BillGrissom

Well-Known Member

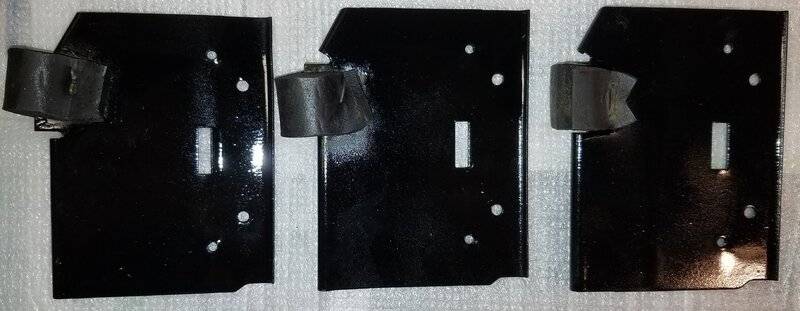

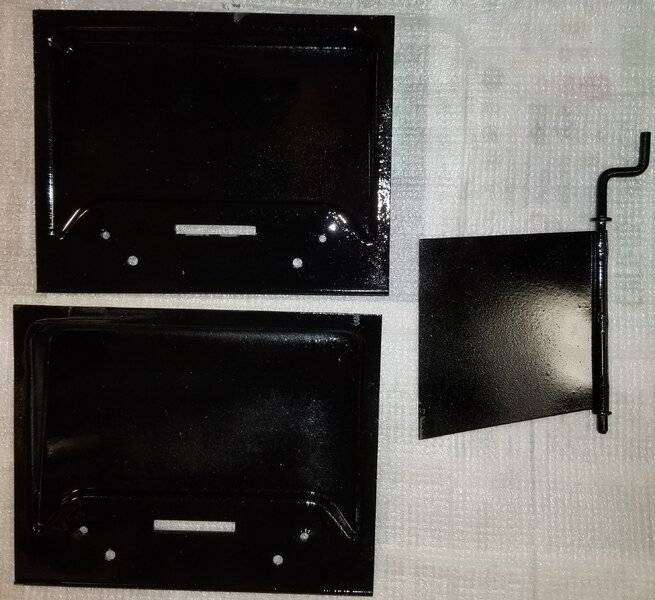

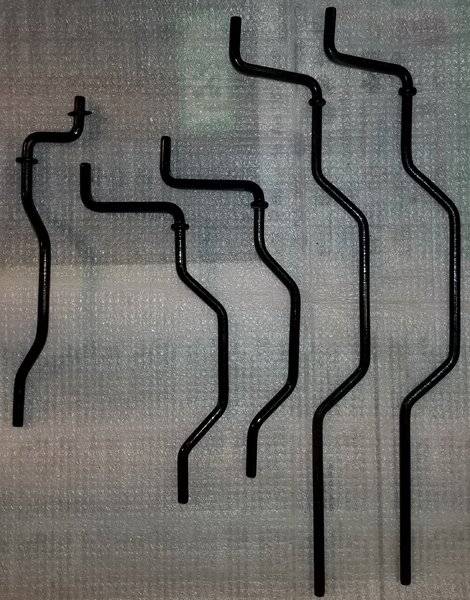

I stripped and restored two 1964 and one 1965 climate boxes (heat only) for my 64 & 65 A's. Actually, the spare might have been 1963 (identical to 1964?), since I recall picking a 1963 A at PicNPull years ago. Photos and notes which might help someone shopping for parts on ebay. In the parts photos, the odd one out is the 1965. The climate doors and locations varied.

I spent much time wire-brushing and sanding off rust, using phosphoric acid, then primed and painted all metal. I repaired the composite housings using fiberglass-epoxy. For the degraded paperboard cover at the rear, I cut new material out of foamboard from JoAnn's Fabrics. I relined the doors with foam, using the white packaging foam in the background. I also took the motors apart and re-lubed inside and painted purty. I tested all the heater cores w/ air pressure (bike pump) under water. Sorry, no photos of the finished boxes.

Labelling:

1964 Heater Box

engine side: W-3 2485254

cabin side: W-3 2 277510

1965 Heater Box

engine side: W-3 2485967

cabin side: Model 734 2, PN 2277510, W 2

Resistors

1964 no numbers

1965 2521409

I spent much time wire-brushing and sanding off rust, using phosphoric acid, then primed and painted all metal. I repaired the composite housings using fiberglass-epoxy. For the degraded paperboard cover at the rear, I cut new material out of foamboard from JoAnn's Fabrics. I relined the doors with foam, using the white packaging foam in the background. I also took the motors apart and re-lubed inside and painted purty. I tested all the heater cores w/ air pressure (bike pump) under water. Sorry, no photos of the finished boxes.

Labelling:

1964 Heater Box

engine side: W-3 2485254

cabin side: W-3 2 277510

1965 Heater Box

engine side: W-3 2485967

cabin side: Model 734 2, PN 2277510, W 2

Resistors

1964 no numbers

1965 2521409

Last edited: