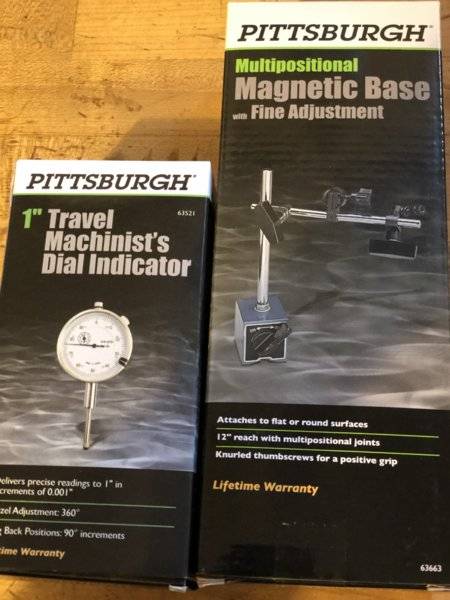

I picked up a dial indicator today for $28 at harbor freight. Nothing fancy but it gets me in the ball park. My input shaft end play was right at .037, following Tom hands guide 727 should be between .036 to .084. I’m hoping thrust washers and mating services look good when I pull the pump.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

727 Time to rebuild

- Thread starter 67/6barracuda

- Start date

-

CudaFactHackJob

Well-Known Member

For those who may not be aware; the pump doesn't just fall out when you take the bolts out because there's a large rubber sealing ring all the way around the pump in a groove.

CudaFactHackJob

Well-Known Member

Sometimes you need to tap the input shaft in when checking end play.

Consider your idea stolen! !!

That's slick! Much better than a slide hammer!

Jeff

I’ll give the input shaft a few love taps to make sure it’s all the way back to verify.Sometimes you need to tap the input shaft in when checking end play.

Dug a little more into the transmission to see if things were looking good. I noticed that the front planetary appears a little ruffed up and so is the piston. what clearance problem would cause this problem? I have one small brass looking washer that separates the two. It measures .074. Doesn’t appear to bad but you can tell that they met each other at some point. Maybe trash got between the two and made it’s mark, who knows?

The 4 front clutches and steels all look great, no excess wear or hot spots. The wavy locking ring measures .081” from its highest point. Counted 10 return springs. I through it all back together and probably run it as is hoping all the seals are still good. I did do a 35psi test before I tore into it and it checked out.

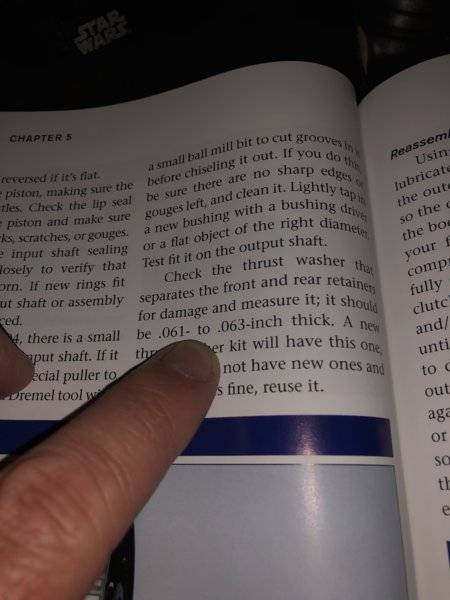

I think I found the problem. The thrust washer is .080, according to VEOTOM’s book looks like it should be between .061 to .063. I measured another one I had and it was .062. Wonder why this thicker one was in there, perhaps to tighten up the input shaft end play which was on the low tolerance side of just .037.

Not ur problem. U r good with 37. Kim

The thrust washers take up the clearances between the drums and between the pump and drum. U need a happy medium for them to work properly. Ur clearances are all good. Kim

As u can see on ur front pressure plate there is a bunch of burn marks. Someone has been in there b4. There is selective snap rings to tighten up the clearances if ur wanting to. If it’s just stock I would tighten up the clearance to .060. Kim

CudaFactHackJob

Well-Known Member

But you're talking .060 BETWEEN THE PLATES, not measured under the high point of the snap ring? And how does the ring surface inside the front drum look? AND can you tell from the edge of the rear band if it's worn or burnt? Just loosen it and move it around a little to see if the rear drum is burnt. AND how about a pic of the front band? AND is the band surface of the front drum smooth? Put all the thrust washers back the same way. We haven't found the direct clutch problem yet. You may have a seal problem in the direct clutch if the rings and ring wear surface inside the drum check out okay.

Last edited:

CudaFactHackJob

Well-Known Member

You might have a direct clutch seal problem if the inside of the direct drum checks out smooth. Did you put the pump in a vise and put the direct drum on it and air check it that way? Be sure all the clutches and snap ring are installed. That piston should check out air tight.

fishy68

Tyr Fryr's Inc.

Even though there's supposed to be a .062 washer in there I've seen 727's operate fine with a .084 in them. Someone probably put it in to reduce end play. Since your in there you might as well replace it with the correct one and use a thicker washer between the pump and front drum to get the clearance tightened up. BTW: I have ran the end play as tight as .018" with no problems. In fact I generally shoot for .020" clearance or as close as I can get to it but don't be alarmed if you can't get it that tight with the thickest washer in the front. Seen many that would only come down to .035" or soI think I found the problem. The thrust washer is .080, according to VEOTOM’s book looks like it should be between .061 to .063. I measured another one I had and it was .062. Wonder why this thicker one was in there, perhaps to tighten up the input shaft end play which was on the low tolerance side of just .037.View attachment 1715333886 View attachment 1715333887 View attachment 1715333918

Fishy, that’s true. Kim

CudaFactHackJob

Well-Known Member

I almost always put a thick one between the drums and two thin ones at the pump. But .018 is scarey. Maybe on an ice cold case, but if it's been in the SoCal sun and l set it that tight, it's gonna lock up come sundown.

The rear clutch is absolutely smoked. My clutches look like burnt up steels nothing left to them. Well that made up my mind, full rebuild in order. I was hoping the clutches where as clean as the froward clutch. Not even close.

CudaFactHackJob

Well-Known Member

Ya that burnt clutch makes sense with what was in the pan. I'm sure glad you didn't just change the fluid and filter and install that crispy critter. Forget a full rebuild; it was already rebuilt recently. Just check that rear band. And are you EVER going to check inside the direct drum for ring scoring? It's something you always have to check no matter what.

MrJLR

Built, not bought

It's on the bench, and the parts are cheap...go for it!

Jeff

Jeff

The drum appears to be okay no scratches or rough edges in side. The seal on the piston is a bit hard but not broken or distorted. The bands have seen there duty life cycle both front and rear.Ya that burnt clutch makes sense with what was in the pan. I'm sure glad you didn't just change the fluid and filter and install that crispy critter. Forget a full rebuild; it was already rebuilt recently. Just check that rear band. And are you EVER going to check inside the direct drum for ring scoring? It's something you always have to check no matter what.

CudaFactHackJob

Well-Known Member

I can't really make out the condition of the rear band, but the rear drum has a scorched strip so the band is "probably" black. If the rear band is dark brown and not flaked or worn then it's fine. Maybe a previous band scorched that drum. Front band is okay, but kevlar on ebay is dirt cheap. Got a pic of the inside of the front drum from the front where the rings ride? And don't forget the lip seal on the center post of the direct drum.

So I’m not sure about the drum, the inside where the reaction shaft rides does have some wear grooves. I can feel them as I run my finger over them. Also, the band service has some wear as well not as smooth as I would like.

CudaFactHackJob

Well-Known Member

if that groove from ring wear is .002 or more, it's absolute junk. You'll hear lots of people say to just sand it down or machine it and it will be fine...but it won't. If you can feel them with your finger; that's pretty bad. The direct clutch is the achilles heel of the 727; it needs to be perfect. My local guy gets $35 for a good used drum.

I found the culprit of failure. Busted seal, explains why the rear clutches are smoked. The edge of the piston is chewed up too. As you can see in the first photo.

Trying to get back on task here. I since abandoned the transmission I was working on rebuilding, it seemed like every part was within its last service life, the pump, drums, etc. I have finally taken my other transmission out of my car, tore it down and determined it’s in much better shape. I got the front clutch together today, it spec out at .099” with a wavy ring and 4 clutches/steels. I may have went a little to far installing the bushing. Hope I can get away with it as is. I also didn’t like how the piston went in, I hope the seal didn’t get twisted up. I’ll check with air, once the pump is together. I’ll be using a 3.8 kick down lever so I went with the 12 springs. That seems to be a general consensus.

CudaFactHackJob

Well-Known Member

If you keep snagging it, put a tight rubber band around it and put it in the freezer for half an hour. the drum too.

-

Similar threads

- Replies

- 15

- Views

- 377

- Replies

- 5

- Views

- 326

- Replies

- 9

- Views

- 606

- Replies

- 34

- Views

- 2K