You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HEI Upgrade but No Spark (kinda)

- Thread starter Ian McCrimmon

- Start date

-

Ian McCrimmon

Well-Known Member

Yes. It has two little tabs that I drilled holes into the heat sink in order for it to lay flat. Have it grounded but will remove it so I can add some thermal paste underneath.So module was bad? Make certain it is mounted "flat" and properly heat sinked

Now I am getting fuel pouring out the top of the carb so time to re-check the float level and the seat for debris. But it lives!

Now I am getting fuel pouring out the top of the carb so time to re-check the float level and the seat for debris. But it lives!

I had that same issue with the BBS on my 225 last year. It turned out to be the brass float leaking and letting gas inside, not allowing the needle to seat. i replaced it with a NOS float from Daytona Carb.

I don't understand why it failed after "only" 54 years.

Ian McCrimmon

Well-Known Member

Well so far I have pulled the top of the carb off only to find a lot more debris in the bowl than I expected. Earlier I rebuilt the carb and cleaned it out but either the fresh fuel stirred up hidden debris or the old filter and fuel lines need cleaning and/or replacing.

Discovered that the float baffle wasn't sitting flush with the top of the carb bowl assembly so I filed the tabs down just enough to sit flush at the top.

And lastly the float was hitting the baffle before closing the needle thus the needle never seated completely and kept filling the bowl. Turns out it was bent way too much-even though the float level was correct it was only correct because it was hitting the baffle before the needle so I replaced with the original float (replaced it earlier with one from a 318). At least it was straight in the correct spots.

I now stink of gas. And I only have two PBR left. First world problems-it's a holiday in Alberta (Heritage Day) so good luck finding a beer store open. I sooooo wish I could go to the local c-store like other places in the civilized world.

Discovered that the float baffle wasn't sitting flush with the top of the carb bowl assembly so I filed the tabs down just enough to sit flush at the top.

And lastly the float was hitting the baffle before closing the needle thus the needle never seated completely and kept filling the bowl. Turns out it was bent way too much-even though the float level was correct it was only correct because it was hitting the baffle before the needle so I replaced with the original float (replaced it earlier with one from a 318). At least it was straight in the correct spots.

I now stink of gas. And I only have two PBR left. First world problems-it's a holiday in Alberta (Heritage Day) so good luck finding a beer store open. I sooooo wish I could go to the local c-store like other places in the civilized world.

Ian McCrimmon

Well-Known Member

So reloaded the beer fridge and put everything back together and started attempting to start it. A splash of gas down the carb and it starts and runs until the gas is used up. So a jerry can with some fresh gas and dipped a hose from the fuel pump into it and I can get it started with two pumps on the go pedal but after a few seconds of running it dies. Haven't got around to setting the timing yet but I suspect it's out more than just a bit.

So now the question is rotor phasing. (Maybe time for a new thread!).

With the electronic distributor should the rotor point almost exactly at the cap terminal when the reductor is in line with the pick up? Mine is out more than just a degree or two-more like 3/4" or so from straight up. I marked on the distributor body the plug terminals and thats how I see it's out that much. And being out that much there isnt enough adjustment in the slotted plate on the distributor. Sorry but I cant recall if its advanced or retarded but I would think it should be pretty closed to straight up no?

So now the question is rotor phasing. (Maybe time for a new thread!).

With the electronic distributor should the rotor point almost exactly at the cap terminal when the reductor is in line with the pick up? Mine is out more than just a degree or two-more like 3/4" or so from straight up. I marked on the distributor body the plug terminals and thats how I see it's out that much. And being out that much there isnt enough adjustment in the slotted plate on the distributor. Sorry but I cant recall if its advanced or retarded but I would think it should be pretty closed to straight up no?

Ian McCrimmon

Well-Known Member

So time to update and ask for help here. PSA incoming wall of text!

