blown71duster

Well-Known Member

Installing new ring and pinion 4:10 gears and new Eaton trutrac limited slip differential, thought I would take some pictures during the build.

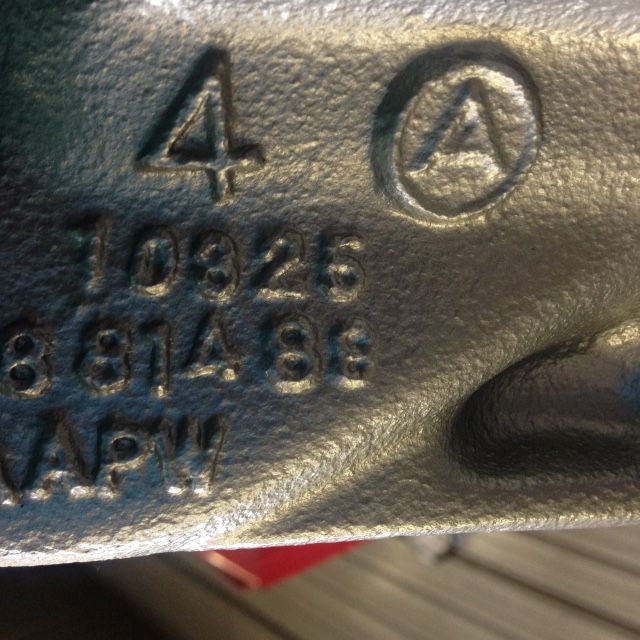

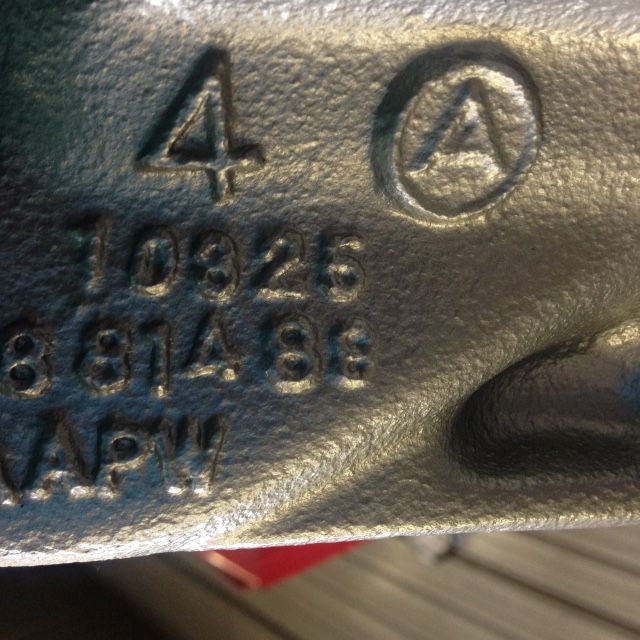

Using a "489" case:

Installed the ring gear on the differential, These are left handed threads-Torque to 55 ft lbs:

Used the press to install the carrier bearings:

Made a set up bearing out of the old pinion bearing, Not shown I used a clamshell style bearing remover , which can remove bearings without damage. Using a Dremel with a sanding roll. Took just enough to allow it to slip on and off while I checked pinion gear depth;

I chose to use the Solid pinion spacer to replace the factory crush sleeve:

I measured the stock crush sleeve to determine what length the solid spacer needed to be, use the shims provided with the kit to set the pinion bearing preload:

Use an Inch pound torque wrench to check rotating torque,FSM spec for new bearings is 20-30 inch pounds:

Use the shims for setting pinion bearing preload and pinion gear depth :

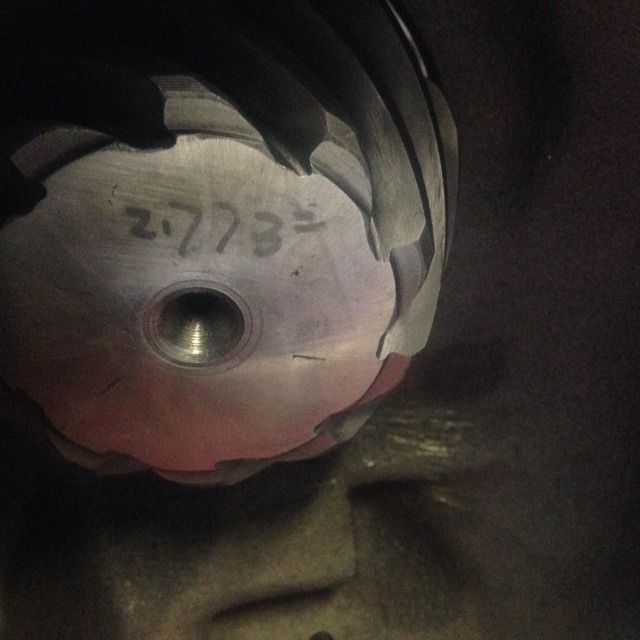

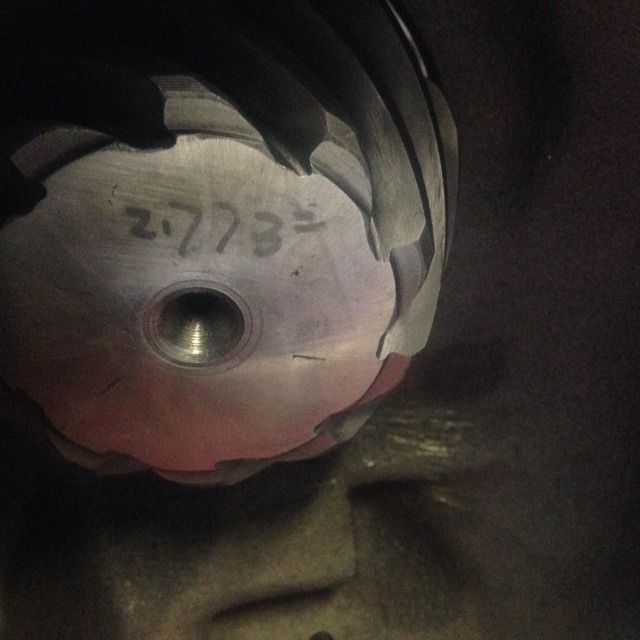

Set the pinion gear depth, depth spec for this is 2.773 inches:

To determine the exact pinion depth I used a T&D pinion depth checker :

The T&D tool uses a dial indicator used with a specific extension and magnetic plate to check depth:

You get your measurement to the top of the pinion gear,shown is my measurement of .602 . You then subtract from their pre- determined spec of 3.375". Which is distance of the recommended 2.773"

Once the shims are figured out then the new bearing gets pressed on:

Torque with a new pinion nut, used a yoke flange holding tool:

Install the sure grip unit, Trutrac with the new bearings on it and install the adjusters:

Using the spanner wrench tighten the carrier bearings. Tighten just one of the bolts on each bearing cap at 85-90 to set the backlash:

Use a dial indicator to set the backlash fsm spec is .006-.010" "

Check this spec at 4 places :

Once you get the backlash set , torque both main caps to 85-90 ft lbs. Then apply your gear marking compound and check that your gear patterns are good:

Using a "489" case:

Installed the ring gear on the differential, These are left handed threads-Torque to 55 ft lbs:

Used the press to install the carrier bearings:

Made a set up bearing out of the old pinion bearing, Not shown I used a clamshell style bearing remover , which can remove bearings without damage. Using a Dremel with a sanding roll. Took just enough to allow it to slip on and off while I checked pinion gear depth;

I chose to use the Solid pinion spacer to replace the factory crush sleeve:

I measured the stock crush sleeve to determine what length the solid spacer needed to be, use the shims provided with the kit to set the pinion bearing preload:

Use an Inch pound torque wrench to check rotating torque,FSM spec for new bearings is 20-30 inch pounds:

Use the shims for setting pinion bearing preload and pinion gear depth :

Set the pinion gear depth, depth spec for this is 2.773 inches:

To determine the exact pinion depth I used a T&D pinion depth checker :

The T&D tool uses a dial indicator used with a specific extension and magnetic plate to check depth:

You get your measurement to the top of the pinion gear,shown is my measurement of .602 . You then subtract from their pre- determined spec of 3.375". Which is distance of the recommended 2.773"

Once the shims are figured out then the new bearing gets pressed on:

Torque with a new pinion nut, used a yoke flange holding tool:

Install the sure grip unit, Trutrac with the new bearings on it and install the adjusters:

Using the spanner wrench tighten the carrier bearings. Tighten just one of the bolts on each bearing cap at 85-90 to set the backlash:

Use a dial indicator to set the backlash fsm spec is .006-.010" "

Check this spec at 4 places :

Once you get the backlash set , torque both main caps to 85-90 ft lbs. Then apply your gear marking compound and check that your gear patterns are good: