glhx

Well-Known Member

When this distributor came to me. It came with the cap facting the front of the engine

It occurred to me just a few minutes ago that I have never seen a cap set up like that on a gm. I didn’t catch it.

When I looked at the distributor housing. It has a notch for two cap placements. One to the front and one to the side. I’ve never seen one like this....if I did I didn’t know it.

When I turned the cap to the drivers side.....rotating it 90° the mark went to the left about 1/8”. I think that would put it back into phase.

Now that I have repahsed the reluctor....I don’t know for sure. ....

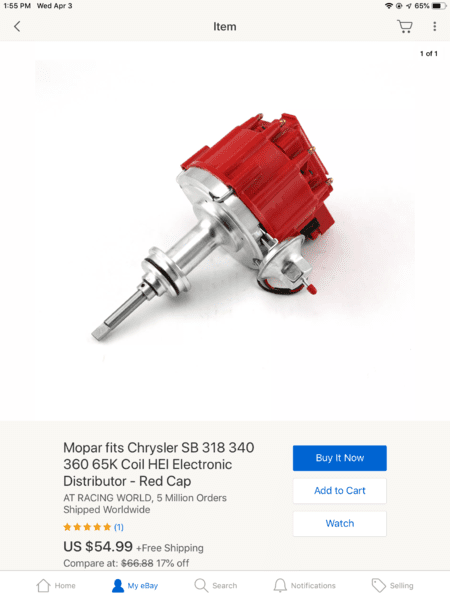

But logic would dictate this is correct. I think this was out of phase because the cap was set the wrong way....and it did come that way. The top picture shows how it was sold to me.

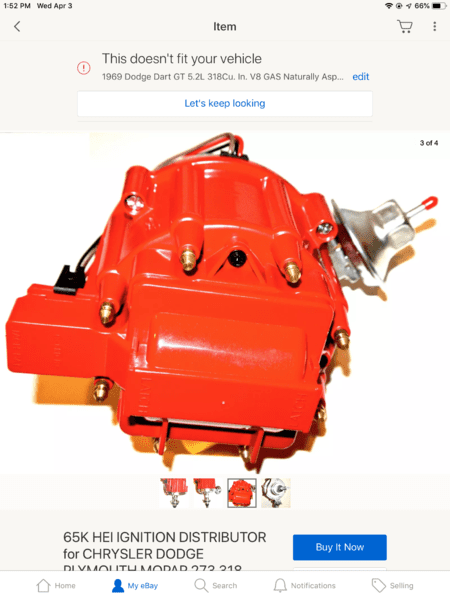

This picture shows how it should be

This is the new mark.....the thin line.

The old mark where I had the cap facing the wrong way is the thick mark

This shows the two notches for the different cap placement. The upper one is with the cap placed forward toward the front of the car......the bottom one is true TDC.

The new thin line is closer to the middle and is not drawn in here

Looking at it with the sideways cap placement. It’s still would be out of phase. Just not as bad.

Instead of relocating the vaccum advance. I could have extended the notch in the distributor housing and rotated the cap.

What would this movement have changed. It might not be backfiring because it would be closer to the #1 than the #8.

But it would still have pretty far for the spark to travel.

Looking at the previous pictures where it was original before I messed with it. Those pictures might tell. It might put it on the leading edge of the points or might even put them in contact.......not really sure.i think this might have been the problem all along.

Thoughts on this?

It occurred to me just a few minutes ago that I have never seen a cap set up like that on a gm. I didn’t catch it.

When I looked at the distributor housing. It has a notch for two cap placements. One to the front and one to the side. I’ve never seen one like this....if I did I didn’t know it.

When I turned the cap to the drivers side.....rotating it 90° the mark went to the left about 1/8”. I think that would put it back into phase.

Now that I have repahsed the reluctor....I don’t know for sure. ....

But logic would dictate this is correct. I think this was out of phase because the cap was set the wrong way....and it did come that way. The top picture shows how it was sold to me.

This picture shows how it should be

This is the new mark.....the thin line.

The old mark where I had the cap facing the wrong way is the thick mark

This shows the two notches for the different cap placement. The upper one is with the cap placed forward toward the front of the car......the bottom one is true TDC.

The new thin line is closer to the middle and is not drawn in here

Looking at it with the sideways cap placement. It’s still would be out of phase. Just not as bad.

Instead of relocating the vaccum advance. I could have extended the notch in the distributor housing and rotated the cap.

What would this movement have changed. It might not be backfiring because it would be closer to the #1 than the #8.

But it would still have pretty far for the spark to travel.

Looking at the previous pictures where it was original before I messed with it. Those pictures might tell. It might put it on the leading edge of the points or might even put them in contact.......not really sure.i think this might have been the problem all along.

Thoughts on this?

Last edited: