You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1970 Duster project in Sweden

- Thread starter trebor75

- Start date

-

moparmat2000

Well-Known Member

Dang !!! 68 Charger R/T and a 69 Super Bee. I love 66-70 B bodies !!

Things are coming together at my new place. I have started a list on things that needs attention after the engine build/swap. Spring is finally here and I have done some short test drives. Gonna start tuning the engine real soon. I installed an Autometer wideband A/F recently to help me with that.

I have some annoying small problems to deal with first. The thermostat housing leaks and my temp gauge no longer seems to work, I got a small leak at one of the valve covers and also a small leak at the oil filter. I think it's the plate behind the filter that I need to tighten.

I have some annoying small problems to deal with first. The thermostat housing leaks and my temp gauge no longer seems to work, I got a small leak at one of the valve covers and also a small leak at the oil filter. I think it's the plate behind the filter that I need to tighten.

suggest that you get a thermostat gasket from Real Gaskets in Tennessee. I've tried other gaskets of theirs and was underwhelmed but that thermostat gasket is great. If you get one FOLLOW THE INSTRUCTIONS. I have one that I have used in a motor for 3 years and I needed to remove the housing twice. I followed the directions and reused the same gasket and it has never leaked.

Thanks, I will have a look at that. I installed it with a gasket and some rtv, but it still weeps a little when parked.suggest that you get a thermostat gasket from Real Gaskets in Tennessee. I've tried other gaskets of theirs and was underwhelmed but that thermostat gasket is great. If you get one FOLLOW THE INSTRUCTIONS. I have one that I have used in a motor for 3 years and I needed to remove the housing twice. I followed the directions and reused the same gasket and it has never leaked.

moparmat2000

Well-Known Member

Flat surface plate and sandpaper to make sure housing is flat. Use a paper type gasket, and permatex "indian head" gasket shellac. It wont leak.

Thanks. I did the sandpaper and flat surface today, paper gasket and regular rtv was what I had. I think that one of the bolts bottomed out (stupid mistake on my behalf). But that is now fixed. Will let it cure overnight.Flat surface plate and sandpaper to make sure housing is flat. Use a paper type gasket, and permatex "indian head" gasket shellac. It wont leak.

Some photos from todays work. I decided I wanted to try the Edelbrock AVS2 650. Also installed a new water temp gauge and the center caps for my wheels. Done a lot of other stuff too that I can cross off my list  The thermostat housing no longer leaks. Instead I have an annoying drip at one place of the pan the transmission. Tackle that next. Is there a really good pan gasket that I can get? I cant remember whats on there now.

The thermostat housing no longer leaks. Instead I have an annoying drip at one place of the pan the transmission. Tackle that next. Is there a really good pan gasket that I can get? I cant remember whats on there now.

moparmat2000

Well-Known Member

They make pan gaskets out of neoprene rubber. Make sure the pan flange is good and flat at the screw holes. It doesnt take much to snug it up. I bought one that's a deep sump pan for a jeep with an A904 from a jeep offroad site complete with built in drain plug. Heavy gage powdercoated steel. Jeeps also use A727s as well. Comes with neoprene gasket, filter, longer screws and filter extender. I think I payed $50 for it. Price has gone up a bit. It's got a built in drain and is really thick gage steel. RT offroad for A904 or A999

Last edited:

Thanks Mat. My pan is not one of those deep one's, but I have been thinking I should get one of those, so I might just do that. Is it a no, no to put a thin coat of rtv on the pan gasket?They make pan gaskets out of neoprene rubber. Make sure the pan flange is good and flat at the screw holes. It doesnt take much to snug it up. I bought one that's a deep sump pan for a jeep with an A904 from a jeep offroad site complete with built in drain plug. Heavy gage powdercoated steel. Jeeps also use A727s as well. Comes with neoprene gasket, filter, longer screws and filter extender. I think I payed $50 for it. Price has gone up a bit. It's got a built in drain and is really thick gage steel. RT offroad for A904 or A999

View attachment 1716084412

View attachment 1716084413

I’d use RTV. And tighten carefully as not to squeeze the gasket out. On other gaskets like the one piece rubber/steel inside, there are “O” rings of brass/steel around the bolt holes. This can just be torqued to specs and forgotten about. Though some RTV in the corners of the pan are needed.

Thanks. I will probably get one of those gaskets and use some rtv when installing it. I dont remember what gasket is on there now, but I do remember being thorough when installing the pan. It was nice and straight and everything was clean and nice. The leak is at the front of the pan. I can see it so I'm sure it is the pan.I’d use RTV. And tighten carefully as not to squeeze the gasket out. On other gaskets like the one piece rubber/steel inside, there are “O” rings of brass/steel around the bolt holes. This can just be torqued to specs and forgotten about. Though some RTV in the corners of the pan are needed.

if you look up Torqueflite 904 pan gasket up on the Summit Racing web site they offer a pan gasket with a silicone bead around it. I tried one because of a persistant leak and it sealed right up - had to take the pan off again and reused the gasket and it sealed right up again! You use no sealant with this gasket.

Seth Jones

Well-Known Member

What wheel and tire sizes did you use if you don’t mind me asking.View attachment 1715535970

View attachment 1715535969 View attachment 1715535971

Some more progress from today. My new Indy Mags and tires is finally on so I can show the car forward. It was on my old steel wheels that went flat after a while before. This is the farthest this car has rolled in two years haha.

Thanks. I have a 727. I found these on summit: LubeLocker LLT-A727 LubeLocker Transmission Pan Gaskets | Summit Racingif you look up Torqueflite 904 pan gasket up on the Summit Racing web site they offer a pan gasket with a silicone bead around it. I tried one because of a persistant leak and it sealed right up - had to take the pan off again and reused the gasket and it sealed right up again! You use no sealant with this

and: Moroso 93110 Moroso Transmission Pan Gaskets | Summit Racing The moroso one I found here in Sweden too.

Front: U.S. Mags U10115505425 U.S. Mags Indy U101 Polished Wheels | Summit RacingWhat wheel and tire sizes did you use if you don’t mind me asking.

Back: U.S. Mags U10115805445 U.S. Mags Indy U101 Polished Wheels | Summit Racing

Front tires: Cooper Cobra - 215/65-15

Back tires: Cooper Cobra - 275/60-15

The back tire is really close to the springs. I might have to use a spacer there.

moparmat2000

Well-Known Member

A thin coat is ok. Make sure the flanges around the screw holes are good and flat, and don't over tighten. Permatex ultra black is what we used at the Chrysler dealer years ago when I did that type of work. As a matter of fact the FWD Chryslers of that era used a lot of that Permatex "form a gasket" as we called it LOL.Thanks Mat. My pan is not one of those deep one's, but I have been thinking I should get one of those, so I might just do that. Is it a no, no to put a thin coat of rtv on the pan gasket?

Should it not work out for you, which I think it will do fine, double check to see if you can find one of the MoPar reusable trans pan gasket commonly found on the newer OD transmissions.

moparmat2000

Well-Known Member

A518, 46RH, 46RE all use the same pan.

Just deeper than the older pans. ;)

So I have spent time fixing things and crossing things off the to do list. Been driving it a few times too. It feels great.

Now I need to look at the cooling system. I have no shroud, I need one and possible a new radiator. We shall see. When I cruise I'm around 176*, but it creeps up when I idle or drive slow. I was expecting that with no shroud. So I'm either gonna see if I can fabricate one or get a aftermarket one like this. It's for a 22" radiator. Do any of you know what size fan I can have with one of those?

Now I need to look at the cooling system. I have no shroud, I need one and possible a new radiator. We shall see. When I cruise I'm around 176*, but it creeps up when I idle or drive slow. I was expecting that with no shroud. So I'm either gonna see if I can fabricate one or get a aftermarket one like this. It's for a 22" radiator. Do any of you know what size fan I can have with one of those?

moparmat2000

Well-Known Member

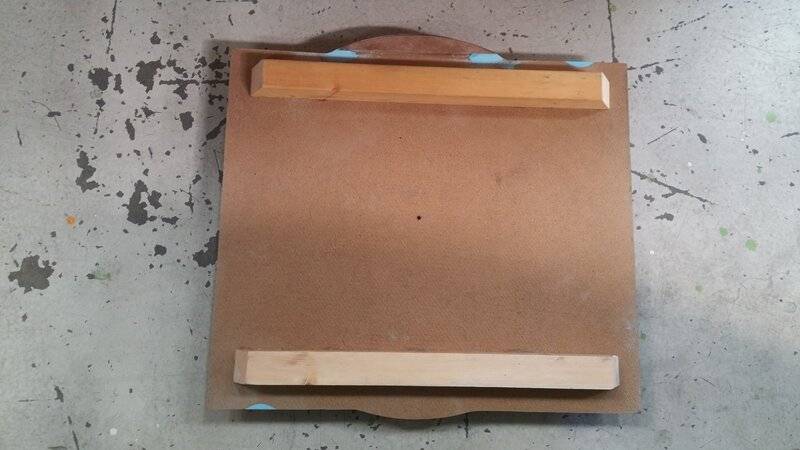

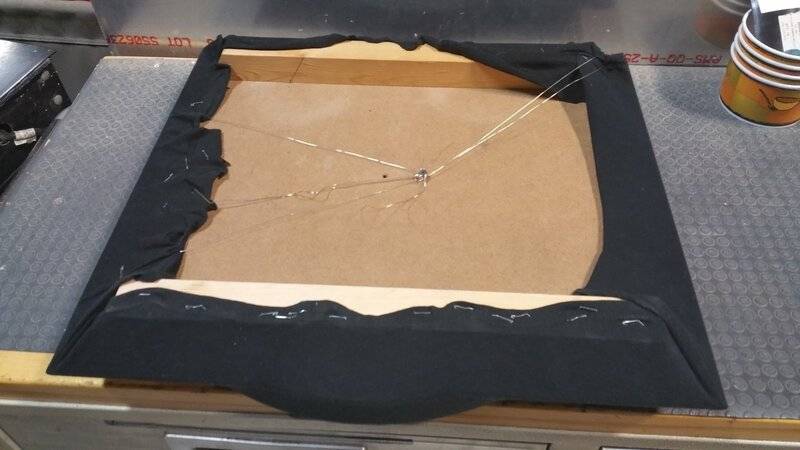

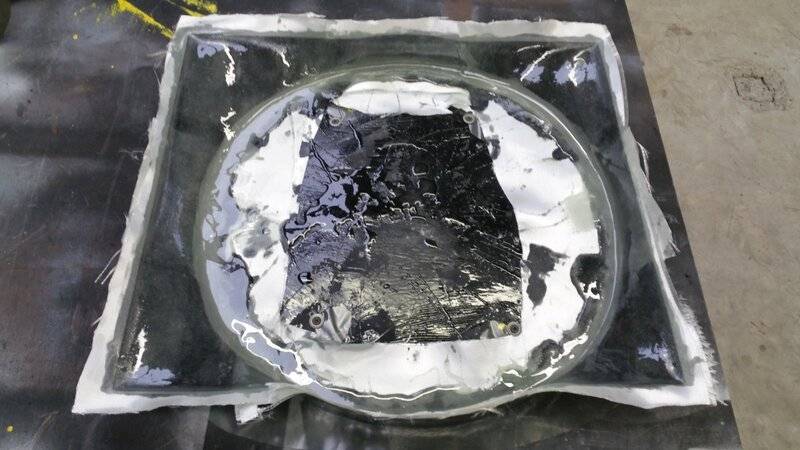

I fabbed one using fiberglass, resin, a homemade buck and an old cotton Tee shirt. I used a peel film on the buck to be able to seperate it. I brushed on 5 layers of resin on the stretched cotton tee shirt. Scuffing between layers of resin as I built it up. This made it stiff enough to pop it from the mould. I screwed it down upside down to plywood, then I wet layed up 2 layers of 7781 fiberglass and resin. 3 layers at the proposed attach points. Then I cut it out and sanded it down. I added reinforcements with JB weld at the top and bottom. Made brackets out of 22 gage steel sheet. These I glued on with JB weld, and used aluminum solid rivets on the fingers. I set it in place and marked where I had to drill the mounting holes. I sprayed it with a few coats of sandable lacquer primer.

Last edited:

moparmat2000

Well-Known Member

More. Note the small radiuses for the radiator hoses. In the previous pix, you can see the build up of JB weld that was carved out for the radiator hoses and tubes to fit the JB weld glue joint on the steel strips is the primary bond joint, the aluminum solid rivets are large head countersink rivets PN# MS20426AD4-(?) rivets. Secondary attachment. The question mark is for length. This rivet is a #4 diameter or #30 drill hole. 100° countersink. I countersunk them slightly deeper than flush to putty over them to hide them. The beauty of this is it can be done for little money compared to a repop, makes for a nice project. Most people would never know the difference anyways

I used an 18" flexalite clutch fan with a 1990 jaguar XJ-6 fan clutch. It's a 22" radiator. You can see just how big this is. I am using a thicker as aluminum radiator so the shorter jag clutch is necessary. My fan blade to shroud spacing is 3/4" from blade to shroud. This allows scavenging, but doesn't let the blades hit from motor torque. I am using a 74 K frame with the round barrel type mounts with polyurethane so there isnt any movement. I'd recommend a torque chain or other engine limiter device.

I used an 18" flexalite clutch fan with a 1990 jaguar XJ-6 fan clutch. It's a 22" radiator. You can see just how big this is. I am using a thicker as aluminum radiator so the shorter jag clutch is necessary. My fan blade to shroud spacing is 3/4" from blade to shroud. This allows scavenging, but doesn't let the blades hit from motor torque. I am using a 74 K frame with the round barrel type mounts with polyurethane so there isnt any movement. I'd recommend a torque chain or other engine limiter device.

Last edited:

Wow! That shroud looks great, thank you for taking the time to share and explain. I was thinking of doing it in thin metal, but this looks like something I might be able to wrap my head around too now that I have this to go by. Awesome!

-

Similar threads

- Replies

- 74

- Views

- 4K

- Replies

- 2

- Views

- 3K

- Locked

- Replies

- 1

- Views

- 7K

- Locked

- Replies

- 9

- Views

- 5K

- Replies

- 11

- Views

- 1K