Don't think you have enough R134 freon in the system yet, here is a reference to a 1974 Charger AC system that takes around 34 oz. of freon.

If you have a site glass on your reciever dryer you can watch for bubbles there, when the bubbles are gone the system is full.

Usually put a thermometer in the Dash AC outlet to watch the output temp. You won't get any drop in temp till there is enough freon in the system. At first it will pull down to around 65 degrees, keep adding til the temp gets around 55 degrees.

Can jump the compressor to keep it pumping as you are filling the system, once you get enough freon in the system you can take the jumper off and finish the fill.

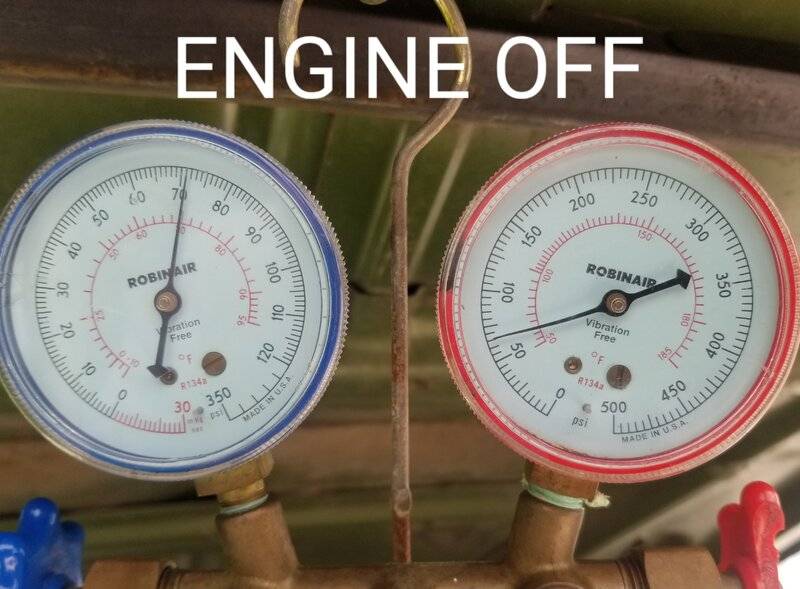

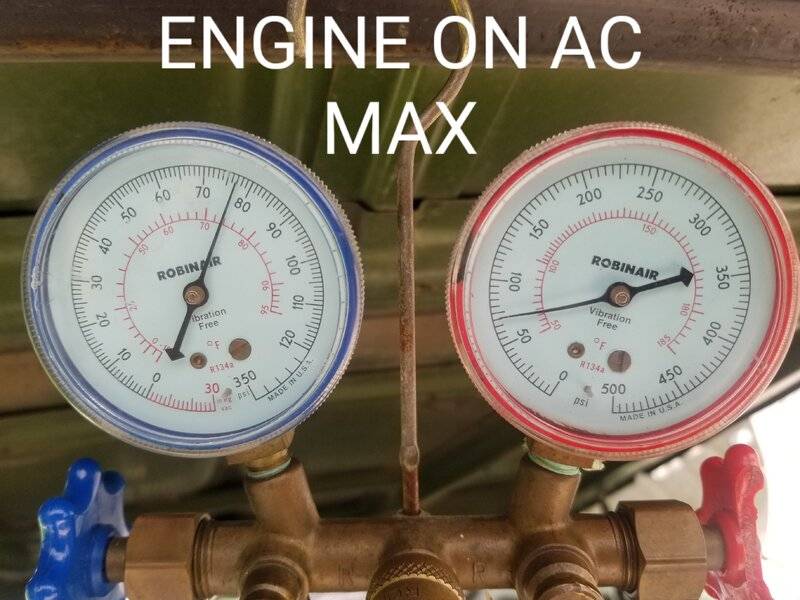

Here is the example:

The proper R134a charge rate — or charge capacity — for all vehicles is most often between 70-80% percent of the original R12 refrigerant charge rate. That should be listed in your service manual. (If you don’t have one, you can find them at

moparmanuals.com, among other places.) A 1974 Dodge Charger came originally charged at 3.25 lbs of R12 from the factory, which would take 36-42 oz of R134a (3.25 lbs @ 16 oz per lb = 52 oz x 70% = 36.4 oz).

We typically recommend that you start at the 70% mark (in this case 36.4 oz) and watch your gauge readings and temperature using a thermometer in the center vent with your air volume on high. Add 1 – 1.5 oz and repeat the procedure until you’ve reached your coldest vent temperature and your system pressures are within a comfortable range.

3.25 lbs > 70% > 36.4 oz freon.

As the system is filling your low pressure side line should start to feel cold, You should be safe with 30 oz. of freon to start with and see if it starts coming around, if all is good continue adding until inerior temp is in the mid 50s.

Napa has new AC compressors for 72 Darts for around 200, but fill your system first.

Sometimes you have to put the freon cans in hot water as you are recharging the system if it is cooler day to help push the freon into the system.