MidnightSwinger

Well-Known Member

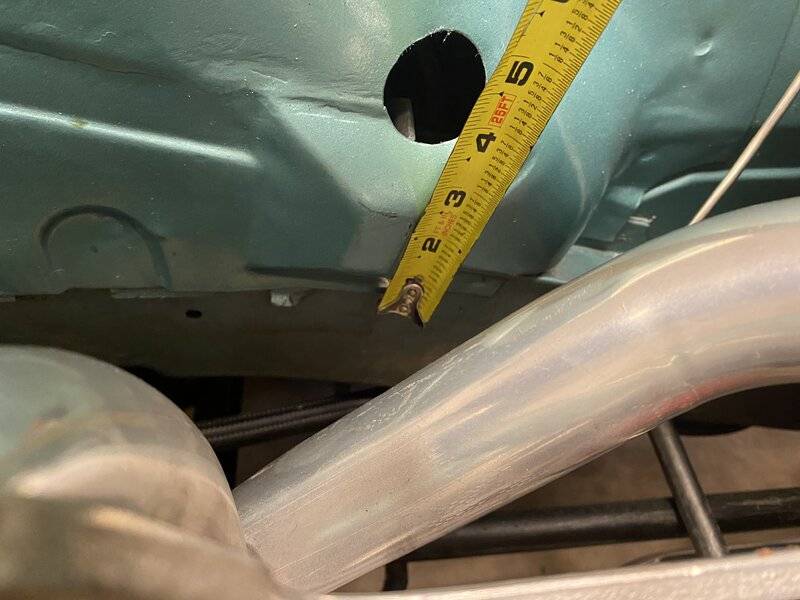

Can anyone share some measurements? I want to get the hole cut before I paint the engine bay. I have a 1 3/4” hole saw and a buddy of mine sent me these pics for reference. How does it look? I don’t have the ability to install the engine first so I am going to get it as close as poss. Any help or input always appreciated.

Jared

Jared