70Lawn_Dart

#moparlawndart

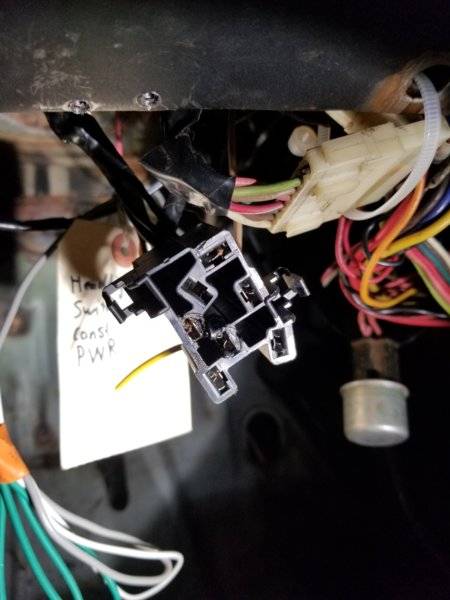

I'm starting to find the small "issues" as to why my car was given up on by the previous owner(s). Still waiting on my buddy to weld the relocation brackets for the rear axle so I decided to throw fuses in and test all electrical circuits...well my AFR gauge sparked and popped the fuse for gauge power, that was cool. On to testing the lights and turn signals... headlamps work and floor switch actually works! Turn signals, flashers and brake lights all work too, then comes the running lights and gauge illumination: no running lights at all and no illumination, but when you have the turn signals on, the gauge lights flash. Upon further inspection, I found the headlamp switch shorted out at some point and melted the connector. Good thing I have a parts car in the backyard that's willing to donate. She's given alot and will continue to provide until there's nothing left but rust and bondo