I did post up pics earlier here somewhere but after getting it started I was going to set the valves and install a new valve cover gasket when I found a bent pushrod. After replacing it and installing the cork gasket I went about re-setting the float level on the carb and cleaning it out again. I also did the fuel line mod to keep it from vapor locking.

Unfortunately I can't get spark again. I followed the HEI upgrade instructions listed on slantsix.org and it did fire before but now no spark.

Same issue as before-a timing light won't flash until I release the key then it flashes once.

So to isolate some components I started swapping components and trying to get a spark.

Swapped coils twice, HEI modules four times, magnetic pickups three times all to no avail (all were used junkyard parts).

The coils both measure out at 0.6 ohms resistance and all the pick ups (set at .008 air gap with brass feeler) are around 250 ohms give or take. I ran a jumper wire across the ballast resistor as well.

I get battery voltage at the coil and from the signal from the ignition wire with key on/start.

Pulled the dissy and then tried spin testing it-still no spark.

I then tried using the old coil to eliminate the e-coil as a source of issue and hot wired from battery power and spin tested again. No dice.

This leaves me to believe the distributor is the problem but why would it run previously and now it's dead? Can't wrap my head around it!

Oh I should mention-I converted a points distributor to an electronic distributor. How-well it's totally butch but I ground down the old points block to a diameter to fit the (new) reluctor to fit upside down over the top. Drilled a hole and pressed in the roll pin. And cut down the rotor to fit under the cap.

I will take some wiring pics later today but my next step is a different distributor (which I have a WTB ad in the classified forum here).

Some pics I do have of the frankenstein distributor.

I did post up pics earlier here somewhere but after getting it started I was going to set the valves and install a new valve cover gasket when I found a bent pushrod. After replacing it and installing the cork gasket I went about re-setting the float level on the carb and cleaning it out again. I also did the fuel line mod to keep it from vapor locking.

Unfortunately I can't get spark again. I followed the HEI upgrade instructions listed on slantsix.org and it did fire before but now no spark.

Same issue as before-a timing light won't flash until I release the key then it flashes once.

So to isolate some components I started swapping components and trying to get a spark.

Swapped coils twice, HEI modules four times, magnetic pickups three times all to no avail (all were used junkyard parts).

The coils both measure out at 0.6 ohms resistance and all the pick ups (set at .008 air gap with brass feeler) are around 250 ohms give or take. I ran a jumper wire across the ballast resistor as well.

I get battery voltage at the coil and from the signal from the ignition wire with key on/start.

Pulled the dissy and then tried spin testing it-still no spark.

I then tried using the old coil to eliminate the e-coil as a source of issue and hot wired from battery power and spin tested again. No dice.

This leaves me to believe the distributor is the problem but why would it run previously and now it's dead? Can't wrap my head around it!

Oh I should mention-I converted a points distributor to an electronic distributor. How-well it's totally butch but I ground down the old points block to a diameter to fit the (new) reluctor to fit upside down over the top. Drilled a hole and pressed in the roll pin. And cut down the rotor to fit under the cap.

I will take some wiring pics later today but my next step is a different distributor (which I have a WTB ad in the classified forum here).

Some pics I do have of the frankenstein distributor.

67Dart273

Well-Known Member

I would say "simplify the problem" and "build a jig."

What is the absolute minimum you need to test components and make spark?

1...Mounting/ heat sink for the HEI module, and of course a working module. Mount it flat, remove the protrusion from the case, and consider using thermal compound.

2.....Distributor. Maybe the conversion is the problem. Examine the reluctor for strike damage and set the gap, checking it with vacuum pumped up so the gap is proper and so you can check gap change. Make certain the reluctor is not striking the pickup, nor that the bushing play is so much that it moves over, increased the gap and won't trigger. Suspect the 2 wire pickup connector. they can be troublesome. Must be clean and tight fitting.

3...Coil. for testing, coils are not finicky as to type, but of course you need a "good" as in proper functioning. When I ran the 4 pin HEI on my Dart I used the factory stock Mopar coil!!!! (And no resistor)

4...Spark gap. NEVER test or run ANY electronic ignition with an open coil connection or with a plug wire pulled loose. This creates tremendous spike/ high voltage energy which feeds back in the coil primary circuit and can damage/ destroy the module. "Rig" a spark gap at the coil tower and use WIRE core wire. THE COIL CASE is NOT the coil ground (if metal) The NEG battery (car body) is where you want to ground your test gap.

5....Wiring/ connections. Make CERTAIN the module is grounded at the mounting bolts at the heat sink, TO THE BATTERY. The module + and coil + of course go to battery + SUSPECT A TACH WIRE. Disconnect ANY other wire going to coil NEG other than the module wire, and disconnect any radio supression cap "for now" for troubleshooting Might even want to measure some voltages maybe you have a simple "bad crimp" or wire splice.

What is the absolute minimum you need to test components and make spark?

1...Mounting/ heat sink for the HEI module, and of course a working module. Mount it flat, remove the protrusion from the case, and consider using thermal compound.

2.....Distributor. Maybe the conversion is the problem. Examine the reluctor for strike damage and set the gap, checking it with vacuum pumped up so the gap is proper and so you can check gap change. Make certain the reluctor is not striking the pickup, nor that the bushing play is so much that it moves over, increased the gap and won't trigger. Suspect the 2 wire pickup connector. they can be troublesome. Must be clean and tight fitting.

3...Coil. for testing, coils are not finicky as to type, but of course you need a "good" as in proper functioning. When I ran the 4 pin HEI on my Dart I used the factory stock Mopar coil!!!! (And no resistor)

4...Spark gap. NEVER test or run ANY electronic ignition with an open coil connection or with a plug wire pulled loose. This creates tremendous spike/ high voltage energy which feeds back in the coil primary circuit and can damage/ destroy the module. "Rig" a spark gap at the coil tower and use WIRE core wire. THE COIL CASE is NOT the coil ground (if metal) The NEG battery (car body) is where you want to ground your test gap.

5....Wiring/ connections. Make CERTAIN the module is grounded at the mounting bolts at the heat sink, TO THE BATTERY. The module + and coil + of course go to battery + SUSPECT A TACH WIRE. Disconnect ANY other wire going to coil NEG other than the module wire, and disconnect any radio supression cap "for now" for troubleshooting Might even want to measure some voltages maybe you have a simple "bad crimp" or wire splice.

Ian McCrimmon

Well-Known Member

Here are a few points to mention:

I have a heat sink for the HEI module and have tested for ground but have not run a ring terminal from the module ground to battery ground.

The coils are from Ford (one from a Merkur the other from a Supercoupe).

All wiring that doesn't terminate in a crimp connector has been soldered and heat shrink wrapped. I used factory connectors where possible. What I haven't done is to test the two wire connector to see if the signal is passing from the pickup to the HEI module. Will test that.

The coil connector has a tach output wire that I cut and deadheaded.

My frankenstein distributor has a new reluctor and as mentioned I set the gap with brass feelers. As far as spin testing I used an old plug wire that I cut in half and inserted inside a clear vinyl tube. I then adjusted the ends to provide a small gap so I can see the spark. Most of my testing has been with a complete setup but using a timing light to sense a signal. I tried spin testing using the old coil and with an old grounded plug.

Check out these pics of the wiring-don't laugh as the car is supposed to look sketchy! I scrounged a lot of German car parts in my travels and utilized a lot of them like my electric power distribution (VW) and the mega fuse holder (BMW).

I have a heat sink for the HEI module and have tested for ground but have not run a ring terminal from the module ground to battery ground.

The coils are from Ford (one from a Merkur the other from a Supercoupe).

All wiring that doesn't terminate in a crimp connector has been soldered and heat shrink wrapped. I used factory connectors where possible. What I haven't done is to test the two wire connector to see if the signal is passing from the pickup to the HEI module. Will test that.

