Working on my console plate , and recovering with black overlay , not perfect but looks good for me , will work more on this tomorrow

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster , starting to tear into the build

- Thread starter 72dustervs

- Start date

-

added scoops to the hood and sanded an prepped hood and getting paint on bottom side and got more primer on firewall , and put some inlay on the console ,,got more black primer to go on firewall then some jet black base coat , and then perhaps will be putting the candy apple color to firewall soon , if weather keeps staying warm

To ensure the quickest service and correct parts, please read carefully through the descriptions below.

TRANSMISSION REBUILD KITS, SYNCHRONIZERS, AND INTERNAL PARTS

Due to numerous internal variations in the A833 4-speed transmission throughout its 23 years of production, identification of certain components is critical in determining the correct rebuild kit, synchronizer stop rings, bearings, etc.

Casting numbers obtained from the:

Front Input Bearing Retainer

(the sleeve bolted to front of the transmission that the throw-out bearing rides on)

Extension Housing (Tailshaft)

will enable us to verify the correct bearings, tailshaft bushing, and seals for your transmission. Casting numbers from the main case DO NOT supply any useful information, as the same cases were machined for both large and small front bearings.

Beginning with the 1968 model year (July 1, 1967), the main case has a small (3" by 7/8") raised, machined rectangular pad on the passenger side of the transmission, just above the casting number. Along with the vehicle's serial number stamped onto it, this pad will have a second line beginning with "PP833" followed by a 4-digit (10,000 day calendar) date code, such as "2264" (10-9-67) or "3055" (12-08-69) and sequential assembly number (405) for that day (pictured). This date code is helpful to us

Beginning with the 1968 model year (July 1, 1967), the main case has a small (3" by 7/8") raised, machined rectangular pad on the passenger side of the transmission, just above the casting number. Along with the vehicle's serial number stamped onto it, this pad will have a second line beginning with "PP833" followed by a 4-digit (10,000 day calendar) date code, such as "2264" (10-9-67) or "3055" (12-08-69) and sequential assembly number (405) for that day (pictured). This date code is helpful to us

in determining what synchronizer stop ring is used, as MOST 1970 and later (2895, 7-1-69) transmissions use the lug-style (SR307) synchronizer stop ring. All 1969 and earlier transmissions (Up to 2894, 6-30-69) used the 3-notch style (SR294) synchronizer stop ring, UNLESS the transmission had been serviced in the early 1970s, and the new style synchronizer assemblies were installed.

in determining what synchronizer stop ring is used, as MOST 1970 and later (2895, 7-1-69) transmissions use the lug-style (SR307) synchronizer stop ring. All 1969 and earlier transmissions (Up to 2894, 6-30-69) used the 3-notch style (SR294) synchronizer stop ring, UNLESS the transmission had been serviced in the early 1970s, and the new style synchronizer assemblies were installed.

As mentioned in the History of the A833 Transmission, many different gear ratios have been used in the Chrysler 4-speed transmission in 23 years. Tooth count on gears help in identification, BUT some gears have the same tooth count even though they are from a different ratio.

One example is the second speed gear from the 2.66- and 2.47-ratio, 23-spline transmissions. Although both have 34 teeth, they are NOT interchangeable. Identification marks (1) on the tips of the 2nd and 3rd speed gear teeth/main drive pinion teeth and (2) between the cluster pinion drive gear/third gear were used to distinguish the different ratios as follows (click photos below to enlarge):

2.44

18-Spline Transmission

Cluster 6 Grooves

Speed Gears 2 Grooves

2.65

18-Spline Transmission

Cluster 2 Grooves

Speed Gears No Grooves

2.47

23-Spline Transmission

Cluster 3 Grooves

Speed Gears 3 Grooves

2.66

23-Spline Transmission

Cluster No Groove

Speed Gears No Groove

3.09

23-Spline Transmission

Cluster One Groove

Speed Gears One Groove

First speed gears carry no identification marks, as the three different 23-spline transmissions utilized the same 1st gear. The two 18-spline ratios also used the same first gear. However, NO gears are interchangeable between 18- and 23-spline transmissions.

This might be a good time to mention that all 18-spline 1st, 2nd, and 3rd-speed gears are bronze bushed. However, not all bushed gears are 18-spline. We have seen some early NASCAR 23-spline transmissions with bushed speed gears as well.

With all this said, please have available the following information before ordering transmission rebuild kits, synchronizer rings, or other internal parts:

With all this said, please have available the following information before ordering transmission rebuild kits, synchronizer rings, or other internal parts:

As in the case of transmission variations, many different flywheels, clutches, bellhousings, clutch forks, clutch linkage geometry, etc. were used in Chrysler Corporation vehicles during the same period. To ensure you get the correct clutch related parts, please have the following information available at time of ordering:

As in the case of transmission variations, many different flywheels, clutches, bellhousings, clutch forks, clutch linkage geometry, etc. were used in Chrysler Corporation vehicles during the same period. To ensure you get the correct clutch related parts, please have the following information available at time of ordering:

All factory (original equipment) Mopar/Hurst 4-speed shifter mechanisms can be identified by the four digit number on the reverse lever, which is the longest of the three. 1968-75 A-body and 1968-69 B-body uses #6353 (as does the later truck overdrive), 1970 B-body #7174, and 1970-74 E-body/1971-74 B-body #7180 (which happens to be stamped upside down). All of these have 5/16" holes for the reverse linkage rod attachment. A common Hurst aftermarket/replacement shifter mechanism (for most A & B applications) has #6370 on the reverse lever, and utilizes a 1/2" hole and a reducer bushing.

The 1963 T10 Borg Warner Hurst mechanism reverse lever is #2041, and the early 1964-65 A & B-body Hurst mechanisms both use #2336 reverse levers, which is stamped on the right side instead of the left. However, the shift handle stubs (where the Hurst handle bolts on) is different on these two mechanisms.

1966 through about January 1968 production, Ma Mopar used an Inland shifter mechanism and shift handles, which are easily identified by the reverse lockout "T" handle, and the unique teardrop shaped shifter knob.

1966 through about January 1968 production, Ma Mopar used an Inland shifter mechanism and shift handles, which are easily identified by the reverse lockout "T" handle, and the unique teardrop shaped shifter knob.

TRANSMISSION REBUILD KITS, SYNCHRONIZERS, AND INTERNAL PARTS

Due to numerous internal variations in the A833 4-speed transmission throughout its 23 years of production, identification of certain components is critical in determining the correct rebuild kit, synchronizer stop rings, bearings, etc.

Casting numbers obtained from the:

Front Input Bearing Retainer

(the sleeve bolted to front of the transmission that the throw-out bearing rides on)

Extension Housing (Tailshaft)

will enable us to verify the correct bearings, tailshaft bushing, and seals for your transmission. Casting numbers from the main case DO NOT supply any useful information, as the same cases were machined for both large and small front bearings.

As mentioned in the History of the A833 Transmission, many different gear ratios have been used in the Chrysler 4-speed transmission in 23 years. Tooth count on gears help in identification, BUT some gears have the same tooth count even though they are from a different ratio.

One example is the second speed gear from the 2.66- and 2.47-ratio, 23-spline transmissions. Although both have 34 teeth, they are NOT interchangeable. Identification marks (1) on the tips of the 2nd and 3rd speed gear teeth/main drive pinion teeth and (2) between the cluster pinion drive gear/third gear were used to distinguish the different ratios as follows (click photos below to enlarge):

2.44

18-Spline Transmission

Cluster 6 Grooves

Speed Gears 2 Grooves

2.65

18-Spline Transmission

Cluster 2 Grooves

Speed Gears No Grooves

2.47

23-Spline Transmission

Cluster 3 Grooves

Speed Gears 3 Grooves

2.66

23-Spline Transmission

Cluster No Groove

Speed Gears No Groove

3.09

23-Spline Transmission

Cluster One Groove

Speed Gears One Groove

First speed gears carry no identification marks, as the three different 23-spline transmissions utilized the same 1st gear. The two 18-spline ratios also used the same first gear. However, NO gears are interchangeable between 18- and 23-spline transmissions.

This might be a good time to mention that all 18-spline 1st, 2nd, and 3rd-speed gears are bronze bushed. However, not all bushed gears are 18-spline. We have seen some early NASCAR 23-spline transmissions with bushed speed gears as well.

- Casting number of front bearing retainer

- Casting number of tailshaft housing

- Style of synchronizer rings (early notch style SR294 or late lug style SR307)

- Gear ratio/tooth count of needed gears

- Date code of transmission

- Ball/detent (1964-70) or interlock (1971-up) style side cover

- Bellhousing casting number (this is found on rear surface of bellhousing where the transmission bolts up)

- Tooth count of flywheel ring gear (generally 130, 143 or 172 teeth)

- Overall length of clutch fork

- Transmission input spline count and casting number of front bearing retainer

All factory (original equipment) Mopar/Hurst 4-speed shifter mechanisms can be identified by the four digit number on the reverse lever, which is the longest of the three. 1968-75 A-body and 1968-69 B-body uses #6353 (as does the later truck overdrive), 1970 B-body #7174, and 1970-74 E-body/1971-74 B-body #7180 (which happens to be stamped upside down). All of these have 5/16" holes for the reverse linkage rod attachment. A common Hurst aftermarket/replacement shifter mechanism (for most A & B applications) has #6370 on the reverse lever, and utilizes a 1/2" hole and a reducer bushing.

