Mopar-Man

Big Block Better Burnout

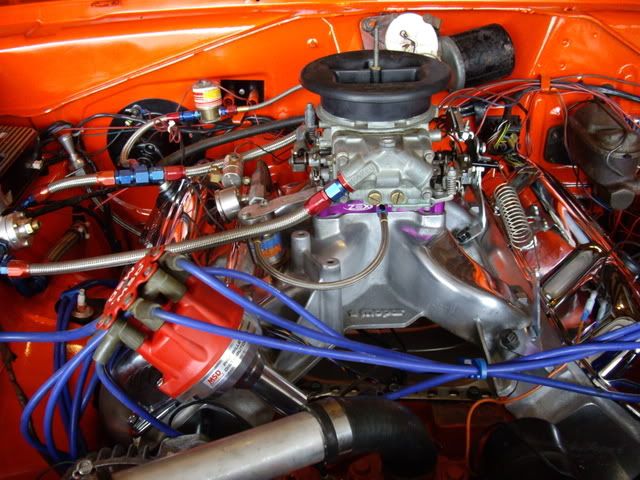

A good friend who is a professional engine builder stopped by today to check the bearings on my 440 since I already had it on the stand and all painted up nice and pretty. When we unbolted the rod caps I got a nasty surprise. While the bearing SURFACES looked great, the edges were shiny and the backsides of the bearing actually transfered metal to the caps! We had a hard time getting the caps off. Here is the best part: When I bought this engine it came fully documented with receipts for parts and labor which stated: "68 440 six pack crank and rods". Guess what we found? Yup, good ol' LY rods. Man, I hate liars. So the rods are junk. At least they were floated and everything was balanced. We pulled the main caps and the crank and bearings are PERFECT so I don't understand what happened with the rod bearing backs. My friend thinks it was simply over-revved too many times. I shifted it at 6500 so I don't have any ideas.

We then pulled the heads off and got surprise #2. Somehow it got moisture in #8 and ate up the top of the piston (pits) and the cylinder wall. Will be lucky to clean up at .060 over. :spiderma: This sucker is all done.

Next we picked it up and set in the back of his pickup. Gee, that was heavy. Did you notice how the Dodge Ram bed is 4 feet high? I think I will feel that tomorrow. Still had crank, cam, timing set, and balancer.

He has a low deck and we are probably just going to build a 451. I am pricing parts out now. He also has some Stage 6 heads. I just want a mid-10 second time and I would be happy.

Thanks for letting me vent and I hope you all learned from my mistakes.

We then pulled the heads off and got surprise #2. Somehow it got moisture in #8 and ate up the top of the piston (pits) and the cylinder wall. Will be lucky to clean up at .060 over. :spiderma: This sucker is all done.

Next we picked it up and set in the back of his pickup. Gee, that was heavy. Did you notice how the Dodge Ram bed is 4 feet high? I think I will feel that tomorrow. Still had crank, cam, timing set, and balancer.

He has a low deck and we are probably just going to build a 451. I am pricing parts out now. He also has some Stage 6 heads. I just want a mid-10 second time and I would be happy.

Thanks for letting me vent and I hope you all learned from my mistakes.