The coil connector has a tach output wire that I cut and deadheaded.

My frankenstein distributor has a new reluctor and as mentioned I set the gap with brass feelers. As far as spin testing I used an old plug wire that I cut in half and inserted inside a clear vinyl tube. I then adjusted the ends to provide a small gap so I can see the spark. Most of my testing has been with a complete setup but using a timing light to sense a signal. I tried spin testing using the old coil and with an old grounded plug.

Check out these pics of the wiring-don't laugh as the car is supposed to look sketchy! I scrounged a lot of German car parts in my travels and utilized a lot of them like my electric power distribution (VW) and the mega fuse holder (BMW).

crooked1/2dozen

Well-Known Member

I wonder if it ever ran after the engine change. Probably a small problem, perhaps exacerbated by your well intentioned changes. Possibly a ballast resistor wiring or failure based on switch response of timing light. I'm in Calgary, and have a points distributor to achieve running status, but only after checking previous changes. People think electrical is hard, but after owning a Saab and 2 Triumphs, one 2 wheeled and 1 4 wheeled, you learn!

Dan

Dan

Ian McCrimmon

Well-Known Member

Well I would appreciate any help you can provide!

I have located a used electronic distributor being brought into Calgary this weekend. As long as the weather holds you are welcome to stop over so we can go over things.

I have located a used electronic distributor being brought into Calgary this weekend. As long as the weather holds you are welcome to stop over so we can go over things.

67Dart273

Well-Known Member

When you are experiencing a no-spark situation, carefully DO NOT wiggle or disturb the distributor pickup connector. Carefully pull the pickup connections loose at the HEI and measure with an ohmeter. This might tell you if you have a problem in the 2-wire OEM dist. connector.

crooked1/2dozen

Well-Known Member

When I got my electronic distributor I also got all the wiring and control box. I wonder if you did, with factory distributor to box fittings. Makes life easier. I could help with distributor install and have a spare factory box, but factory connectors may be required. I'm inner city NW.

Ian McCrimmon

Well-Known Member

So I was able to test the two wire connector from the distributor to the HEI module and there are no issues there.

Was also able to test for voltage at the coil in the run and start positions-have voltage in both positions but just tested with a light-need to test for voltage but my multi meter is DOA.

