That may have to wait for the mechanic then, the trans cooler is plumbed into the rad and it seems likely to break the fittings, the one on the driver side is bent, but not leaking.Got to get a spacer on that fan to get it to within 3/4" of the radiator. Then it will pull air through the radiator and cool it down without the shroud.

Yes you have to pull the radiator to get the Fan and Spacer in there first, then re-install the radiator.

Knew there was something wrong with your installation when you said it would not cool with the mechanical fan.

☆☆☆☆☆

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

451 overheating, even when moving

- Thread starter canajien

- Start date

-

That may have to wait for the mechanic then, the trans cooler is plumbed into the rad and it seems likely to break the fittings, the one on the driver side is bent, but not leaking.

You can cut the transmission line below the fan with a small tubing cutter.

Then you can pull the radiator, install the fan and spacer.

When the radiator is back in use a 2" length rubber transmission hose and 2 band clamps to secure it on the transmission Cooler line splice.

☆☆☆☆☆

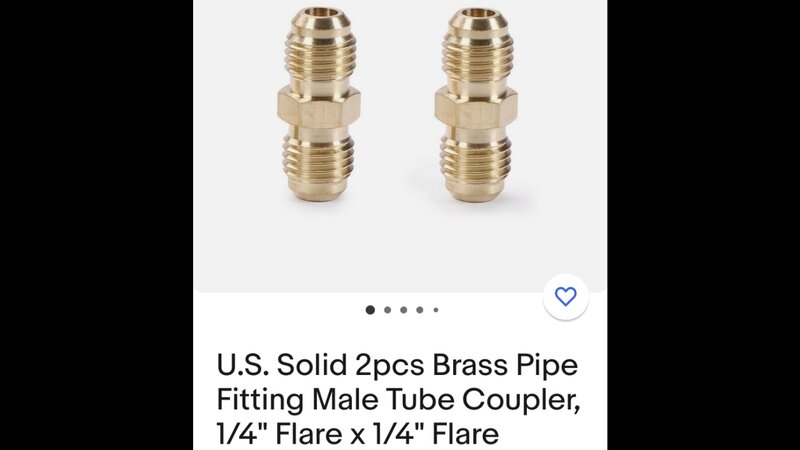

These work too to splice the cooler lines. Will need some flaring tools and the flare nuts.

Then you can get new stub lines put in that come out of the radiator, for the ones that are twisted and bent now.

Your choice

☆☆☆☆☆

Then you can get new stub lines put in that come out of the radiator, for the ones that are twisted and bent now.

Your choice

☆☆☆☆☆

The wierd thing is, there seems to be one line coming out of the rad, into a seperate cooler into the front of the rad and then back to the trans...If you really want to improve the cooling:

- use a shroud, which will pull cooling air through all of the core, not some of it....

- use a separate trans cooler.

Things can be complicated.

As now you have an already taxed cooling system setup that is also setup to flow hot automatic transmission fluid through the bottom of the radiator first then on to the external transmission cooler.

You might ask how was the High Performance 440 in post #12 able to run cool with the 18" solid mount fan and no shroud.

One part of the successful setup was that it was a factory manual 4 speed car, so no hot transmission fluid was being pumped into the radiator.

Just one more piece of the puzzle that an independent external transmission fluid cooler may be a good idea as Bewy states above. Bypassing the need to run hot transmission fluid through the radiator, and that much less heat that you will be having to pull out of your cooling system.

☆☆☆☆☆

As now you have an already taxed cooling system setup that is also setup to flow hot automatic transmission fluid through the bottom of the radiator first then on to the external transmission cooler.

You might ask how was the High Performance 440 in post #12 able to run cool with the 18" solid mount fan and no shroud.

One part of the successful setup was that it was a factory manual 4 speed car, so no hot transmission fluid was being pumped into the radiator.

Just one more piece of the puzzle that an independent external transmission fluid cooler may be a good idea as Bewy states above. Bypassing the need to run hot transmission fluid through the radiator, and that much less heat that you will be having to pull out of your cooling system.

☆☆☆☆☆

I'm going to try and get it up on axle stands today to confirm that what I see from above corresponds to this, I'm pretty sure it's running through the rad and then the external cooler...Things can be complicated.

As now you have an already taxed cooling system setup that is also setup to flow hot automatic transmission fluid through the bottom of the radiator first then on to the external transmission cooler.

You might ask how was the High Performance 440 in post #12 able to run cool with the 18" solid mount fan and no shroud.

One part of the successful setup was that it was a factory manual 4 speed car, so no hot transmission fluid was being pumped into the radiator.

Just one more piece of the puzzle that an independent external transmission fluid cooler may be a good idea as Bewy states above. Bypassing the need to run hot transmission fluid through the radiator, and that much less heat that you will be having to pull out of your cooling system.

☆☆☆☆☆

Should have had a better look when it was at the other mechanics getting a safety

The lines were both for the transmission so I clamped them and removed them from the rad, I'll splice them together with a barbed fitting. Out from the trans, into the rad, out from the rad, into the cooler, then back out to the trans.

I repurposed the original shroud to mount the pusher fan, just need to wait for the spacer to show up and I'll put it back together.

Will a 3/8 plug close those holes in the bottom of the rad?

I repurposed the original shroud to mount the pusher fan, just need to wait for the spacer to show up and I'll put it back together.

Will a 3/8 plug close those holes in the bottom of the rad?

Last edited:

Why block the transmission cooler ports in the radiator?The lines were both for the transmission so I clamped them and removed them from the rad, I'll splice them together with a barbed fitting. Out from the trans, into the rad, out from the rad, into the cooler, then back out to the trans.

I repurposed the original shroud to mount the pusher fan, just need to wait for the spacer to show up and I'll put it back together.

View attachment 1716115803

Will a 3/8 plug close those holes in the bottom of the rad?

Keep crud from getting into it?Why block the transmission cooler ports in the radiator?

Or is it beneficial to leave them open?

Why wouldn't you USE the cooler in the radiator?Keep crud from getting into it?

Or is it beneficial to leave them open?

See post #81Why wouldn't you USE the cooler in the radiator?

I respectfully disagree with not using the cooler in the transmission. If you have to eliminate "THAT" in order to help it run cooler, something is wrong. They just don't make that big a difference in cooling system temps.See post #81

Yeah I get that. You're supposed to use both if you have the cooler in the radiator. Carry on.The trans already has a standalone cooler

It was running through the rad first, then the trans own cooler then back to the trans

Noted, but it should push at least 1200 or 1300 CFM. If it doesn't work then it's easy enough to remove. It will pretty much be the same setup as a guy I met last week who was overheating his 440, efan pushing, mechanical fan pulling, he can now drive around with no worries.Looks like instead of blocking the backside of the radiator you’re simply blocking the frontside now. Albeit not as much. I’d repurpose that aluminum to the cutoffs and scraps box.

View attachment 1716115858

I'm more worried about the trans cooler which pretty much sits in front of the entire drivers side of the rad, if rad starts cooling enough I can try running the trans back through the rad, with no external cooler.

I'll be swapping the 3.91s in the rear for some 3.23s soon as well, it's not a drag car anymore, but it should still do nice burnouts.

The previous owner can't tell me what this thing is running for compression, so it's entirely possible he was just optimistic about it being driven to the city without problems as he lives out in the country.

After 50 odd years no two of these are the same anymore, all I can do is take the helpful advice here and apply it till something works. It's not urgent, I've got the time to sort it out, I'm actually enjoying this process. Besides I got this for a daily driver/drag car.

TT5.9mag

Two atmospheres are better than one

Just curious, grab the distributor and see if it’s loose, 950-1000 degree header primary tubes, while idling is way too hot and I suspect very retarded initial timing. Do you know what the initial timing is?

I can only guess it has to do with idle? Please fill in my blanks!Just curious, grab the distributor and see if it’s loose, 950-1000 degree header primary tubes, while idling is way too hot and I suspect very retarded initial timing. Do you know what the initial timing is?

I'll check the distributor either later tonight or tomorrow morning.

OK, ordered one. I was gonna get one of the guys to show me this weekend, but the commie flu put an end to that. May as well learn for myself, hopefully the timing marks are still there.Low initial timing starts the fire late and puts a lot of heat into the exhaust. And the coolant. Get a timing gun and see where it’s at.

TT5.9mag

Two atmospheres are better than one

It’s easy, clamp inductive pick up lead to number one spark plug wire as close to the plug as possible. Hook up clamps to battery pos and neg. Start engine, pull trigger, point gun at damper where the timing tab is. Shade and or dark garage helps.

Edited to add:

Also coloring the timing mark on the balancer with chalk or white marker helps.

Edited to add:

Also coloring the timing mark on the balancer with chalk or white marker helps.

Last edited:

The distributor is quite solid, no movement at all.I can only guess it has to do with idle? Please fill in my blanks!

I'll check the distributor either later tonight or tomorrow morning.

The spacer came, hooray!!!

The bolts are the wrong thread, boooooooooooo

Will 5/16 x 18 x 2 1/2 fit to hold the fan in the water pump? I have to order these things... Coz of commie flu

Good Deal

Send someone into your local Ace Hardware store to get the bolts, grade 5 they will have them, flat washers and lock washers too.

☆☆☆☆☆

-

Similar threads

- Replies

- 36

- Views

- 2K

- Replies

- 5

- Views

- 5K