Also... during this time... the virus blew up AND we had to say goodby to our old girl, Bella (12 years old)... we still have her amazing nephew Koda (10 years now... pictured laying on her when he was a puppy) so many challenging days...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

69 Notch Barracuda - Rebirth

- Thread starter JAndrea

- Start date

-

Eventually the plan is to paint it, but I’m going to drive it “mean and greasy” for a few years. I love this look.When you get it all sorted, are you going to take it all back apart for paint? I love that 69 sunfire yellow. I plan on using that on my 67 notch.

moparmat2000

Well-Known Member

It looks good with that stance and the black steelies with chrome lug nuts. We are heading that direction on my sons 69 notchback.

moparmat2000

Well-Known Member

Sorry to hear about your pupper. Our old girl is 18. Her time is drawing near as well.

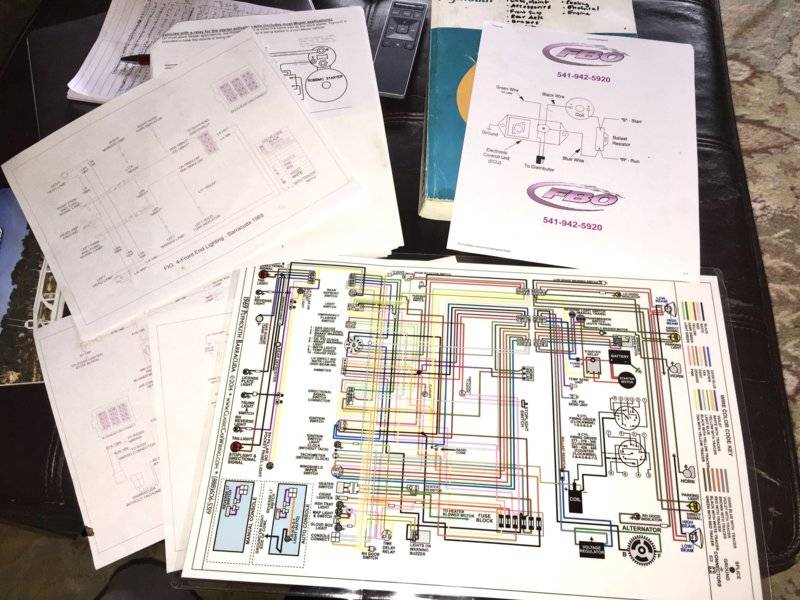

So... electrical... I let the JBWeld harden on the clip, and plugged it in... LIGHTS!!!

I then cleaned all of the connections and wires, and then the actual component... of what I came to know as the “starter relay”. I connected my test light to the end of the starter solenoid wire, then to the negative post on the battery and turned the ignition key. Nothing.

Here is the happy-ending troubleshooting thread to this mystery. (The pic below is before cleaning)

I then cleaned all of the connections and wires, and then the actual component... of what I came to know as the “starter relay”. I connected my test light to the end of the starter solenoid wire, then to the negative post on the battery and turned the ignition key. Nothing.

Here is the happy-ending troubleshooting thread to this mystery. (The pic below is before cleaning)

Thank you. They are such a huge part of the family. Good luck to you.Sorry to hear about your pupper. Our old girl is 18. Her time is drawing near as well.

I’ve also pulled the old regulator and installed a new electronic style regulator (based on FABO advice/readings). For now, I’m keeping the original ballast resistor (until it is proven to not work... as of now, I’m thinking it will work, but will test it)... also in the process of wiring my new ECU to the coil and BR and have one last splice ECU connection to make (to the “Run” wire). I’m basically tracing out all the wires, matching an indicator light to switch behavior, and trying NOT to do any guess work, which I think is a dangerous way to go about any electrical work... and a great way to NOT learn about your car.

Definitely finding some brittle wire casings, so being very careful. I’ve really only had to modify one existing wire... which was the coil wire. On a 318 (original motor) the coil is at the back of the compartment. I just made sure I used the correct gauge and color wire, as stated in the diagram, and run some new length and connections to the coil. Incidentally, my electrical connection supplies come from Vintage Connections (first utilized during my motorcycle wiring project). This guy sells great stuff.

Definitely finding some brittle wire casings, so being very careful. I’ve really only had to modify one existing wire... which was the coil wire. On a 318 (original motor) the coil is at the back of the compartment. I just made sure I used the correct gauge and color wire, as stated in the diagram, and run some new length and connections to the coil. Incidentally, my electrical connection supplies come from Vintage Connections (first utilized during my motorcycle wiring project). This guy sells great stuff.

Last edited:

Resources...

moparmat2000

Well-Known Member

YearOne puts the wiring harnesses on sale periodically. The firewall forward harness can be had for about $150 and is worth it to not deal with brittle wiring and corrosion in the connectors.

Yeah... I’ve been keeping an eye on that harness. Seems WELL worth the $. I’m sure I’ll get it, but for now, I’m still able to move forward.YearOne puts the wiring harnesses on sale periodically. The firewall forward harness can be had for about $150 and is worth it to not deal with brittle wiring and corrosion in the connectors.

Did a lot of test light confirming on the starter solenoid wire when turning the key, electronic ignition box, coil, ballast resistor (~9v at coil), etc... but decided I HAD to actually test/turn her over today with the RobbMC starter before installing the drivers side TTi header. The TTi instructions said the starter is captured, so the last thing i needed was to have a new header in place that captured a bad starter.

Starter fluid down the carb and a quick key turn confirmed all was good to proceed with the headers.

Starter fluid down the carb and a quick key turn confirmed all was good to proceed with the headers.

Exhausted... (pardon the pun) that damn drivers side TTi shorty took dam near all day (homemade spaghetti took the rest of the day). Seems to have fit perfectly... once I pulled the starter lifted up the motor again.

Long story short... passenger side is in as well. I Chose to lift the motor yet again, as opposed to waiting around for a good T-bar removal tool. I Was a bit surprised to see that the passenger side #8 tube pressed firmly against a bump-out in the inner fender. Not seeing it as a big deal for my purposes.

View attachment 1715497415

View attachment 1715497415

If I had a nickel for every time I got up off the floor in the last week...

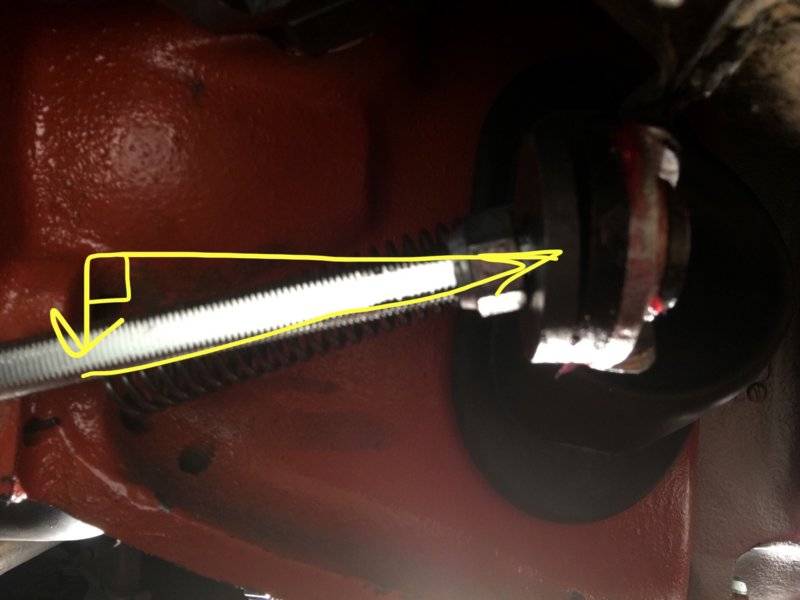

Modified Z bar (TTi) and clutch linkage...

Surprisingly, this all went in perfectly (pretty much), considering the cramped space. Since my modified Z bar, bell-side mounting stud (actually Ebay), and headers came from TTi, and my clutch linkage came from Brewers (I think... it’s been a while), I assumed I was going to be in pretty good shape.

It became pretty obvious toward the end of the install that the rod-to-clutch-fork side of my Z bar was hanging too low, causing too much of an upward angle to the clutch fork... common issue, I know. I knew that my components were correct, and that I didn’t have any room to shim the engine up, so I decided on modifying the “modified Z bar”. I also checked the fitment of the header extensions in relation to the Z bar. There appears to be ZERO room, especially with the 1.03” torsion bars, but a little twisting and prying on the 2.5” tubes, it miraculously slid right up to the header. I noticed I’d have to tweak the Z bar on the header side as well....

Surprisingly, this all went in perfectly (pretty much), considering the cramped space. Since my modified Z bar, bell-side mounting stud (actually Ebay), and headers came from TTi, and my clutch linkage came from Brewers (I think... it’s been a while), I assumed I was going to be in pretty good shape.

It became pretty obvious toward the end of the install that the rod-to-clutch-fork side of my Z bar was hanging too low, causing too much of an upward angle to the clutch fork... common issue, I know. I knew that my components were correct, and that I didn’t have any room to shim the engine up, so I decided on modifying the “modified Z bar”. I also checked the fitment of the header extensions in relation to the Z bar. There appears to be ZERO room, especially with the 1.03” torsion bars, but a little twisting and prying on the 2.5” tubes, it miraculously slid right up to the header. I noticed I’d have to tweak the Z bar on the header side as well....

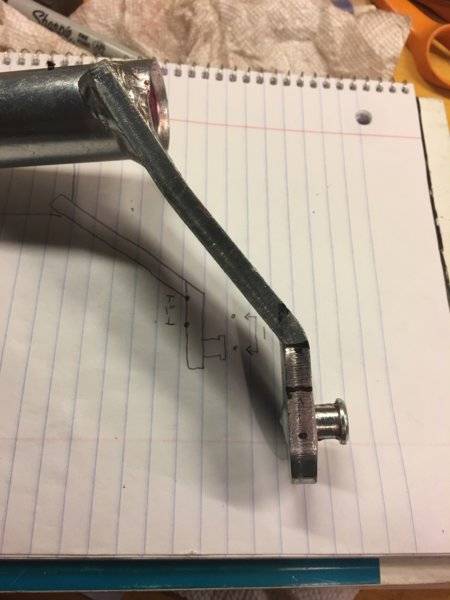

Modified Z bar modification...

I slept on it and thought out several options to move the linkage “peg” up approximately 1”. I settled on my first thought... don’t be afraid to use a saws-all in situations like this. I don’t have a band saw, and I knew a cut-off wheel would be a little janky for this job, so I decided on my saws-all. Luckily I had new blades on hand. I used a small, sharp edged file to cut some little grooves for the blade to get started... Also, I decided I needed to keep as much of the supporting surface area around the peg to allow the plastic bushing and fork pushrod to function correctly.

I slept on it and thought out several options to move the linkage “peg” up approximately 1”. I settled on my first thought... don’t be afraid to use a saws-all in situations like this. I don’t have a band saw, and I knew a cut-off wheel would be a little janky for this job, so I decided on my saws-all. Luckily I had new blades on hand. I used a small, sharp edged file to cut some little grooves for the blade to get started... Also, I decided I needed to keep as much of the supporting surface area around the peg to allow the plastic bushing and fork pushrod to function correctly.

Last edited:

I don’t weld enough to be great at it, but I love getting after it. I know I could get pretty decent with more practice, but whatever, I’m about moving forward, with little fear (which I had in the old days). Don’t whine if something isn’t right, just go ahead and solve the problem (with FABO help if you need it), pat yourself on the back, and smile into a cold beer when you’re done.

Fuel system coming online... hopefully...

Clutch fork rod alignment looking MUCH better now (no pic yet), but still wasn’t happy with the lack of clutch plate disengagement. Definitely wasn’t the .040-.060” I keep reading. Also.. very sloppy clutch pedal (bushings shot/gone.. C clip gone), so ordered a new bushing and clip kit from Brewers. Since my clutch pedal was about 1.5” short of lining up with my brake pedal, I Decided to also pull the clutch pedal to torque shaft rod to check for wear. The “holes” were completely rounded out... and, most importantly... the rod was about 3” shorter than the 14.25” Brewer said it should be! Seems like a previous owner just used what they had on-hand. The Z bar I pulled way back when also looked like a homemade jobber, so maybe the combo worked just fine at the time ;) So, I added a new rod to my Brewers order as well.

Also.. good to see my workbench again!

Also.. good to see my workbench again!

The Right Stuff prebent fuel line was pretty spot on, and required an ideal amount or prodding to get it to wedge into several places.

Trashed the fuel tank grommet with a case of impatience, so waiting on another (I know exactly where I went wrong.. and will document it when completed).

Rebuilding the clutch/brake pedal assembly now... super close on this. I almost skipped pulling the brake pedal out, since the mechanism felt pretty good. But I’m glad I went further and pulled it (that little nut/bolt combo holding it made me wish my fingers were 1” longer and made of rubber) Thankfully, I was able to do this without pulling the main supporting bracket (I just didn’t want to detach my master cylinder again). I’ll do a write-up on this if nobody else has... very tricky and requires ordered steps and the use of muscles in my hand I never knew I had. So far, I’ve escaped a chipped tooth from a falling 3/8” ratchet!

Rebuild kit from Brewers is dead on! One of the original (I’m assuming) clutch bushings was totally gone.

Looking forward to seeing how the clutch rod fits. I’m hoping the pedal will feel like new.