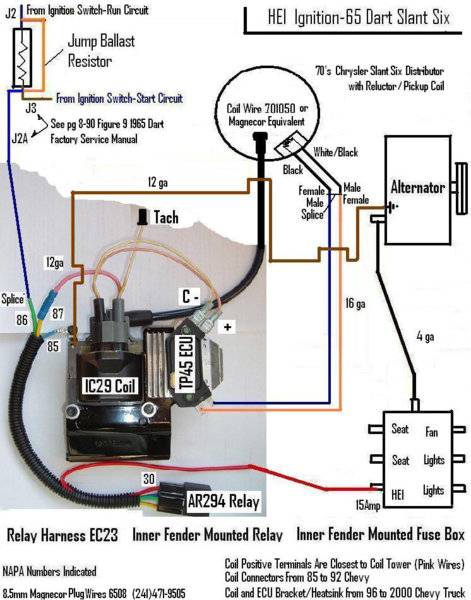

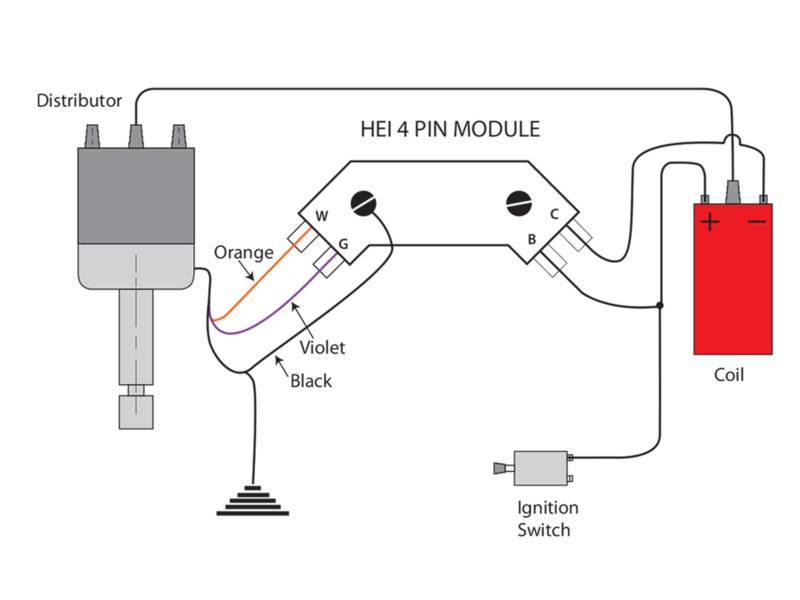

So here is what interests me-I used this diagram when wiring things up. But I have seen other sources that show a different wiring.

This diagram shows both ends of the coil going to the B side of the HEI module.

But I have seen other wiring diagrams with the B side going to coil positive and ignition run while the C side is coil negative and tach.

Can this setup run with both coil + and - going to the B side of the HEI module?

Was also able to test for voltage at the coil in the run and start positions-have voltage in both positions but just tested with a light-need to test for voltage but my multi meter is DOA.

So here is what interests me-I used this diagram when wiring things up. But I have seen other sources that show a different wiring.

This diagram shows both ends of the coil going to the B side of the HEI module.

But I have seen other wiring diagrams with the B side going to coil positive and ignition run while the C side is coil negative and tach.

Can this setup run with both coil + and - going to the B side of the HEI module?

Ian McCrimmon

Well-Known Member

Here are two I have come across.

Ian McCrimmon

Well-Known Member

Well I thought that pic showed a standard coil. But I originally wired it as the first pic as I posted. I think there may be a difference from one diagram to another. I am going to get a replacement multimeter and re-wire the coil wiring to match your picture.

It seemed odd that both HEI module ends (B and C) were wired to one coil terminal. Is that diagram wrong?

It seemed odd that both HEI module ends (B and C) were wired to one coil terminal. Is that diagram wrong?

67Dart273

Well-Known Member

You have to be specific. If you are referring to post 38, that diagram is effed up I can't see what they are doing. I will say this about coils. It's been awhile, and I no longer have the coil in question. There are "some coils" not wired as you'd expect. They have 4 terminals, and seems to me?? if I remember, that two terminals close together are NOT connected to each other at the coil, but rather are each end of the coil, and same on the other side. You have to CAREFULLY use a meter and carefully determine which two are "zero" ohms and which are actually across the coil primary winding.

Ian McCrimmon

Well-Known Member

I did wire it as per post #38.

My coil I used (both of them) have only two terminals (both from FOMOCO) and all the diagrams I see indicate the terminal with the tach wire is the negative side.

Once I get things re-wired I will try again.

My coil I used (both of them) have only two terminals (both from FOMOCO) and all the diagrams I see indicate the terminal with the tach wire is the negative side.

Once I get things re-wired I will try again.

67Dart273

Well-Known Member

I cannot understand why you even used that. It is drawn so poorly as to be useless damn near. Yes, the tach always goes to the coil NEG. The exception is something like a CDI/ MSD. In that case the tach is wired much differently, many times through a special tach adapter

Ian McCrimmon

Well-Known Member

So time for some updates.

First in reply to 67Dart273-when I first picked up the Toad I went searching for slant 6 forums and found slantsix.org first.

Later on I arrived here and find much more traffic here despite the lack of 60-62 A-body info.

I started delving into the technical discussions since I really had no idea what I had or what I was missing once I dragged it home.

One of the first things I looked into was upgrades especially with more readily available parts like the GM HEI upgrade.

So I first followed the instructions here...HEI Electronic Ignition Retrofit How-To - Slant Six Forum

I already had most of the parts required in my parts stash it went pretty quick. But the diagram I posted earlier that gave me cause for concern was the root cause of the no spark. So I referenced the pics that were posted in this thread (and confirmed elsewhere) and re-wired the electrical-coil to HEI and distributor.

Tossed in the battery, lined up TDC and confirmed the firing order and hooked up a timing light (no fuel) and cranked it over. Success! Nice flashing spark as it turns over. Really quite a simple fix but because I swore by that first diagram I assumed the problem was components not wiring.

Now time to fill the cooling system, run a fuel line to a jerry can and see if I can get a steady idle. Once I get to that point I will look at setting up my kit bash distributor or pick up one here.

First in reply to 67Dart273-when I first picked up the Toad I went searching for slant 6 forums and found slantsix.org first.

Later on I arrived here and find much more traffic here despite the lack of 60-62 A-body info.

I started delving into the technical discussions since I really had no idea what I had or what I was missing once I dragged it home.

One of the first things I looked into was upgrades especially with more readily available parts like the GM HEI upgrade.

So I first followed the instructions here...HEI Electronic Ignition Retrofit How-To - Slant Six Forum

I already had most of the parts required in my parts stash it went pretty quick. But the diagram I posted earlier that gave me cause for concern was the root cause of the no spark. So I referenced the pics that were posted in this thread (and confirmed elsewhere) and re-wired the electrical-coil to HEI and distributor.

Tossed in the battery, lined up TDC and confirmed the firing order and hooked up a timing light (no fuel) and cranked it over. Success! Nice flashing spark as it turns over. Really quite a simple fix but because I swore by that first diagram I assumed the problem was components not wiring.

Now time to fill the cooling system, run a fuel line to a jerry can and see if I can get a steady idle. Once I get to that point I will look at setting up my kit bash distributor or pick up one here.

Ian McCrimmon

Well-Known Member

Yes-I followed the first diagram (from post #38).

I had the positive coil feeding both the B and C terminals on the HEI module.

But I also had power going to the neg (and tach) coil terminal.

As you mentioned that diagram is effed up-and I printed it off and followed it as gospel. Bad move.

No issues with any components just bad wiring following a bad diagram.

I had the positive coil feeding both the B and C terminals on the HEI module.

But I also had power going to the neg (and tach) coil terminal.

As you mentioned that diagram is effed up-and I printed it off and followed it as gospel. Bad move.

No issues with any components just bad wiring following a bad diagram.

Ian McCrimmon

Well-Known Member

I agree! Even pics (or diagrams) posted online can hide details that you can't see unless you are in person.

Now to sort out my shifter built from scrap metal!

BTW here is a pic of us loading it up the day we bought it (that's me in the background).

Now to sort out my shifter built from scrap metal!

BTW here is a pic of us loading it up the day we bought it (that's me in the background).

James Clews

Well-Known Member

Ian That is a nice S series as we call them in Australia. I am not an electrician but do not understand why you guys have so many wiring issues! I have run many distributers and different alternators and never had any problems. My MSD Ecoil was the worst. if battery voltage was not at least twelve volts it would not fire. The engine would turn over but not fire. tried to start it one morning and no spark. Put my fifty dollar chineseim dissy in and it fired straight away and never ran better. would start in half a revolution of the motor every time, something the MSD would not do. I recently put an Australian Ice ign system in it but have not drag raced it yet but with the Chinese dissy has run 11.4 @ 120 mph in my car. I did have a run on issue and a not charge till I reved it over 1500 revs when I put the internal regulated alternator on it but all that needed was a resister in the charge line to the amp meter and a diode where the ballast was to prevent back feed to the ign from the alternator. Pretty simple fixes!

-