your life even buying a cheap grinder and router speed control, a 40.00 burr from Summit, most people have a scribe but if not you should, black magic marker can be substituted for blueing, and you need gaskets anyway. Those parts even on sale are 125.00-150.00 probably now. Then what is your time worth. To me nothing beats doing something myself. I really skirted around your question so is it worth it? To me it is because much like a head from the plenum entrance to the exit the floor goes slightly up, the roof goes slightly down, and the walls go slightly in. So me personally I want to open up that funnel.

I appreciate it, but that didn't really answer my question. Probably my fault though. What I meant was more - Could gasket matching a port opening in the intake and cylinder head be detrimental to making power if the rest of the port on the intake and cylinder head are left untouched (ie. smaller than the gasket section of the port)?

I've got the tools and know-how to do it and have done it multiple times. I'm just curious if it's even worth the effort if ultimately the result is a port cross-sectional area that opens up and necks back down. I guess it would depend on the amount the port needs to be opened up to match the gasket?

I appreciate it, but that didn't really answer my question. Probably my fault though. What I meant was more - Could gasket matching a port opening in the intake and cylinder head be detrimental to making power if the rest of the port on the intake and cylinder head are left untouched (ie. smaller than the gasket section of the port)?

I've got the tools and know-how to do it and have done it multiple times. I'm just curious if it's even worth the effort if ultimately the result is a port cross-sectional area that opens up and necks back down. I guess it would depend on the amount the port needs to be opened up to match the gasket?

If you were only going to open the head port entrance without addressing “the pinch” I honestly think you are doing more bad than good.

Unless your doing new construction, plumbing and electrician trades some times do nasty work in unsanitary conditions like crawling in a tight space attic in deplorable heat to work. No thank you, just say no, I am neither nor do I want to be. I can see why they make the money they do.**** nobody wants to pay us nothing in this trade. But if you're a plumber you make a bunch of $$$ and you don't have 1% of the skill most of us have. (no ding on any trade here just an example) I can weld, braze, sweat pipe, fabricate, wrench etc. and I might as well be a Walmart greeter.

MOPAROFFICIAL

Oogliboogli

I was trying to say that I would take $300 all day long for a gasket match.why pay for something you can do urself ??

Your name has to be Wilson to get the 300. lol

I was trying to say that I would take $300 all day long for a gasket match.

That’s what I charge to port the whole intake. Lol.

Kinda like greasy motors, filthy diesels, crawling under the dash, lifting transmissions, locating electrical issues (even on 22 Denali's) lifting 100 pound dually tires, brake dust and sooo much more. Not even counting all the chemicals and dust. Mechanic's sure are due much more respect.Unless your doing new construction, plumbing and electrician trades some times do nasty work in unsanitary conditions like crawling in a tight space attic in deplorable heat to work. No thank you, just say no, I am neither nor do I want to be. I can see why they make the money they do.

MOPAROFFICIAL

Oogliboogli

No one wants to pay for powerThat’s what I charge to port the whole intake. Lol.

No one wants to pay for power

I’ve been about as busy as I want to be. This set should be done early week and I was just going to grab a set of Speedmaster heads that I bought to port and sell but I got another job last night. Sounds like both heads and intake again.

-