You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Plymouth Valiant First Gen HEMI

- Thread starter Mike P 52

- Start date

-

You can hit reply in the lower RH corner above the check mark and red X. That way your replies are a little clearer

I had 2 virgin 1956 354 Hemis, always stored inside. I looked into putting one in my brothers 67 Barracuda. Jim from Racer Brown took me to look at two A-Bodies with 354 Hemis in them running. Really nice cars, but when I learned what they did to get them in there I decided that was not the vision I had for the 67 Barracuda. Custom headers I figured on, spacing the K frame an inch or two lower and inner fender clearancing, not so much. I'm pretty sure it would be a piece of cake to put one in a B or E body.

As for scrapping an early hemi, sounds nuts to me. They are still worth good money to a lot of people. I'm currently building a 341 Desoto Hemi for the 67 Barracuda. Good luck.

I had 2 virgin 1956 354 Hemis, always stored inside. I looked into putting one in my brothers 67 Barracuda. Jim from Racer Brown took me to look at two A-Bodies with 354 Hemis in them running. Really nice cars, but when I learned what they did to get them in there I decided that was not the vision I had for the 67 Barracuda. Custom headers I figured on, spacing the K frame an inch or two lower and inner fender clearancing, not so much. I'm pretty sure it would be a piece of cake to put one in a B or E body.

As for scrapping an early hemi, sounds nuts to me. They are still worth good money to a lot of people. I'm currently building a 341 Desoto Hemi for the 67 Barracuda. Good luck.

Last edited:

might be desirable for some, but they were never considered a hi-performance street engine. As far back as I can remember, (in the 70's) the Stage 1 Hemis were considered boat anchors. but also the boneyards were full of B/RB Magnum complete engines for cheap.

Mike P 52

Active Member

"....... I'm just tryin' to be helpful...."

Denny your insights have been extremely helpful and I really do appreciate your honest input.

Guys I'm no under allusions about the first generation HEMIs. I currently have 2 in driving vehicles. To me and a lot of people they are an impressive looking motor when you open the hood and as 66fs said they’re still worth decent money even as a core/builder.

That said when you pull those big impressive heads off, you're basically looking at a small block. In the case of the engine I have built for this project a small block with 354 cubic inches. The strong point of the Gen 1s has always been their POTENTIAL to make good power numbers. Price of admission on these engines has always been high (relatively speaking), doing the work to realize their potential is an expensive and time consuming project. Even more so now when you consider you can buy a pullout engine that makes more power out of the box without the size and weight penalty.

The motor for this project was put together to be a reliable pump gas street motor capable of daily driving and even cross country cruising, not a race motor. It should be fun especially if I can also manage to get the 46RH into it with about a 4.30 gear, but a serious car…..naw.

I’ve done a fair number of swaps over the years, from ones that pretty much just fell together, to ones that took a lot of head scratching and problem solving. The problem solving is definitely my favorite part. So far I haven’t seen a show stopper on this project, but then again I haven’t started stuffing the engine in.

On a side note, I spent 1973 in Korea. After I got back to the states I walked thru a couple of junk yards and almost cried at what had been thrown away. Insult to injury was what I saw that Detroit was passing off for cars and all the imports that started showing up on the streets. That began my V8 Pinto and V8 Vega stage LOL.

Denny your insights have been extremely helpful and I really do appreciate your honest input.

Guys I'm no under allusions about the first generation HEMIs. I currently have 2 in driving vehicles. To me and a lot of people they are an impressive looking motor when you open the hood and as 66fs said they’re still worth decent money even as a core/builder.

That said when you pull those big impressive heads off, you're basically looking at a small block. In the case of the engine I have built for this project a small block with 354 cubic inches. The strong point of the Gen 1s has always been their POTENTIAL to make good power numbers. Price of admission on these engines has always been high (relatively speaking), doing the work to realize their potential is an expensive and time consuming project. Even more so now when you consider you can buy a pullout engine that makes more power out of the box without the size and weight penalty.

The motor for this project was put together to be a reliable pump gas street motor capable of daily driving and even cross country cruising, not a race motor. It should be fun especially if I can also manage to get the 46RH into it with about a 4.30 gear, but a serious car…..naw.

I’ve done a fair number of swaps over the years, from ones that pretty much just fell together, to ones that took a lot of head scratching and problem solving. The problem solving is definitely my favorite part. So far I haven’t seen a show stopper on this project, but then again I haven’t started stuffing the engine in.

On a side note, I spent 1973 in Korea. After I got back to the states I walked thru a couple of junk yards and almost cried at what had been thrown away. Insult to injury was what I saw that Detroit was passing off for cars and all the imports that started showing up on the streets. That began my V8 Pinto and V8 Vega stage LOL.

mygasser

Well-Known Member

ok, drop tube? still no inner fenders, lol.LOL Yeah Neil the thought fleetingly crossed my mind but it would definitely destroy any illusion be being inconspicuous.

neil.

might be desirable for some, but they were never considered a hi-performance street engine. As far back as I can remember, (in the 70's) the Stage 1 Hemis were considered boat anchors. but also the boneyards were full of B/RB Magnum complete engines for cheap.

