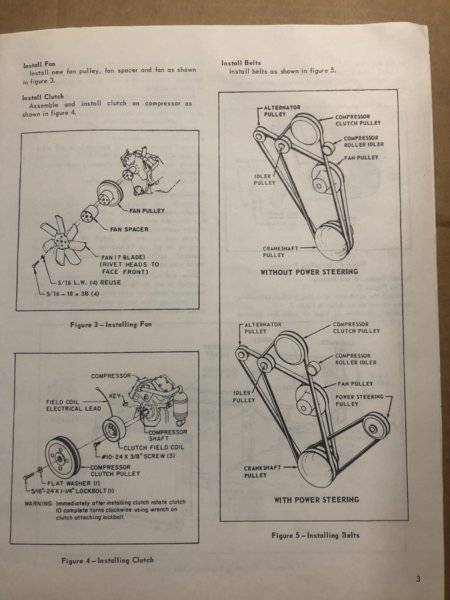

The routing for the belts is different for ‘65 & ‘66 273 engines. The ‘65 has two belts for the AC compressor & alternator. While the ‘66 uses one belt for AC with two pulleys.

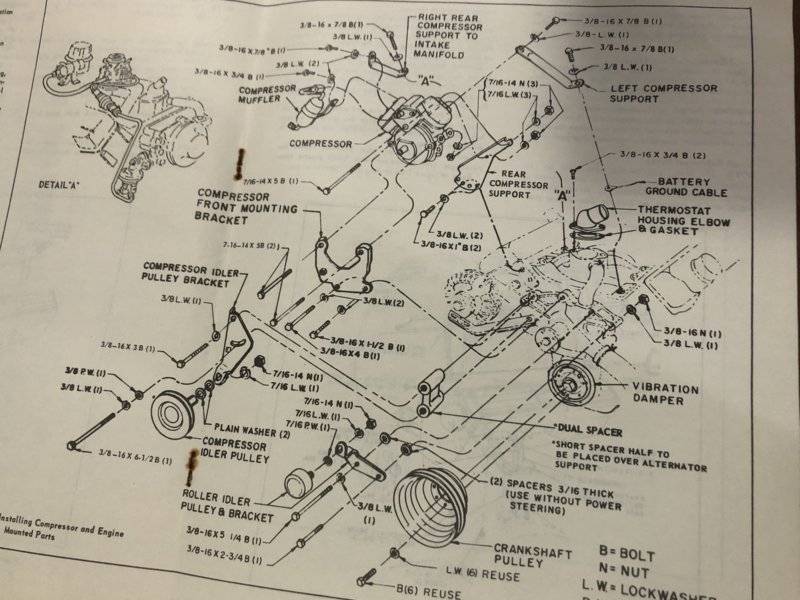

This is a pic of a ‘65 Dart on Craigslist & a diagram of a ‘66 dealer installed AC.

For ‘66 it looks like they added two pulleys to go to one belt with more belt wrap on the compressor instead of the dual belts used on the ‘65s.

This is a pic of a ‘65 Dart on Craigslist & a diagram of a ‘66 dealer installed AC.

For ‘66 it looks like they added two pulleys to go to one belt with more belt wrap on the compressor instead of the dual belts used on the ‘65s.

Last edited: