Hello everyone, I have been looking for information regarding the pushing of SBM limits with boost on a few other forums, seems to be more boosted guys here than anywhere else.

I am getting close to finishing up a build on my 70 challenger and I was hoping to get some input on the build, mainly looking for advice on how far I should be trying to push it power/boost wise bearing in mind it is mostly a street car that sees track time a few days a year. Here is the build...

1970 340 block, bored .030 over, Hughes stud girdle/ARP main studs, factory forged crank, Eagle H beam rods w/ ARP2000 bolts. I had Speed Pro forged pistons in the motor before, my machinist took a little bit off the top and milled a relief into them to get my C/R down to around 9:2. He told me they still have plenty meat and will hold up fine to boost. All machine work and rotating assembly was done by a machinist I know who does great work, holds a few Pro Stock records and has a stellar reputation for big HP builds so I am confident there.

W2 early LA exhaust pattern 'econo' heads flowing 295cfm at .600, ARP head studs, cometic gaskets, Mopar Performance rocker arms, Solid roller at .609 lift 242/[email protected] 112LSA, ported Indy intake

pump E85 fed via A1000 pump/voltage controller- 12AN to pump, 10AN to FPR, dual 6AN to T/B, 8AN return.

FItech 1200 EFI

MSD 6AL with locked out TSP distributor, going to have FItech control timing

1 7/8ths TTI headers, either a 3" round or 3.5" oval exhaust

eBay special CSX 31x12x3 front mount intercooler, 3" piping

eBay special 3 core aluminum radiator, FlowKooler water pump

Rad came with dual china-fans. May swap out for one high quality fan or try my luck with a mechanical fan

GM 140amp TuffStuff 1 wire mounted on D/side (i'll be finished welding the brackets next week)