That's why NHRA banned them from competition. 1st generation set so many records and easily went so fast. That's why they were used in Funny cars and Rails. Up through the 60's they didn't even run a transmission. Direct drive, floor it through the 1/4. That doesn't sound like a high performance engine to me, LOL. Always had to laugh what some people called boat anchors.

for the record, I did state...."street engine" . You can add a supercharger and nitro methane to a turd and make it fast...if it stays together.

I don't remember any kicking butt or even in the hunt in stock or super stock back in the day. Maybe you will prove me wrong, I know I am all the time....just ask my wife.

I don't remember any kicking butt or even in the hunt in stock or super stock back in the day. Maybe you will prove me wrong, I know I am all the time....just ask my wife.

Last edited:

Early Hemis were outlawed, since Chevy could not be expected to compete. The funniest was when NHRA made their GT class. They forgot to exclude the early Hemis. A guy put a NA 392 in a Duster and cleaned house and took it all. Guess what new rule was added the next year. Early Hemis were limited in quantity and were in expensive cars and trucks. Basically manufactured by Chrysler, Desoto, and Dodge from 1951-1958. The guy I got my Desoto 341 Hemi from was a street rod guy. He had a 50's Chevy with a blown 341 Desoto Hemi in it and drove that car all over the country. He had a pile of SBC, 4 bolt main, forged crank, engines outside behind his garage. He had pulled them all to be replaced with early Hemis. Including 30's Fords to a Chevy pick up. Think what you will. Just remember, Those "turds" and "boat anchors" still bring $1,000 and up for some rusted iron that has been sitting in a barn for decades.

Early Hemis were outlawed, since Chevy could not be expected to compete. The funniest was when NHRA made their GT class. They forgot to exclude the early Hemis. A guy put a NA 392 in a Duster and cleaned house and took it all. Guess what new rule was added the next year. Early Hemis were limited in quantity and were in expensive cars and trucks. Basically manufactured by Chrysler, Desoto, and Dodge from 1951-1958. The guy I got my Desoto 341 Hemi from was a street rod guy. He had a 50's Chevy with a blown 341 Desoto Hemi in it and drove that car all over the country. He had a pile of SBC, 4 bolt main, forged crank, engines outside behind his garage. He had pulled them all to be replaced with early Hemis. Including 30's Fords to a Chevy pick up. Think what you will. Just remember, Those "turds" and "boat anchors" still bring $1,000 and up for some rusted iron that has been sitting in a barn for decades.

outlawed?....what year was this? Please school me. The only Hemis I am aware of that were outlawed are the Stage II (66-71) Hemis in NASCAR.

you have peaked my curiosity on the Duster with a 392 (Stage I Hemi) in NHRA / GT class. I'm certainly no expert, but was under the impression that cars had to run the same year engine as car in that class????? I do not see how any year Duster could run a pre 60's engine in anything and be legal.

ya got anything to back up your story?

outlawed?....what year was this? Please school me. The only Hemis I am aware of that were outlawed are the Stage II (66-71) Hemis in NASCAR.

you have peaked my curiosity on the Duster with a 392 (Stage I Hemi) in NHRA / GT class. I'm certainly no expert, but was under the impression that cars had to run the same year engine as car in that class????? I do not see how any year Duster could run a pre 60's engine in anything and be legal.

ya got anything to back up your story?

Just my brain. Probably in a Car Craft article from the first year they formed the NHRA GT class. GT Class was originally any body and only cu in was the factor. I am not a drag racer, just took note of the write up. Made me chuckle. Check out trying to run a 1956 Chrysler 354 in Stock or Super Stock. Chrysler engines eligable to run "Stock" or "Super Stock" start in 1960. Most the old Gassers and rails ran early Hemis. A friend of mine collects old race cars. More than a few have either a 392 or 354. That is where my two 354's went. He wanted to get a few of them running again. One Gasser has a 354 with injection and a magneto. Both rails are Blown early Hemis, one 392 and one 354.

Still looking for an original 392 HEMI/354 Poly passenger car oil pan. They’re center sump. It shouldn’t be too bad to build one if I have to, but would prefer not to.

I’ve got some ideas on the exhaust but that will have to wait until I have the engine at least partially in the car.

I may have a 392 center sump oil pan, I'll check the dwindling stash.

Mike P 52

Active Member

"......I may have a 392 center sump oil pan, I'll check the dwindling stash....."

Thanks, I appreciate it. You might want to hold up though, I may have located one, I'll know this evening or tomorrow.

Thanks, I appreciate it. You might want to hold up though, I may have located one, I'll know this evening or tomorrow.

Thanks, I appreciate it. You might want to hold up though, I may have located one, I'll know this evening or tomorrow.

No problem, let me know and I'll check.