Rebuilding the clutch/brake pedal assembly now... super close on this. I almost skipped pulling the brake pedal out, since the mechanism felt pretty good. But I’m glad I went further and pulled it (that little nut/bolt combo holding it made me wish my fingers were 1” longer and made of rubber) Thankfully, I was able to do this without pulling the main supporting bracket (I just didn’t want to detach my master cylinder again). I’ll do a write-up on this if nobody else has... very tricky and requires ordered steps and the use of muscles in my hand I never knew I had. So far, I’ve escaped a chipped tooth from a falling 3/8” ratchet!

Rebuild kit from Brewers is dead on! One of the original (I’m assuming) clutch bushings was totally gone.

Looking forward to seeing how the clutch rod fits. I’m hoping the pedal will feel like new.

Last edited:

My pedal assembly is all back together and feeling fresh!

The new clutch pedal rod went in fine, and the extra length on the rod has brought my clutch back pedal out next to my brake pedal, which is giving me the extra travel and clutch disengagement that I needed.

Fuel tank and filler tube also went in quick and strapped up nicely.

The new clutch pedal rod went in fine, and the extra length on the rod has brought my clutch back pedal out next to my brake pedal, which is giving me the extra travel and clutch disengagement that I needed.

Fuel tank and filler tube also went in quick and strapped up nicely.

Extension tubes went on today. Good god... big block in an a body. Whatever. Now I really feel like I’ve been hazed. My wrists and knuckles are cut and scoured... my fingers fatigued... never yelled so many four letter words from simple dropped nuts and bolts. Never threaded one, but six different bolts ten different times using about .020” to .030” of fingertips!!

Definitely had to put the torch and hammer to the tubes today (several times) to get down past the gas pedal bump out in the firewall. Also the pinch seem under the gas pedal. The passenger side was a little easier... I might be a little too close to the 1.03” t-bar... about 1/8”. We’ll see, but for now I’m calling it ‘good.’

Also... if you have a magnet pad... they work wonders for anything under the car!

Definitely had to put the torch and hammer to the tubes today (several times) to get down past the gas pedal bump out in the firewall. Also the pinch seem under the gas pedal. The passenger side was a little easier... I might be a little too close to the 1.03” t-bar... about 1/8”. We’ll see, but for now I’m calling it ‘good.’

Also... if you have a magnet pad... they work wonders for anything under the car!

Steering column is back in place. Getting that collar back on is a bear (with the master cyl in the way... so had to hang that up and out of the way).

Cut new spark plug wires.

Fuel lines 100% in place (bent new lines from carb to near pump, and pump to near line from rear).

installed a front end kit (440 Source: alternator, PS pump, belts, brackets)...

Cut new spark plug wires.

Fuel lines 100% in place (bent new lines from carb to near pump, and pump to near line from rear).

installed a front end kit (440 Source: alternator, PS pump, belts, brackets)...

Last edited:

I’ve personally seen a lack of a clutch safety switch go really wrong... thankfully nobody got seriously hurt... picture someone in your garage... maybe not knowing manual transmissions... or knowing only modern manual transmissions just trying to help you by reaching into the car and turning the key to see if the new starter works.

So, I rigged a clutch safety switch by tapping into the starter solenoid ignition (key turn to ‘start’) wire. The starter solenoid wire was clipped and in between I installed a $9 Yamaha vintage motorcycle spring-loaded brake light switch for the clutch pedal side. I also fabbed a simple bracket and anchored it through an existing hole in the clutch/brake pedal assembly mounting hardware. Then it was just a matter of cutting a spring to the correct size and watching my indicator light for a completed circuit as a depressed the clutch pedal ()

Also, I drilled a new hole in the firewall and installed a grommet for th new switch wires.

Yeah... I probably could have installed a 1970 starter relay that had a clutch safety switch terminal, but I wanted to do my own thing.

So, I rigged a clutch safety switch by tapping into the starter solenoid ignition (key turn to ‘start’) wire. The starter solenoid wire was clipped and in between I installed a $9 Yamaha vintage motorcycle spring-loaded brake light switch for the clutch pedal side. I also fabbed a simple bracket and anchored it through an existing hole in the clutch/brake pedal assembly mounting hardware. Then it was just a matter of cutting a spring to the correct size and watching my indicator light for a completed circuit as a depressed the clutch pedal ()

Also, I drilled a new hole in the firewall and installed a grommet for th new switch wires.

Yeah... I probably could have installed a 1970 starter relay that had a clutch safety switch terminal, but I wanted to do my own thing.

-