Talked to M&H wiring and they can make me factory correct battery cable assemblies for the old girl. Since they are not offered by Year One don't have to go through them! More info to come as the conversation only begun. Going to see if they can make a few more simple under the hood wires for a complete set of OEM looking wiring under the hood!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

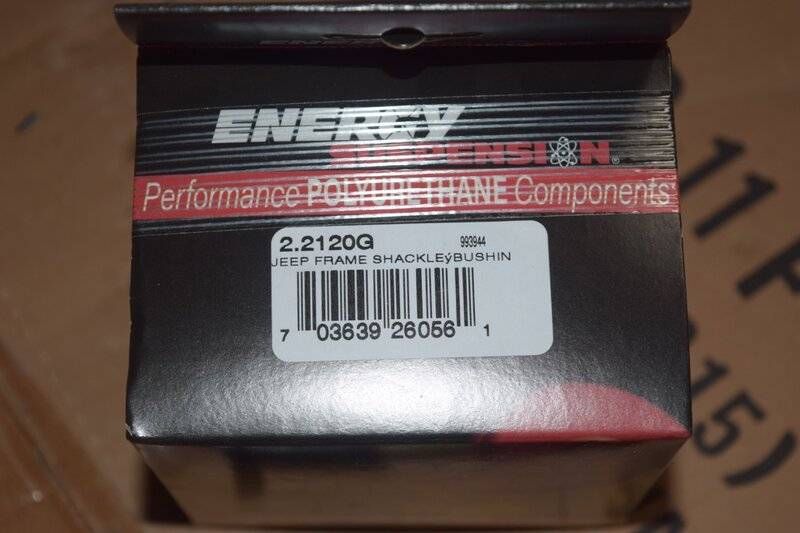

Got the rear string bushing straightened out. Here is the set you need for 1 3/8" front eyelet for the early /6 cars. Apparently there are 1 1/2" V8 car sizes in 1970. Classic Industries actually has a kit for each size which I found out after the fact so I have the 2" bushings left over... . use lots of the grease so they won't squeak later....

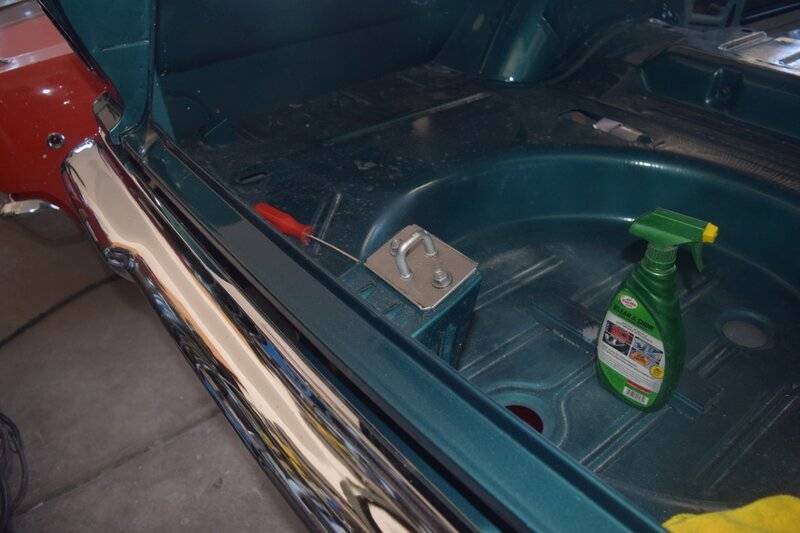

We got Cheryl's tiny rear end in as well, after a haircut! FINALLY! I worked on the back end... first was the latch for the trunk.

We got Cheryl's tiny rear end in as well, after a haircut! FINALLY! I worked on the back end... first was the latch for the trunk.

Also installed the bumper.... wow that place in Tucson did an OUTSTANDING job on that bumper, it is flawless. I spent a lot of time researching trim clips. These clips will handle most of the trim. There are smaller ones I have that will work for the trim around the bumper ends (that is at the shop getting polished) and the GT front valance trim.

Lastly a little trunk eye candy. Spare tire cover, trunk mat and wiring harness installed.

Lastly a little trunk eye candy. Spare tire cover, trunk mat and wiring harness installed.

Just a lot of little things, bead blasting and painting screws, brackets and hardware. Tanks Inc sent me the wrong strap. The part number is for a "single strap" but there are 2 of them and the bends are in the wrong place. They are right for '67 and up. A LOT of bags of bolts are now emptied! The parking break cable I ordered has a pop in grommet. There was too much side pressure and it popped out... I had ordered a DMT OEM original type with the metal tabs to hold it in (the factory did not do that because they wanted to!). Here is how to get it over the end... use a silicone tube nipple with a little tape to build it up..

Cleaned the garage out and washed the big movie star!

69_340_GTS

Well-Known Member

Single-circuit brake system kinda scares me. This would be a perfect time to upgrade!

You are doing a great job. Car looks beautiful!

You are doing a great job. Car looks beautiful!

Jim, you aren't going to know what to do with all of the free space you have once all of the parts are on the vert. LOL

Single-circuit brake system kinda scares me. This would be a perfect time to upgrade!

You are doing a great job. Car looks beautiful!

It will barely be driven. Works fine until something goes wrong with one end or the other. If this was a driver I agree. This thing will be a garage queen and any hint of any problem will get fixed immediately.

Jim, you aren't going to know what to do with all of the free space you have once all of the parts are on the vert. LOL

I am so looking forward to having some space back... I need a shop.....

I know the feeling, but I have a lot smaller space to work than you do. A lot of my stuff is stored about 2 miles from me so I'm not constantly tripping over parts that I'm not using at the moment.

I know the feeling, but I have a lot smaller space to work than you do. A lot of my stuff is stored about 2 miles from me so I'm not constantly tripping over parts that I'm not using at the moment.

That would be painful....

I've gotten used to having to shuttle parts back & forth over the last 4 years, but sometimes it's a real PITA.

Next multiple order of nickel and dime parts ordered for next weekend.... Seems like I should be getting better at this

Last edited:

mygasser

Well-Known Member

to fit the next project in?I am so looking forward to having some space back... I need a shop.....

Hi, Could you link me with where to get those kick panels?Sweet car extra nice that it's a convertible.

if you can deal with 1/16" of metal trim showing on the top part of the seal. I'd get a hardtop windshield seal and save you a bunch of $$$. 0 One side (on the inside of the car has a little smaller flange). Externally it's the same. Inside the car it's 1/16" difference( I measured a sedan also and they are the same as a hardtop.) I make a few parts for the early A's convertible too if you are in need of some. and am constantly working on other stuff when I get the time and money to R&D my stuff.

kick panels with speakers.

View attachment 1715371914

top rear side panel plastic trip

View attachment 1715371916

the top piece too!

View attachment 1715371917 View attachment 1715371918

Contact @66DvertHi, Could you link me with where to get those kick panels?

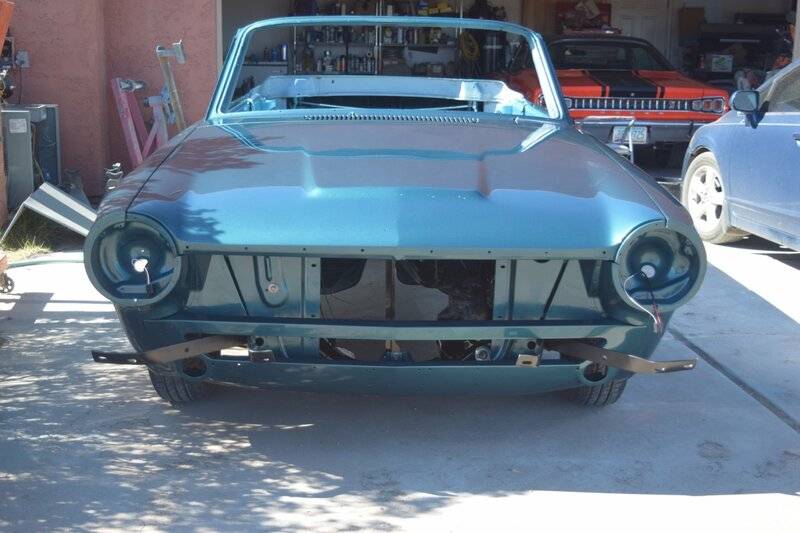

Front brakes done with the correct seals finally... and another round of buffing.... Got it with V32 and a wool pad... now just swirls and not directional scratches. A few more rounds with finer compound later..... buffing gets old.... Then I temporarly put in the torsion bars so I could get it down on the ground to work on the interior..... I really need the /6 back!