Super-Cuda

MOPAR .. Move Over, Plymouth Approaching Rapidly!

When I introduced myself last week and wrote what my plans were the big question was why. I guess the best answer is because it’s what I do. I’ve been a hot rodder and doing engine swaps for 50 years and I guess it’s too late to change now. As far as using a Gen 1 HEMI, I’ve been doing them for the last couple of decades and I know my way around them. That and there’s just something about opening a hood and seeing those big old HEMI valve covers.

This particular engine was built as just a solid, pump gas friendly, cruiser motor and suitable for a daily driver.

From personal experience with the 46RH and likely 4.30 gears it should get between 17 and 20 MPG at 75 MPH.

If anybody’s interested here’s a video of the engine build shortly after I finished it.

If the video doesn't play when clicking on the red icon, try clicking on the "watch on You tube " icon.

.

Man! That's so cool!!

Love the look and sound of those old Hemi's

Mike P 52

Active Member

Nope, haven’t given up yet. I got a little further last fall before it started cooling off . When it started getting cold the issues with my back pretty much kept me out of the shop most of the winter. Now that’s it’s warming up again we’re back at it.

Last fall I did find a couple of 392 pans so that issue is solved. As the motor mount lugs are the same on the early HEMI and A and LA motors I ordered a set of Schumacher small block to slant 6 conversion mounts to at least give me a starting point when I get to that point. It looks like they will be pretty close but I’ll probably have to do some mods to the frame mounts. While I was researching the mounts I found out the K frame in the 440 car is an aftermarket one set up for spool mounts. The decision has been made to go ahead and finish the mockup on the slant 6 crossmember and then swap K members between the 2 cars when we start on the green one.

I’d borrowed an empty 46RH trans case from a friend at the local transmission swap so with that and the mock-up block and heads on hand it was time for the initial test fit.

]

mock up parts[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

mock up parts[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

As we hadn’t done any transmission tunnel modifications I elected to just remove the OD housing for the initial test fit.

]

MU1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

MU1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

It’s tight but not as horrible as I thought it was going to be.

]

MU2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

MU2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

One of the first issues I ran into was interference between the engine and the steering column.

]

column 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

column 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

It looks like this might be a non-issue on the green car however . The floor shift column in that car has a lot shorter mast than the column shift one in the red car (for now we just pulled the steering column and steering shaft on the red car for mock-up). If there are issues with the steering shaft on the green car it shouldn’t be too bad to build a 2 piece shaft with U-joints if necessary. I’ll be installing an EPAS electric power steering unit in the green car, so I’ll be working on the steering column anyway.

]

column 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

column 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

And that’s about as far as we got before the weather got cold.

Last edited:

Mike P 52

Active Member

It’s finally warmed up a bit in the last couple of weeks and my backs doing a bit better now so my grandson’s been coming over to give me a hand on the car. We spent yesterday clearance the transmission tunnel for the overdrive unit on the red car (we’ll have to duplicate this on the green car but wanted to see what we we’re in for and needed it done to get everything in straight so I can finish building the motor mounts).

https://flic.kr/p/2pKhd6e]

OD 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

OD 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I’d already picked up a USCT cross member for the transmission and at the end of the day were pretty close to having the tunnel modified.

https://flic.kr/p/2pKhd69]

OD 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

OD 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

.

Mike P 52

Active Member

I tried not to completely waste the winter so I spent some time figuring out some things that I would normally do much later in the project. As I mentioned the car is being built to be a dependable long distance cruiser. That being said parts do fail.

I’m going to be running an MSD 6A box on the car. I like them for some builds and was using a MSD 6AL box on my 57 Plymouth. I had had an MSD box on another car fail just prior to doing the wiring harness on the 57 so was looking at picking up a spare MSD unit to carry with me. For me the MSD box was a little pricey to have one sitting in the trunk “just in case”. Then I would still have to remove the old MSD box mount the new one and wire it in. Not a fun prospect when you’re sitting on the side of the road in the middle of nowhere at 3AM.

Anyway I sat down and figured out the wiring I would have to do to mount and use a standard MOPAR ECU as a back-up system. I wanted it so if the MSD failed, I could simply just unplug the MSD and plug in the MOPAR ECU start the car and be on the road again. I decided I wanted to use the same system on the 68. I’d kept a copy of the wiring diagram but the wiring had changed slightly on the MSD I had from the last system I’d built (15 years ago). I started from scratch on the wiring diagram.

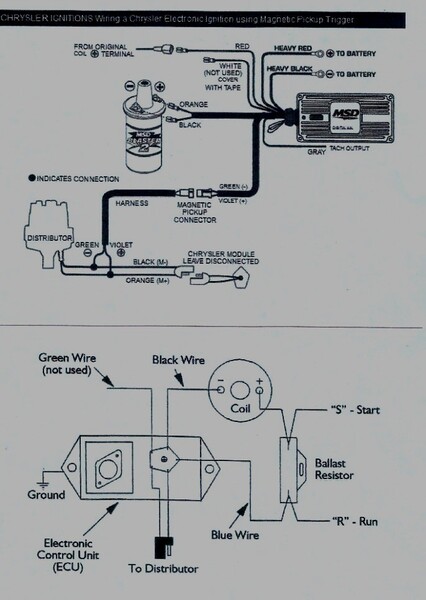

These are the factory wiring diagrams for the MSD 6A and Chrysler ECU I started with.

https://flic.kr/p/2pHtD2z]

wiring MSD CHRY org[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

wiring MSD CHRY org[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

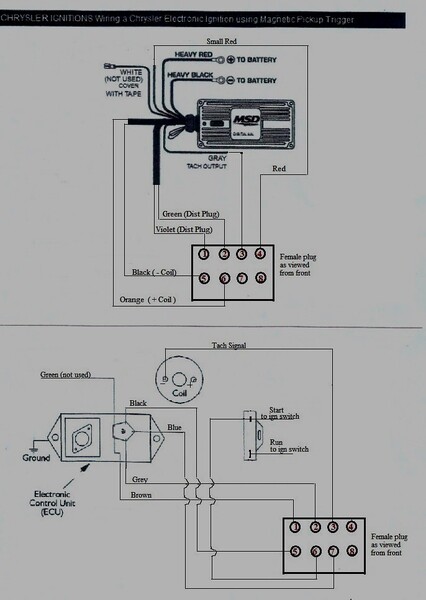

And these are the wiring diagrams where I connect the units to 8 pin plugs.

https://flic.kr/p/2pHAvxA]

wiring MSD CHRY 8[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

wiring MSD CHRY 8[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

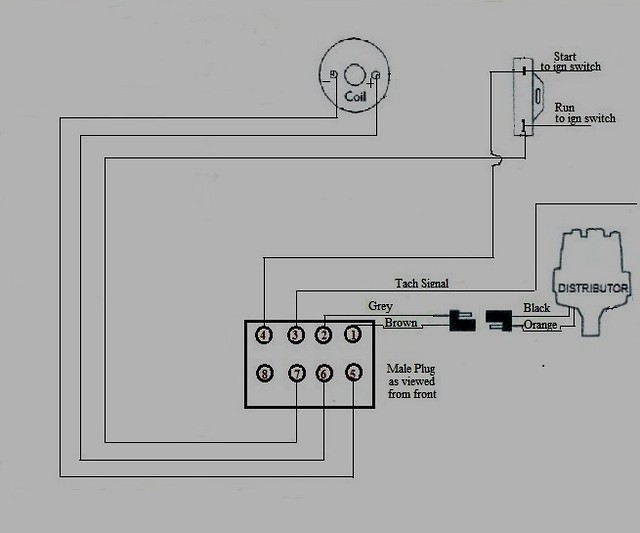

And this is the diagram showing how the wiring harness is wired to the plug either the MSD or ECU into the cars system.

https://flic.kr/p/2pHydVc]

Wiring Harness[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Wiring Harness[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

A word of caution to anyone who may want to build one of these back-up systems. These diagrams are designed for a specific MSD box going into a specific car. MSD wiring can change slightly from model to model (and the year it was built). It will be up to you to verify every circuit on your particular vehicle.

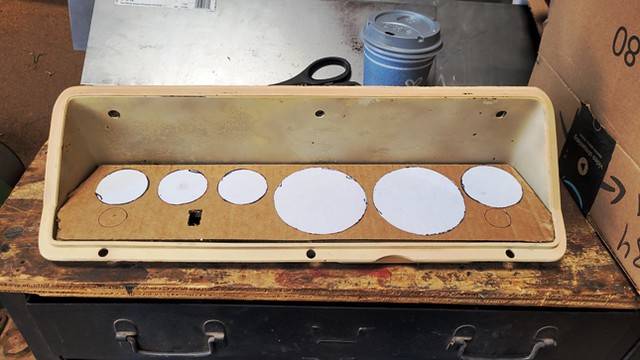

I also started looking at the dash/gauge cluster in the Green car. It might have been OK when the car was mostly on the strip, but left a bit to be desired for something that gets driven on the street on a regular basis. The factory cluster behind the tach actually looks pretty presentable, it even looks like they installed new gauges in it…..unfortunately nothing appears to be hooked up.

https://flic.kr/p/2pJKMVj]

68 Cluster 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

68 Cluster 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Oh well that’s what I built a parts car for. I didn’t mind using this for a basis to an aftermarket gauge cluster. And I could pretty much just work at the bench when my back bothered me.

https://flic.kr/p/2pJJEEh]

68 Cluster 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

68 Cluster 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I already had the speedometer, tach and 1 ½” gauge trio. I could not find a 1 ½” fuel gauge however and finally settled on a 2” gauge. Although not exactly the placement I would have liked had I found a 1 ½” fuel gauge this is what I came up with.

https://flic.kr/p/2pJJEUL]