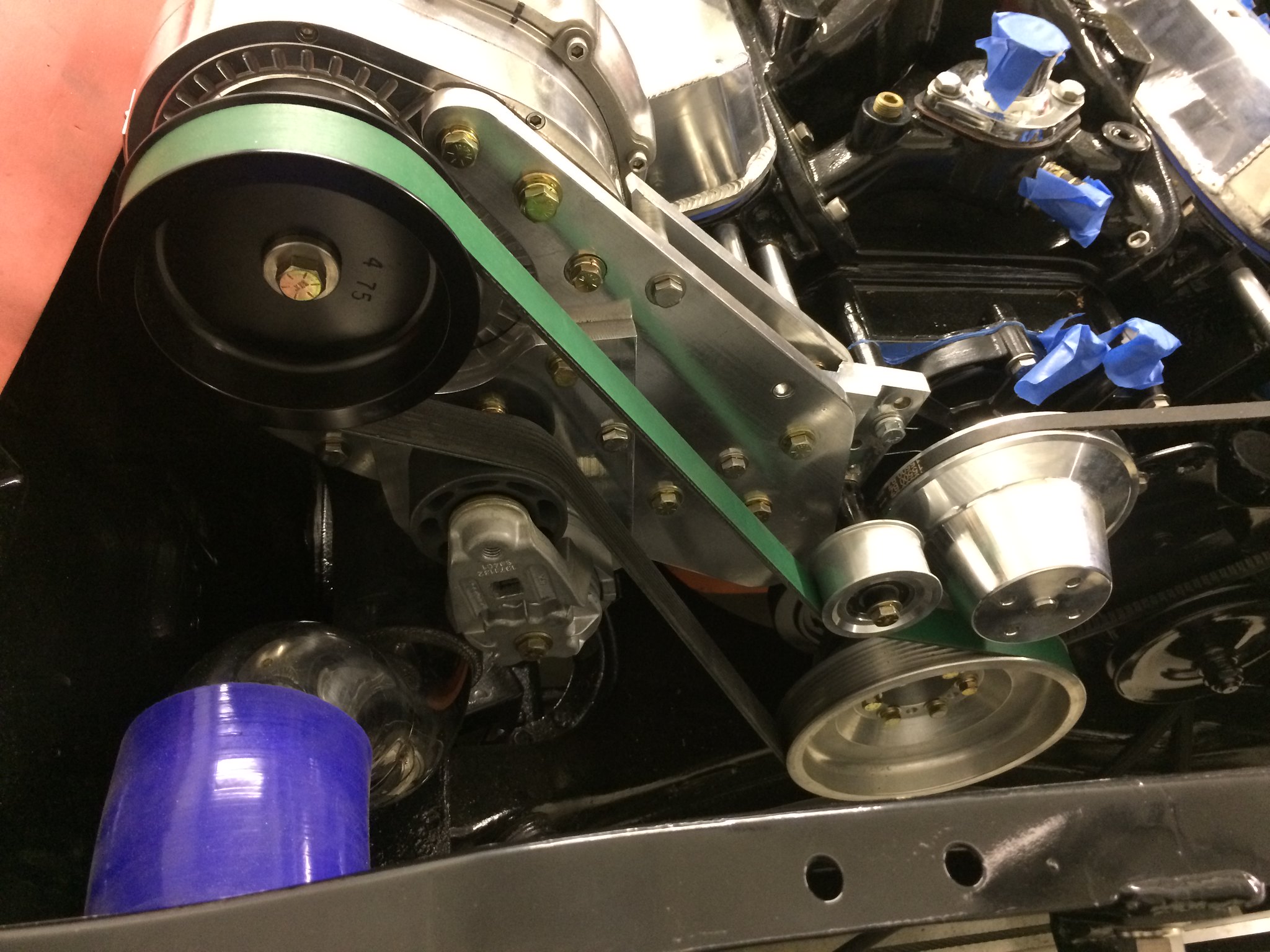

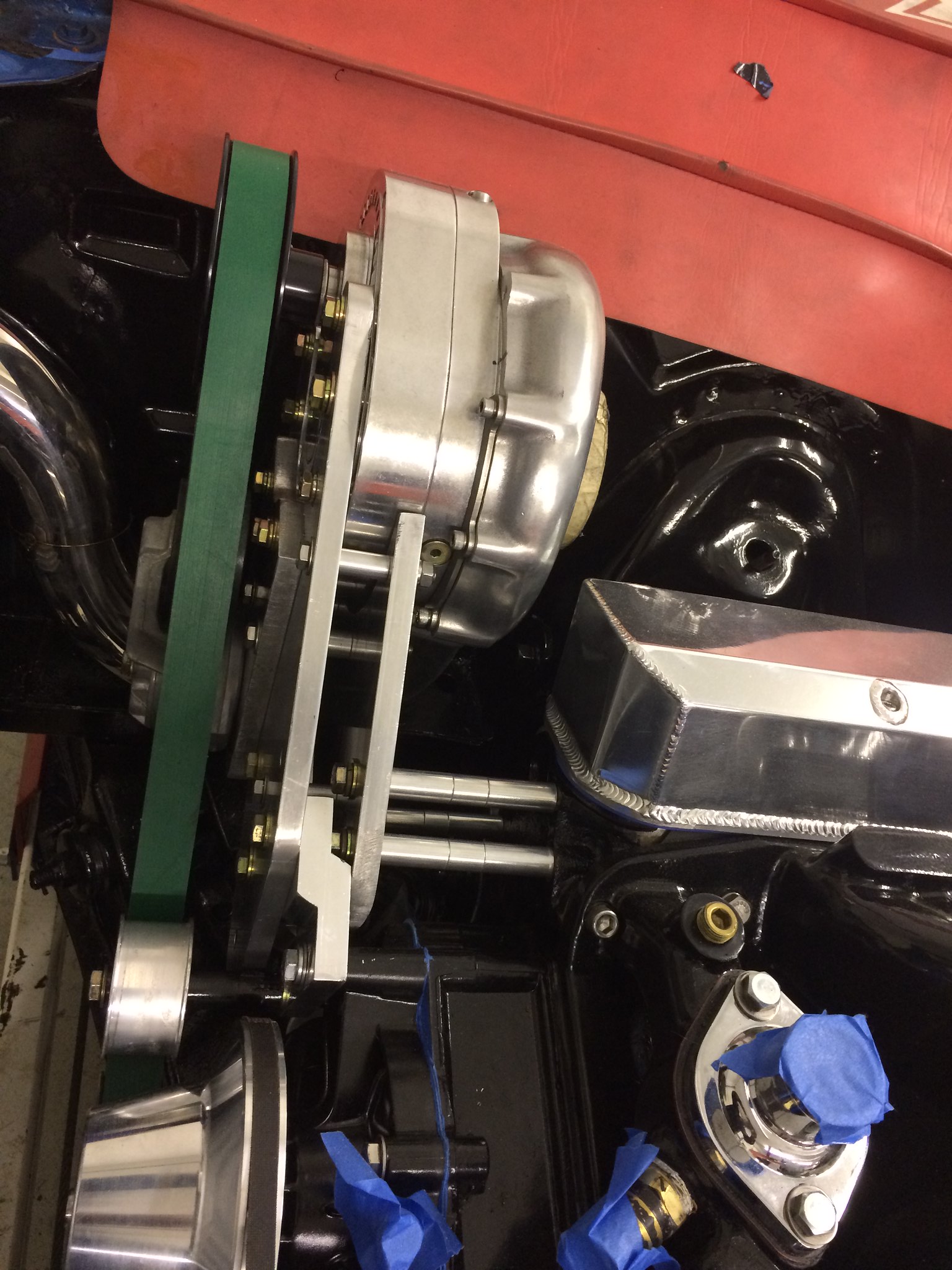

Air fed via D1SC procharger. Found a main bracket on moparts, modified it and built my own rear bracket for it. Using my own custom Dayco tensioner setup, 8 rib. Mondo BOV. SDCE billet crank pulley mounted to an SFI balancer, unknown brand. Procharger low profile carb hat (yes, I know this will cost me some HP, can't fit anything else...yet anyway).

built 727 w/ manual valve body, Protorque 9" converter, 8 3/4 rear with 3.91's/1350 yoke, front mounted trans cooler.

Here are some pics of the progress. I'll get more up of the blower and alternator bracket assembly once I finish it up next weekend.

Car has power steering and brakes. Only lightening done is Weld wheels. I plan to run 12-14 PSI, somewhere in that neighborhood. DOn't really know what kind of power to expect, but I would LOVE if I could hit the high 600's-low 700's without worrying about cracking the block. Low 700's would probably be about the safe limit of my fuel system/EFI setup on E85.

I am getting close to finishing up a build on my 70 challenger and I was hoping to get some input on the build, mainly looking for advice on how far I should be trying to push it power/boost wise bearing in mind it is mostly a street car that sees track time a few days a year. Here is the build...

1970 340 block, bored .030 over, Hughes stud girdle/ARP main studs, factory forged crank, Eagle H beam rods w/ ARP2000 bolts. I had Speed Pro forged pistons in the motor before, my machinist took a little bit off the top and milled a relief into them to get my C/R down to around 9:2. He told me they still have plenty meat and will hold up fine to boost. All machine work and rotating assembly was done by a machinist I know who does great work, holds a few Pro Stock records and has a stellar reputation for big HP builds so I am confident there.

W2 early LA exhaust pattern 'econo' heads flowing 295cfm at .600, ARP head studs, cometic gaskets, Mopar Performance rocker arms, Solid roller at .609 lift 242/[email protected] 112LSA, ported Indy intake

pump E85 fed via A1000 pump/voltage controller- 12AN to pump, 10AN to FPR, dual 6AN to T/B, 8AN return.

FItech 1200 EFI

MSD 6AL with locked out TSP distributor, going to have FItech control timing

1 7/8ths TTI headers, either a 3" round or 3.5" oval exhaust

eBay special CSX 31x12x3 front mount intercooler, 3" piping

eBay special 3 core aluminum radiator, FlowKooler water pump

Rad came with dual china-fans. May swap out for one high quality fan or try my luck with a mechanical fan

GM 140amp TuffStuff 1 wire mounted on D/side (i'll be finished welding the brackets next week)

Air fed via D1SC procharger. Found a main bracket on moparts, modified it and built my own rear bracket for it. Using my own custom Dayco tensioner setup, 8 rib. Mondo BOV. SDCE billet crank pulley mounted to an SFI balancer, unknown brand. Procharger low profile carb hat (yes, I know this will cost me some HP, can't fit anything else...yet anyway).

built 727 w/ manual valve body, Protorque 9" converter, 8 3/4 rear with 3.91's/1350 yoke, front mounted trans cooler.

Here are some pics of the progress. I'll get more up of the blower and alternator bracket assembly once I finish it up next weekend.

Car has power steering and brakes. Only lightening done is Weld wheels. I plan to run 12-14 PSI, somewhere in that neighborhood. DOn't really know what kind of power to expect, but I would LOVE if I could hit the high 600's-low 700's without worrying about cracking the block. Low 700's would probably be about the safe limit of my fuel system/EFI setup on E85.

Last edited: