moparmat2000

Well-Known Member

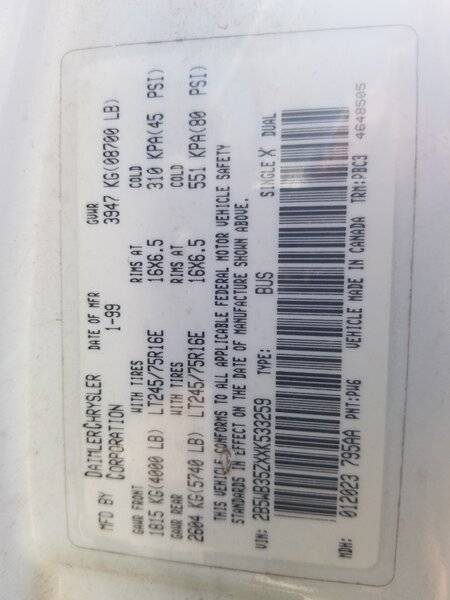

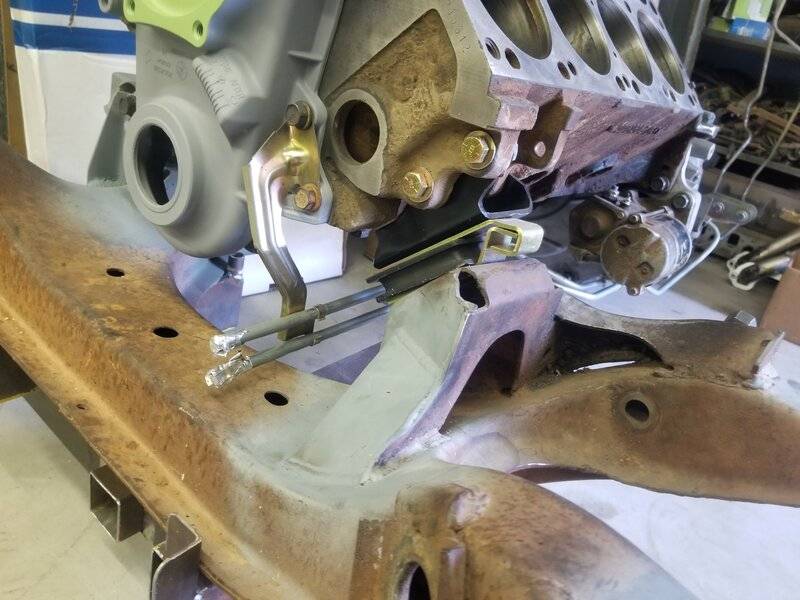

I have a set of 1992 dakota V8 lines but they route up high on the block instead of along the oil pan. They just sit really wrong looking for me. So I went on a junkyard hunt today. A 1999 Ram B350 van gave up its transmission lines. I plan on using AN-6 fittings and braded line at the front going to the trans fluid thermostat. Then I will run hard line from there to the front mounted cooler. After I cleaned em up and blew em out with alcohol and compressed air I mocked them up. The rear one just about fell into place. The FWD line needed a little more careful tweaking to fit at the transmission end. I went with the 99 model van because at the front on this van, the one line doesnt make a hard 90° right turn under the balancer, and I needed them to come out for the most part straight at the front. I even grabbed the dandy line mounting brackets. 5th pic shows them with the stock bends in the front. The last pic you can see where I straightened the tubes and cut them even. Finding a set of almost straight bolt in lines was bothering me. I'm pretty happy i found what I did, and with the results. Heres pix.

Last edited: