brandongjohnson

Member

Hello,

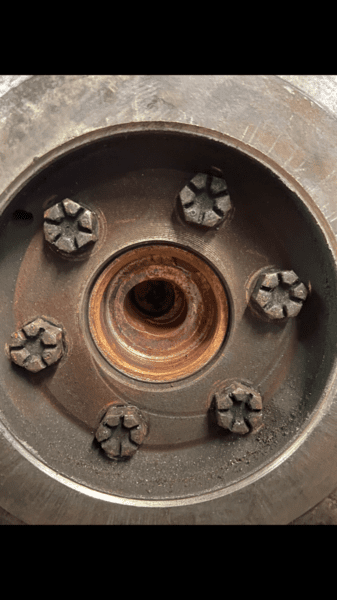

About 12 months back I picked up a 225 slant longblock from a 1968 Dart a few hours away from my house. I had it sitting in my garage, waiting for an opportunity to drop it into my truck. It was supposed to have been rebuilt recently and was basically ready for me to transfer accessories, etc over and install it. I assembled it on the stand, got everything together and ready to go. I pulled the engine off the stand to join the transmission (an a833) and install the clutch and was horrified to find this is what the end of the crankshaft looked like where the pilot bushing should go.

At this point I'll be doing a crankshaft replacement I assume. I'm not sure if the local machine shop route or buying another crank is the best bet here. From reading I'll need to track down a crank from a 1968-1976 225cid slant 6. I've found a replacement "Crankshaft kit" w/bearings from Mabbco. Dodge Chrysler 3.7 225 Crankshaft Crank Kit 1968-1976

I've read some less than stellar reviews of their entire longblocks, but wasn't sure if anyone here had used their crankshafts? I've never rebuilt the bottom end of a motor before and I don't posses most of the tools to do it, so the idea of the crank coming with matching rod and main bearings was pretty appealing. Any other suggestions on the right thing to do here? Should I just pull that crank and bring it to a machine shop? Does that look like something that they'd even be able to fix (maybe fill the crank and then re-drill the pilot bushing)?

About 12 months back I picked up a 225 slant longblock from a 1968 Dart a few hours away from my house. I had it sitting in my garage, waiting for an opportunity to drop it into my truck. It was supposed to have been rebuilt recently and was basically ready for me to transfer accessories, etc over and install it. I assembled it on the stand, got everything together and ready to go. I pulled the engine off the stand to join the transmission (an a833) and install the clutch and was horrified to find this is what the end of the crankshaft looked like where the pilot bushing should go.

At this point I'll be doing a crankshaft replacement I assume. I'm not sure if the local machine shop route or buying another crank is the best bet here. From reading I'll need to track down a crank from a 1968-1976 225cid slant 6. I've found a replacement "Crankshaft kit" w/bearings from Mabbco. Dodge Chrysler 3.7 225 Crankshaft Crank Kit 1968-1976

I've read some less than stellar reviews of their entire longblocks, but wasn't sure if anyone here had used their crankshafts? I've never rebuilt the bottom end of a motor before and I don't posses most of the tools to do it, so the idea of the crank coming with matching rod and main bearings was pretty appealing. Any other suggestions on the right thing to do here? Should I just pull that crank and bring it to a machine shop? Does that look like something that they'd even be able to fix (maybe fill the crank and then re-drill the pilot bushing)?