Few more glamor shots.

65barracudaLA

Well-Known Member

It really looks amazing! Are you going to paint the core support black like factory? Core support "Blackout" If I remember correctly, you didn't on your daughter's Duster.

Haven’t been able to on any of them!It really looks amazing! Are you going to paint the core support black like factory? Core support "Blackout" If I remember correctly, you didn't on your daughter's Duster.

Took the Coronet to town to get glass bead media and a battery for the Dart so I can start getting the electrical debugged in the near future! Got home and decided to stay inside today so I worked on the heater box....

Now if I can remember where all this goes..... After 2 AC boxes this thing is dirt simple.. unfortunately it was also in the worse shape of any I have done...

Simple doors all foamed

Run the bead of sealer around where the core goes and in goes the GlenRay rebuild core.

One of the hinges was broke on the vent doors so I ground off the hinge rivet and welded the tab back on. Used a regular rivet just don't tighten it all the way so it can still swing then snap off the rivet pin.

The box was in bad shape where the "J" hooks mount and the door for the vent on the box was broken out.

I cut some reinforcement metal to epoxy in.

Lot of reinforcement, not pretty but it will be strong.

Vent door rivets here, once dry I'll sand it smooth, drill 2 holes and pop rivet it back on.

Nasty stuff.

Now if I can remember where all this goes..... After 2 AC boxes this thing is dirt simple.. unfortunately it was also in the worse shape of any I have done...

Simple doors all foamed

Run the bead of sealer around where the core goes and in goes the GlenRay rebuild core.

One of the hinges was broke on the vent doors so I ground off the hinge rivet and welded the tab back on. Used a regular rivet just don't tighten it all the way so it can still swing then snap off the rivet pin.

The box was in bad shape where the "J" hooks mount and the door for the vent on the box was broken out.

I cut some reinforcement metal to epoxy in.

Lot of reinforcement, not pretty but it will be strong.

Vent door rivets here, once dry I'll sand it smooth, drill 2 holes and pop rivet it back on.

Nasty stuff.

Just a quick fix for this... cut a sheet metal patch and spread around some epoxy.

Doors are painted and foam seal installed

The DMT kit was not right for the '63 so I used extra material to cut some patches

Drill and pop rivet it in tomorrow.

All done once the epoxy dries so I can drill out the holes.

Doors are painted and foam seal installed

The DMT kit was not right for the '63 so I used extra material to cut some patches

Drill and pop rivet it in tomorrow.

All done once the epoxy dries so I can drill out the holes.

Scamp Rhonda

Well-Known Member

Man, you make it look so easy! I'm going to be going over your AC rebuild on your daughter's car. I've got that bookmarked and should help me a lot with my 72 Scamp. Thanks for all the info you've been providing. SteveJust a quick fix for this... cut a sheet metal patch and spread around some epoxy.

View attachment 1715533869 View attachment 1715533870

Doors are painted and foam seal installed

View attachment 1715533871

The DMT kit was not right for the '63 so I used extra material to cut some patches

View attachment 1715533872

Drill and pop rivet it in tomorrow.

View attachment 1715533873

All done once the epoxy dries so I can drill out the holes.

View attachment 1715533874

Man, you make it look so easy! I'm going to be going over your AC rebuild on your daughter's car. I've got that bookmarked and should help me a lot with my 72 Scamp. Thanks for all the info you've been providing. Steve

That is why I try to post as much as possible. 1) to help me out when I need to do something and forgot. 2) to help others work through their rebuilds. It helps me want to continue when someone tells me the time I have taken to document has been helpful.

Spent the morning (before it got hot) outside bead blasting the window regulators and hardware and getting them freed up and working smoothly...

Before an after....

Drilled the holes in the heater box and mounted the vent door.... All done.

Bought a battery and the hardware on the outside is too long... don't think this was for an early A body but I don't care.

Kurt's (@66Dvert) cool speaker kick panels.... need to move the dimmer switch out or drive with low beams all the time....

Before an after....

Drilled the holes in the heater box and mounted the vent door.... All done.

Bought a battery and the hardware on the outside is too long... don't think this was for an early A body but I don't care.

Kurt's (@66Dvert) cool speaker kick panels.... need to move the dimmer switch out or drive with low beams all the time....

Last edited:

-