68 cluster 3[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

68 cluster 3[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I’m using the original locations for the headlights, wipers and hazard flashers (plus added a new switch for the fuel pumps) so I needed a portion of the original back plate.

https://flic.kr/p/2pJEcqw]

68 dash 4[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

68 dash 4[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I’ve still got a little to do/re-do on it but overall I’m pretty happy with it.

https://flic.kr/p/2pKeYAT]

z GC[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

z GC[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Mike P 52

Active Member

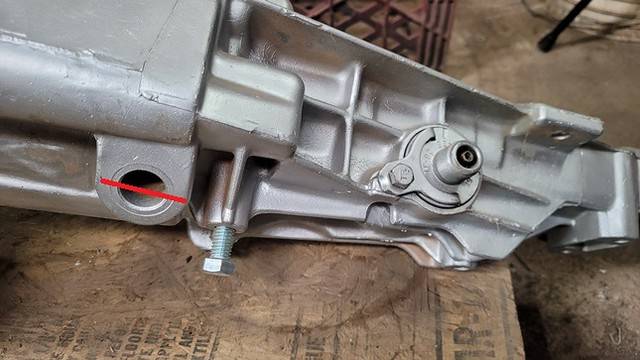

Over the weekend we got finally got the transmission located in the transmission tunnel. We had run into an issue with a boss located on the OD housing that wouldn’t allow the transmission to be centered where it needed to be. After talking to my friend at the transmission shop that I had borrowed the case from I found out that on the 46 RHs, the boss really didn’t really serve a purpose, it was cast into the case but was really just a blind hole that was plugged at the end. On the 46Res, the hole is threaded for and an electrical connector threads into the boss. I didn’t need to trim much, just the corner off of it.

https://flic.kr/p/2pLZybc]

z OD int 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

z OD int 2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

That gave us just enough to do the trick and get the transmission to fit on the aftermarket crossmember.

https://flic.kr/p/2pN5g4Y]

OD Trim[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

OD Trim[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

The transmission is pretty much dictating the location of the motor. Back any further and we start running into transmission tunnel interference issues. Forward and we’ll run into fan/radiator issues.

Early on in the project I ordered a set of Schumacher small block to /6 K member A body conversion mounts. I knew these were a Bolt-on to the 1st Gen Hemi and I figured and I figured it would give me a head start on building the mounts rather than starting from scratch.

When we set the motor down it’s about an inch too far forward to allow the motor mounts to fit into the holes in the frame mount (we cut the bottom studs off mounts for test fitting……no big deal the mounts are available and cheap). Anyway set down on the mounts the engine centers into the body where it belongs and if it wasn’t for the wide heads would be in a good location. As it is looks like the motor will have to be raised a bit, both for head and exhaust clearance. And that’s where we stopped on Sunday.

https://flic.kr/p/2pNpcgM]

S mounts[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

S mounts[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Yesterday it was back to finishing up the gauge cluster. I had gotten the headlight and wiper switches in it and overall was pretty happy with the way it turned out.

https://flic.kr/p/2pLXfrQ]

z dash d[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

z dash d[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I have 2 grandsons, the oldest one is out on his own and is a mechanic now, actually turning into a pretty good one. He’s been coming over on Sundays and helping me with those things that my back won’t let me do. I don’t think the younger grandson (13 yo) will ever be a mechanic, his interests lie in different directions (but you never know). He has shown an interest in electronics however. I’ve been working on that a bit with him just the DC stuff right now. He’s progressed where he can do wiring diagrams so yesterday we started on wiring the gauge cluster.

https://flic.kr/p/2pNgibo]

z aust wiring[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

z aust wiring[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

It was a lot of repetitious work but for his first time he did pretty good. We bench tested everything we could (everything but the tach and speedometer which needs a running engine/transducer connected to a driving car for) and everything works as it should. Actually seeing things light up and work was probably the best part for him LOL.

https://flic.kr/p/2pNgibt]

z AW2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

z AW2[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

The wiring could stand to be a bit neater but it’s functional.

.

Mike P 52

Active Member

With the transmission located we could start on the motor mounts and exhaust. I had 3 sets of factory manifolds (1 pair of 4 bolt flange truck manifolds, 2 pair of 55-56 manifolds) and a set of shorty headers. It eventually came down to a pair of the 55-56 manifolds. These are far from optimum from a performance standpoint, but from first hand experience running these on my 57 Plymouth with another mild 354 they’ll do well enough. I realize I am leaving power on the table with them but am trading that off against the time to fit and build a custom set of headers.

https://flic.kr/p/2pPutX1]

exhaust[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

exhaust[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

In the process of fitting the exhaust we ended up raising the engine a bit (probably a bit over an inch)

https://flic.kr/p/2pPuu3M]

install 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

install 1[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Besides giving the exhaust clearance we needed, it also allows enough clearance to run the aluminum valve covers I want to use. I’d already decided I was going to use an aftermarket AC/Heat combination evaporator under the dash (this works well as there is currently no heater in the green car and the fire wall hole for the blower motor was filled when the car was built). The master cylinder won’t be an issue as I have the brackets to raise it above the valve covers. There is adequate clearance to get the distributor in and out under the wiper motor. I may actually be able to run the steering shaft on a straight shot to the steering gear, but if not, it won’t be too difficult to build a 2 piece shaft with U joints to get the steering hooked up.

Next was to tack the frame mounts together, of course that was when the welder started to act up so the welds aren’t real pretty but as we’re going to remove the K member anyway I’ll be able to do some grinding and final welding before it goes into the green car.

After we got the mounts tacked in we decided to take a break from the car and start getting the 354 on the engine stand ready to install in the Green car.

The engine had a very minor oil leak from the valley cover and of course the manifold had to come off to access the bolts.

At some point I am still want to try aftermarket EFI on the car (after I get a few thousand miles on the motor). I’ve been leaning towards the Holley Sniper, and reading some of the forums on them it appears that there is an issue getting a good idle out of them with if you’re using a dual plane manifold with a full-length divider. The cure appears to be milling the divider down. Now was a good time to do this so it went over to the machine shop to have about 3/8” removed.

https://flic.kr/p/2pQX8Hq]

divider[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

divider[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

When the manifold came back from the machine shop I decided to set it on the mock-up engine and see where I was going to be as far as hood clearance went. The Hot Heads intake is tall and even before we raised the engine I suspected we’d need a hood scoop of some kind. With the engine raised it will be mandatory …….and would require a taller scoop than I would like to use.

https://flic.kr/p/2pSgNis]

zz HR[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

zz HR[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

I decided to rethink the intake in favor of something shorter, as I had a factory single 4 BBl intake laying around, I tried that one. It’s better (a bit over an inch lower), and push come to shove I can use that one with a couple of minor modifications.

https://flic.kr/p/2pSgbbG]

zz Factotry[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

zz Factotry[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

The lowest intakes I’m aware of are the 57-58 392 dual Quad units. That with a dropped base air cleaner may even let me use the stock hood without a scoop. I started putting the word out that I’m hunting for one of those or a Weiand 7263 which appears to be basically an aluminum copy of the factory intake.

https://flic.kr/p/21UKGgS]

Cad afb s[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Cad afb s[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Next we got the engine off the stand to change out the rear sump pan for the center sump 392 pan. The pans aren’t reproduced so I had to find a good used one. The fortunately it wasn’t too hard to find a decent one.

https://flic.kr/p/2pSgbfu]

zz Pans[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

zz Pans[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Unfortunately the pickup is no longer available new, and even decent used ones are hard to find. The profile of the 392 pan is similar to the 64 and up small block pans. I’m also using one of Hot Heads High Volume oil pumps (a modified 340 oil pump with a spacer). The SB pickups are readily available new I decided to see if that could be made to work.

https://flic.kr/p/2pQZBDW]

pickup[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

pickup[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

Turns out it actually fits pretty well.

https://flic.kr/p/2pSgbyA]

zz PU 3[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

zz PU 3[/url] by https://www.flickr.com/photos/153889607@N08/]M Patterson[/url], on Flickr

.

https://flic.kr/p/2pPutX1]

In the process of fitting the exhaust we ended up raising the engine a bit (probably a bit over an inch)

https://flic.kr/p/2pPuu3M]

Besides giving the exhaust clearance we needed, it also allows enough clearance to run the aluminum valve covers I want to use. I’d already decided I was going to use an aftermarket AC/Heat combination evaporator under the dash (this works well as there is currently no heater in the green car and the fire wall hole for the blower motor was filled when the car was built). The master cylinder won’t be an issue as I have the brackets to raise it above the valve covers. There is adequate clearance to get the distributor in and out under the wiper motor. I may actually be able to run the steering shaft on a straight shot to the steering gear, but if not, it won’t be too difficult to build a 2 piece shaft with U joints to get the steering hooked up.

Next was to tack the frame mounts together, of course that was when the welder started to act up so the welds aren’t real pretty but as we’re going to remove the K member anyway I’ll be able to do some grinding and final welding before it goes into the green car.

After we got the mounts tacked in we decided to take a break from the car and start getting the 354 on the engine stand ready to install in the Green car.

The engine had a very minor oil leak from the valley cover and of course the manifold had to come off to access the bolts.

At some point I am still want to try aftermarket EFI on the car (after I get a few thousand miles on the motor). I’ve been leaning towards the Holley Sniper, and reading some of the forums on them it appears that there is an issue getting a good idle out of them with if you’re using a dual plane manifold with a full-length divider. The cure appears to be milling the divider down. Now was a good time to do this so it went over to the machine shop to have about 3/8” removed.

https://flic.kr/p/2pQX8Hq]

When the manifold came back from the machine shop I decided to set it on the mock-up engine and see where I was going to be as far as hood clearance went. The Hot Heads intake is tall and even before we raised the engine I suspected we’d need a hood scoop of some kind. With the engine raised it will be mandatory …….and would require a taller scoop than I would like to use.

https://flic.kr/p/2pSgNis]

I decided to rethink the intake in favor of something shorter, as I had a factory single 4 BBl intake laying around, I tried that one. It’s better (a bit over an inch lower), and push come to shove I can use that one with a couple of minor modifications.

https://flic.kr/p/2pSgbbG]

The lowest intakes I’m aware of are the 57-58 392 dual Quad units. That with a dropped base air cleaner may even let me use the stock hood without a scoop. I started putting the word out that I’m hunting for one of those or a Weiand 7263 which appears to be basically an aluminum copy of the factory intake.

https://flic.kr/p/21UKGgS]

Next we got the engine off the stand to change out the rear sump pan for the center sump 392 pan. The pans aren’t reproduced so I had to find a good used one. The fortunately it wasn’t too hard to find a decent one.

https://flic.kr/p/2pSgbfu]

Unfortunately the pickup is no longer available new, and even decent used ones are hard to find. The profile of the 392 pan is similar to the 64 and up small block pans. I’m also using one of Hot Heads High Volume oil pumps (a modified 340 oil pump with a spacer). The SB pickups are readily available new I decided to see if that could be made to work.

https://flic.kr/p/2pQZBDW]

Turns out it actually fits pretty well.

https://flic.kr/p/2pSgbyA]

.

abdywgn

dismantler

is this the brackets used for an A-body power brake booster? A friend did that on his 66 A-body and had issues that I believe he decided was related to the pedal ratio.master cylinder won’t be an issue as I have the brackets to raise it above the valve covers.

mygasser

Well-Known Member

that could be when removing those brackets. i went to manual brakes on my 68 valiant, the pedal ratio was the same on servo and non servo so i hoped it's be ok. no..... the pedal was very hard with less travel and no feel...... or power. the pedal would need drilling closer to the pivot where the clevis connects.is this the brackets used for an A-body power brake booster? A friend did that on his 66 A-body and had issues that I believe he decided was related to the pedal ratio.

going from manual (direct on the bulkhead) to the servo type brackets will if my assumption is correct improve the brakes at the expense of a slightly 'longer' pedal travel.

neil.

Mike P 52

Active Member

“……..is this the brackets used for an A-body power brake booster? A friend did that on his 66 A-body and had issues that I believe he decided was related to the pedal ratio…….”

“…..that could be when removing those brackets. i went to manual brakes on my 68 valiant, the pedal ratio was the same on servo and non servo so i hoped it's be ok. no..... the pedal was very hard with less travel and no feel...... or power. the pedal would need drilling closer to the pivot where the clevis connects. going from manual (direct on the bulkhead) to the servo type brackets will if my assumption is correct improve the brakes at the expense of a slightly 'longer' pedal travel……”

The brackets I’m using are the set Speedway sells so it is probably the same as your friends. His belief that the issue was probably pedal ratio is probably correct, but it could also have been aggravated by using an incorrect master cylinder. Most cars call for a different master cylinder for manual vs power brakes. The manual brake cars usually have a small bore/piston size.

Pedal ratio can be a pain to figure out. Depending on the manufacture and specific car, some use a different brake pedal specific to manual or power brakes (the difference being the location of the connection point the master cylinder connects to).

Years ago I did the relocation brackets and drum to front manual disc brake conversion on a customers car. I remember it was a PIA getting the combination figured out as far as pedal ratio, master cylinder and bracket ratio…..did finally end up with a nice system though. Problem is it’s been so long ago I can’t remember even which of his cars we did it on (old age and CRS).

Fortunately, on this car I’m starting with a brake system that works well as is and just relocating the master cylinder for valve cover clearance. I just glanced at the brackets when they came in and I figured I may have to change the ratio on the brackets, which shouldn’t be any more involved than modifying the existing arm from the bracket to the master cylinder (or building a new arm) to move the connection point between the pedal and the bracket pivot higher up. Sounds good on paper anyway LOL.

.

“…..that could be when removing those brackets. i went to manual brakes on my 68 valiant, the pedal ratio was the same on servo and non servo so i hoped it's be ok. no..... the pedal was very hard with less travel and no feel...... or power. the pedal would need drilling closer to the pivot where the clevis connects. going from manual (direct on the bulkhead) to the servo type brackets will if my assumption is correct improve the brakes at the expense of a slightly 'longer' pedal travel……”

The brackets I’m using are the set Speedway sells so it is probably the same as your friends. His belief that the issue was probably pedal ratio is probably correct, but it could also have been aggravated by using an incorrect master cylinder. Most cars call for a different master cylinder for manual vs power brakes. The manual brake cars usually have a small bore/piston size.

Pedal ratio can be a pain to figure out. Depending on the manufacture and specific car, some use a different brake pedal specific to manual or power brakes (the difference being the location of the connection point the master cylinder connects to).

Years ago I did the relocation brackets and drum to front manual disc brake conversion on a customers car. I remember it was a PIA getting the combination figured out as far as pedal ratio, master cylinder and bracket ratio…..did finally end up with a nice system though. Problem is it’s been so long ago I can’t remember even which of his cars we did it on (old age and CRS).

Fortunately, on this car I’m starting with a brake system that works well as is and just relocating the master cylinder for valve cover clearance. I just glanced at the brackets when they came in and I figured I may have to change the ratio on the brackets, which shouldn’t be any more involved than modifying the existing arm from the bracket to the master cylinder (or building a new arm) to move the connection point between the pedal and the bracket pivot higher up. Sounds good on paper anyway LOL.

.

I’m definitely gonna follow this, since I’ve got a Gen I 392 Hemi I want to build and stuff into my 75 Scamp. Mine will either be a full custom or mad max style, so I won’t be limited to the factory inner fenders, but this build will still give me a lot of ideas.

Also, I’m super jealous of your 57!

Also, I’m super jealous of your 57!

Mike P 52

Active Member

“……I’ve got a Gen I 392 Hemi I want to build and stuff into my 75 Scamp. Mine will either be a full custom or mad max style, so I won’t be limited to the factory inner fenders, but this build will still give me a lot of ideas……”

I think you’ll find it an “interesting” project. I know you’re aware of it, but for those that aren’t the Gen 1 392 has a taller deck height than the 331/354 Gen 1 HEMIs. There have been a couple of times I’ve thought I’m glad I’m not doing a 392 (and having to deal with the extra width and height).

That being said the not having to deal with the inner fenders, especially on the passengers’ side will eliminate some of the issues I ran in to. I don’t know, but the extra height and width may even work in your favor when it comes to dealing with the exhaust around the steering box.

The one suggestion I can give you is too keep an eye out for any deals on parts for your 392. I’ve been playing with the Gen 1 HEMIs for a couple of decades now and over the last couple of years I’m finding more and more parts that used to be readily available just not being out there anymore. The basic internal parts you’ll need for a good basic rebuild are still available (pistons, bearings, valves, gaskets, etc). Things like brackets, adapters, a choice of intake manifolds, valve covers etc, seem to be getting scarce. When I built my 354 a couple of years ago it surprised me what was no longer available or on back order (the cam I used was on back order for 6 months). Of course the price on stuff has been hit my inflation like everything else, what seems too high today may look like a bargain a year from now.

I think you’ll find it an “interesting” project. I know you’re aware of it, but for those that aren’t the Gen 1 392 has a taller deck height than the 331/354 Gen 1 HEMIs. There have been a couple of times I’ve thought I’m glad I’m not doing a 392 (and having to deal with the extra width and height).

That being said the not having to deal with the inner fenders, especially on the passengers’ side will eliminate some of the issues I ran in to. I don’t know, but the extra height and width may even work in your favor when it comes to dealing with the exhaust around the steering box.

The one suggestion I can give you is too keep an eye out for any deals on parts for your 392. I’ve been playing with the Gen 1 HEMIs for a couple of decades now and over the last couple of years I’m finding more and more parts that used to be readily available just not being out there anymore. The basic internal parts you’ll need for a good basic rebuild are still available (pistons, bearings, valves, gaskets, etc). Things like brackets, adapters, a choice of intake manifolds, valve covers etc, seem to be getting scarce. When I built my 354 a couple of years ago it surprised me what was no longer available or on back order (the cam I used was on back order for 6 months). Of course the price on stuff has been hit my inflation like everything else, what seems too high today may look like a bargain a year from now.

Want a 331? lol“……I’ve got a Gen I 392 Hemi I want to build and stuff into my 75 Scamp. Mine will either be a full custom or mad max style, so I won’t be limited to the factory inner fenders, but this build will still give me a lot of ideas……”

I think you’ll find it an “interesting” project. I know you’re aware of it, but for those that aren’t the Gen 1 392 has a taller deck height than the 331/354 Gen 1 HEMIs. There have been a couple of times I’ve thought I’m glad I’m not doing a 392 (and having to deal with the extra width and height).

That being said the not having to deal with the inner fenders, especially on the passengers’ side will eliminate some of the issues I ran in to. I don’t know, but the extra height and width may even work in your favor when it comes to dealing with the exhaust around the steering box.

The one suggestion I can give you is too keep an eye out for any deals on parts for your 392. I’ve been playing with the Gen 1 HEMIs for a couple of decades now and over the last couple of years I’m finding more and more parts that used to be readily available just not being out there anymore. The basic internal parts you’ll need for a good basic rebuild are still available (pistons, bearings, valves, gaskets, etc). Things like brackets, adapters, a choice of intake manifolds, valve covers etc, seem to be getting scarce. When I built my 354 a couple of years ago it surprised me what was no longer available or on back order (the cam I used was on back order for 6 months). Of course the price on stuff has been hit my inflation like everything else, what seems too high today may look like a bargain a year from now.

-