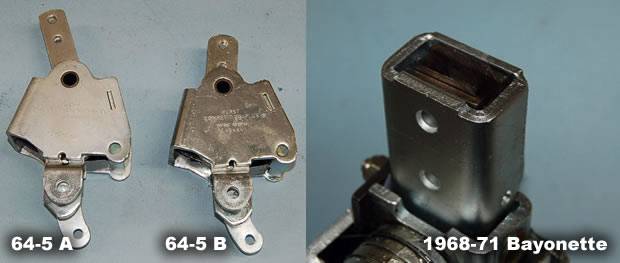

The 1963 T10 Borg Warner Hurst mechanism reverse lever is #2041, and the early 1964-65 A & B-body Hurst mechanisms both use #2336 reverse levers, which is stamped on the right side instead of the left. However, the shift handle stubs (where the Hurst handle bolts on) is different on these two mechanisms.

To ensure the q

SHIFTER MECHANISM IDENTIFICATION

All factory (original equipment) Mopar/Hurst 4-speed shifter mechanisms can be identified by the four digit number on the reverse lever, which is the longest of the three. 1968-75 A-body and 1968-69 B-body uses #6353 (as does the later truck overdrive), 1970 B-body #7174, and 1970-74 E-body/1971-74 B-body #7180 (which happens to be stamped upside down). All of these have 5/16" holes for the reverse linkage rod attachment. A common Hurst aftermarket/replacement shifter mechanism (for most A & B applications) has #6370 on the reverse lever, and utilizes a 1/2" hole and a reducer bushing.

The 1963 T10 Borg Warner Hurst mechanism reverse lever is #2041, and the early 1964-65 A & B-body Hurst mechanisms both use #2336 reverse levers, which is stamped on the right side instead of the left. However, the shift handle stubs (where the Hurst handle bolts on) is different on these two mechanisms.

1966 through about January 1968 production, Ma Mopar used an Inland shifter mechanism and shift handles, which are easily identified by the reverse lockout "T" handle, and the unique teardrop shaped shifter knob.

1966 through about January 1968 production, Ma Mopar used an Inland shifter mechanism and shift handles, which are easily identified by the reverse lockout "T" handle, and the unique teardrop shaped shifter knob.

Two different shift handle attachments have been used on the Hurst mechanisms. The early mechanisms (1963 T10/1964-65) use a solid shift stub that is drilled and tapped for attachment bolts. 1968 introduced the slip-in (or bayonet style) handle attachment, and was used until some early 1971 applications. To remove these handles from the mechanism, a 010" feeler gauge is inserted between the handle and the stainless steel retainer on the driver�s side, which releases the locking tang from the notch in the handle, allowing the handle to be pulled out.

In late 1970, some applications switched to the bolt-on style handle attachment. The first style is similar to the early bolt-on mechanisms, as the threaded anchor is on the stick bottom, and the bolts pass through a small plate to clamp the shift handle into the mechanism. On later bolt-on style mechanisms, the holes are in the stick bottom, and the small plate has the threaded anchors.

Spacing and length of the three levers are unique to each style mechanism.

Brewer's Performance

SHIFTER MECHANISM IDENTIFICATION

All factory (original equipment) Mopar/Hurst 4-speed shifter mechanisms can be identified by the four digit number on the reverse lever, which is the longest of the three. 1968-75 A-body and 1968-69 B-body uses #6353 (as does the later truck overdrive), 1970 B-body #7174, and 1970-74 E-body/1971-74 B-body #7180 (which happens to be stamped upside down). All of these have 5/16" holes for the reverse linkage rod attachment. A common Hurst aftermarket/replacement shifter mechanism (for most A & B applications) has #6370 on the reverse lever, and utilizes a 1/2" hole and a reducer bushing.

The 1963 T10 Borg Warner Hurst mechanism reverse lever is #2041, and the early 1964-65 A & B-body Hurst mechanisms both use #2336 reverse levers, which is stamped on the right side instead of the left. However, the shift handle stubs (where the Hurst handle bolts on) is different on these two mechanisms.

Two different shift handle attachments have been used on the Hurst mechanisms. The early mechanisms (1963 T10/1964-65) use a solid shift stub that is drilled and tapped for attachment bolts. 1968 introduced the slip-in (or bayonet style) handle attachment, and was used until some early 1971 applications. To remove these handles from the mechanism, a 010" feeler gauge is inserted between the handle and the stainless steel retainer on the driver�s side, which releases the locking tang from the notch in the handle, allowing the handle to be pulled out.

In late 1970, some applications switched to the bolt-on style handle attachment. The first style is similar to the early bolt-on mechanisms, as the threaded anchor is on the stick bottom, and the bolts pass through a small plate to clamp the shift handle into the mechanism. On later bolt-on style mechanisms, the holes are in the stick bottom, and the small plate has the threaded anchors.

Spacing and length of the three levers are unique to each style mechanism.

Brewer's Performance

Finally some color , no clear coat yet but like the color , picture not the clearest but make my painting look good lol as I aint no painter

hard to tell in my shop the true color but in the sun it should look great , did shoot one coat of clear

need more light to see but I like it

2nd coat of clear

spchallenger340

Member

Can't help but noticed all the hard work you have been doing on your Duster great job so farOrdered the ESPO springs an shackles an bushings an everything needed , got 5% off since there on back order for around 2 months but hey it aint going to be ready by then anyways

spchallenger340

Member

Have to ask did you ever get rid of those extra ECU boxes you had ??Working on my console plate , and recovering with black overlay , not perfect but looks good for me , will work more on this tomorrow

View attachment 1716052101

yeah couldn't make a deal fast enough for those , everybody wanted themHave to ask did you ever get rid of those extra ECU boxes you had ??

spchallenger340

Member

Never did hear anything back on them so never hurts to ask ... just encase ... Thanks

Got new wing mounted ,

getting motor ready to put in , waiting on the correct clutch fork to put tranny on to motor , will be installing from bottom

KCBones

Well-Known Member

That looks like the best way to put an engine in an old Mopar. It seems to make sense, especially in projects like mine, where the k-member and entire front suspension had to come out anyway.

I will be able to roll it under and lower car down,,may have to raise engine some but should be easyThat looks like the best way to put an engine in an old Mopar. It seems to make sense, especially in projects like mine, where the k-member and entire front suspension had to come out anyway.

closer and only way to install engine an tranny , would have had it in but stripped tranny bolt to bell housing , doh ,,got it re-taped to next size but need a bolt

Decided not to use headers on this build , I love TTI Headers but price these days is a bit much , so the manifolds I am trying out the por-15 high temp paint , its like a stain and is suppose to soak in when heat opens up the cast , so far paint for exhaust looks good , , the reviews say it may need more coats after running but its super thin like stain so it may surprise an do good . Still need to to tap the bottom hole tranny to bell housing , got the top hole repaired but then the bottom on one side just didn't like to tighten , so its a little more difficult short of separating again so we will see , maybe this weekend get motor bolted in to car again

Trying to hold off another week or 2 for my firm feel steering box to get shipped before installing all this , sucks having to wait

Starting to add things instead of removing is always a plus , new master cylinder from Dr. Diff. , new stainless brake lines an few other things installed , firewall pads inside and getting ready for the heater/a/c box

Keep up the good work!

Small progress , got a/c heater box in , started cleaning up fenders and doors , doors pretty solid , pitting at bottom but cleaned up good and worst spots on door , got to rebuild lower hinges at least , top not to bad , fenders , got to fab up upper lip for bolt holes , but I can fix that , and will need lower patches on bottom of fender , but beats buying new I guess

Got the rusted area on upper fender area were it bolts on all cut out , repair looks ok ,now waiting on the lower patch panels to arrive

I feel fortunate I didn't have rust in the areas your working. But then again mine was in the usual exterior spots that yours appears to be missing. Great work keep going.Got the rusted area on upper fender area were it bolts on all cut out , repair looks ok ,now waiting on the lower patch panels to arrive

View attachment 1716094798

View attachment 1716094799

View attachment 1716094800

View attachment 1716094801

Was unusual , and the inner fender was undamaged , unsure if something was spilled an caused this rust or what happened ,I feel fortunate I didn't have rust in the areas your working. But then again mine was in the usual exterior spots that yours appears to be missing. Great work keep going.

-

Similar threads

- Replies

- 0

- Views

- 75

- Replies

- 0

- Views

- 76

- Locked

- Replies

- 11

- Views

- 2K

- Replies

- 7

- Views

- 183

- Locked

- Replies

- 0

- Views

- 148