I think air takes the path of least resistance first. Through the kill bleed and any emulsion holes not covered by fuel until their capacity is exceeded and it becomes easier to pass through the fuel covered holes. Don't know if that's right.@92b Its great to see some testing. What 750 dp was your test conducted with? Main bodies? Metering blocks? Emulsion pack?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Annular boosters on a Tunnel Ram

- Thread starter MomsDuster

- Start date

-

Rat Bastid

Dunamis Metron

I think air takes the path of least resistance first. Through the kill bleed and any emulsion holes not covered by fuel until their capacity is exceeded and it becomes easier to pass through the fuel covered holes. Don't know if that's right.

View attachment 1716030933

Somehow the area of all the bleeds involved makes a difference.

I know it’s in the math of some of these books. Greater area at the same pressure changes the differential of all the bleeds IIRC.

Its easy to get lost.

I think it's easier to test and observe the results than it is to predict the results.Somehow the area of all the bleeds involved makes a difference.

I know it’s in the math of some of these books. Greater area at the same pressure changes the differential of all the bleeds IIRC.

Its easy to get lost.

Rat Bastid

Dunamis Metron

I think it's easier to test and observe the results than it is to predict the results.

I agree. I use the math (when I have to) to get me close if I’m having issues with a tune up.

TT5.9mag

Two atmospheres are better than one

Another very informative post by Yeti on YB.

“At part-throttle and the low airflow conditions present near the beginning of and in the lower range of main discharge flow, the addition of emulsion air causes richer fuel delivery with the same size jet and venturi vacuum signal because the addition of air to the fuel in the main well pushes the fuel up the well toward the discharge nozzle in the booster (the same as carbonation foam pushes beer up and out a longneck beer bottle). In carbs with the main system flow path dimensions similar to the common Holley 4150, adding emulsion air causes low flow to be richer before it causes high flow to be leaner.”

“At part-throttle and the low airflow conditions present near the beginning of and in the lower range of main discharge flow, the addition of emulsion air causes richer fuel delivery with the same size jet and venturi vacuum signal because the addition of air to the fuel in the main well pushes the fuel up the well toward the discharge nozzle in the booster (the same as carbonation foam pushes beer up and out a longneck beer bottle). In carbs with the main system flow path dimensions similar to the common Holley 4150, adding emulsion air causes low flow to be richer before it causes high flow to be leaner.”

Sounds like he is describing behavior after the begining of main system fuel flow. Is that how you read it?Another very informative post by Yeti on YB.

“At part-throttle and the low airflow conditions present near the beginning of and in the lower range of main discharge flow, the addition of emulsion air causes richer fuel delivery with the same size jet and venturi vacuum signal because the addition of air to the fuel in the main well pushes the fuel up the well toward the discharge nozzle in the booster (the same as carbonation foam pushes beer up and out a longneck beer bottle). In carbs with the main system flow path dimensions similar to the common Holley 4150, adding emulsion air causes low flow to be richer before it causes high flow to be leaner.”

Rat Bastid

Dunamis Metron

Sounds like he is describing behavior after the begining of main system fuel flow. Is that how you read it?

What he’s saying is that at the initiation of flow to the booster the main air bleed acts like an emulsion bleed and starts the mains sooner and makes the fuel curve slightly richer at start up before the MAB makes the fuel curve tilt leaner at high air flows.

Thats why I’ve been saying pressure differential matters, the area of the jet/bleed matter and even the booster makes a difference.

And as I’ve said, just because a bleed exhibits a certain characteristic at high air flows doesn’t mean it has that same characteristic at low flows.

And the guy waving the banner the highest says that’s NOT what Yeti and Shrinker are saying. I can’t ask Bruce (Shrinker) because he has passed but I can ask Yeti. And that’s exactly what he says and what he writes.

All my testing says the same thing.

How do you test booster start up rpm?What he’s saying is that at the initiation of flow to the booster the main air bleed acts like an emulsion bleed and starts the mains sooner and makes the fuel curve slightly richer at start up before the MAB makes the fuel curve tilt leaner at high air flows.

Thats why I’ve been saying pressure differential matters, the area of the jet/bleed matter and even the booster makes a difference.

And as I’ve said, just because a bleed exhibits a certain characteristic at high air flows doesn’t mean it has that same characteristic at low flows.

And the guy waving the banner the highest says that’s NOT what Yeti and Shrinker are saying. I can’t ask Bruce (Shrinker) because he has passed but I can ask Yeti. And that’s exactly what he says and what he writes.

All my testing says the same thing.

How do you test booster start up rpm?

I guess I'm asking is if main air bleed size affects the point in time or rpm that the booster starts flowing either sooner or later why when I tested this did changing the main air bleed from .025 to .035 then .045 at the same load did the booster start up occur at the same rpm? I think that .025-.045 would be the whole range of possible bleed sizes used in most common applications. Is there something I'm doing wrong in the way I tested this?What he’s saying is that at the initiation of flow to the booster the main air bleed acts like an emulsion bleed and starts the mains sooner and makes the fuel curve slightly richer at start up before the MAB makes the fuel curve tilt leaner at high air flows.

Thats why I’ve been saying pressure differential matters, the area of the jet/bleed matter and even the booster makes a difference.

And as I’ve said, just because a bleed exhibits a certain characteristic at high air flows doesn’t mean it has that same characteristic at low flows.

And the guy waving the banner the highest says that’s NOT what Yeti and Shrinker are saying. I can’t ask Bruce (Shrinker) because he has passed but I can ask Yeti. And that’s exactly what he says and what he writes.

All my testing says the same thing.

The stack is listed in post 126.@92b That’s why I asked about your emulsion stack and how you had your metering blocks set up. There are really no definitives here. How any one particular part functions is very dependent on the rest of the system.

Mattax

Just the facts, ma'am

I'd say for one there are too many holes.

My version of the answer to your question about testing method is this.

The range of MAB's tested is too wide. Between .025 and .035"

The e-bleeds are way outside of the working range. 2 e-holes about .026 to .28 or Mark W says he's had good results with some applications with three, but smaller, like .020" dia IIRC.

The kill bleed can help the intiation of flow when it does start. It may slightly delay that initiation.

That's a big main jet but I didn't look at the application or even the carb.

My version of the answer to your question about testing method is this.

The range of MAB's tested is too wide. Between .025 and .035"

The e-bleeds are way outside of the working range. 2 e-holes about .026 to .28 or Mark W says he's had good results with some applications with three, but smaller, like .020" dia IIRC.

The kill bleed can help the intiation of flow when it does start. It may slightly delay that initiation.

That's a big main jet but I didn't look at the application or even the carb.

When people talk about the main system coming in sooner or later I have always assumed they were referring to rpms. When I said time based I was referring to rpm as time. I should have just said rpm. I get that the throttle position changes where the boosters start flowing at different loads. But you have to have some sort of reference to make a comparison. I guess I could use throttle percent opening but I would have to rig up a throttle position potentiometer that produces a 0 to 5 volt signal and convert that to percent of opening. Really I think the results would be the same as using rpm. Wouldn't they? I don't know.And really it’s not time or rpm based. It’s signal based which would be load and throttle position (pressure differential).

Mattax

Just the facts, ma'am

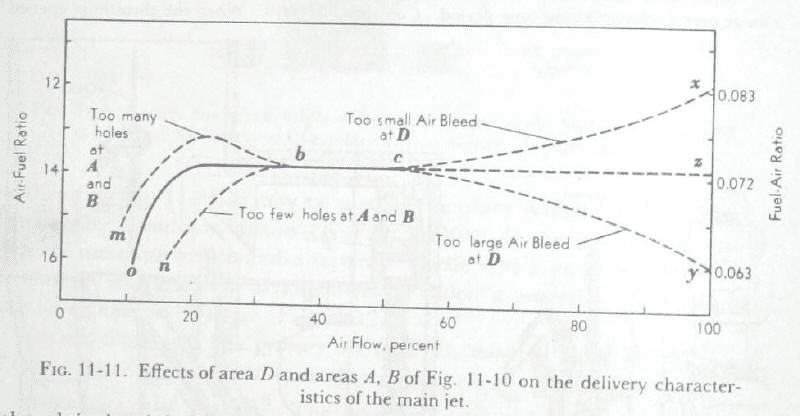

Are you all familiar with this?

D is the main air bleed.

A and B are the holes in the air tube (air well) in the main well. that is "emulsion holes"

When the holes in the well are bit too big, or there are too many, the fuel will start to flow sooner but may go rich then lean before stabilalizing.

That can also happen to some extent if the main air bleed is too big.

The way to approach the problem is to use the main air bleed to insure the AFR stays flat through the top rpm we need. That's the main job of the air bleed system. With that established then experiment with the e-holes.

Does it always work that neatly? Maybe for someone with more experience, but its how I try to work it in.

The MAB and e-holes have to be in the ballpark or its going to be pretty unpredictable.

D is the main air bleed.

A and B are the holes in the air tube (air well) in the main well. that is "emulsion holes"

When the holes in the well are bit too big, or there are too many, the fuel will start to flow sooner but may go rich then lean before stabilalizing.

That can also happen to some extent if the main air bleed is too big.

The way to approach the problem is to use the main air bleed to insure the AFR stays flat through the top rpm we need. That's the main job of the air bleed system. With that established then experiment with the e-holes.

Does it always work that neatly? Maybe for someone with more experience, but its how I try to work it in.

The MAB and e-holes have to be in the ballpark or its going to be pretty unpredictable.

Last edited:

TT5.9mag

Two atmospheres are better than one

Use throttle position and MAP as well as an rpm trace.When people talk about the main system coming in sooner or later I have always assumed they were referring to rpms. When I said time based I was referring to rpm as time. I should have just said rpm. I get that the throttle position changes where the boosters start flowing at different loads. But you have to have some sort of reference to make a comparison. I guess I could use throttle percent opening but I would have to rig up a throttle position potentiometer that produces a 0 to 5 volt signal and convert that to percent of opening. Really I think the results would be the same as using rpm. Wouldn't they? I don't know.

Mattax

Just the facts, ma'am

I can tell you the answer is no.When people talk about the main system coming in sooner or later I have always assumed they were referring to rpms. When I said time based I was referring to rpm as time. I should have just said rpm. I get that the throttle position changes where the boosters start flowing at different loads. But you have to have some sort of reference to make a comparison. I guess I could use throttle percent opening but I would have to rig up a throttle position potentiometer that produces a 0 to 5 volt signal and convert that to percent of opening. Really I think the results would be the same as using rpm. Wouldn't they? I don't know.

When I've logged AFR, I've used RPM and vacuum, but having throttle position would make picture clearer.

I haven't been able to pinpoint when the mains begin. (maybe thats a good thing) But I did discover when the main system was providing most of the fuel. Crusing at 55 mph after dyno session was fine, and at 60 mph it went crazy lean (because I left in the lean pair of PMJs of the two best pulls). That was a bit under 3000 rpm with moderate (30???) throttle and around 16 "Hg. I didn't have a logger then.

Mattax

Just the facts, ma'am

cudafever has posted some logs of his quarter mile runs - I can't recall if he had TPS or MAP working.

With a drag run, from launch onward the throttle is wide opn so its not the same questions as we have for street use.

I've posted some logs and tables too. Street, dyno and quarter mile I think. Lemme find the threads.

With a drag run, from launch onward the throttle is wide opn so its not the same questions as we have for street use.

I've posted some logs and tables too. Street, dyno and quarter mile I think. Lemme find the threads.

Mattax

Just the facts, ma'am

Here: 100 cfm more with anular and downleg boosters can't beat AFR

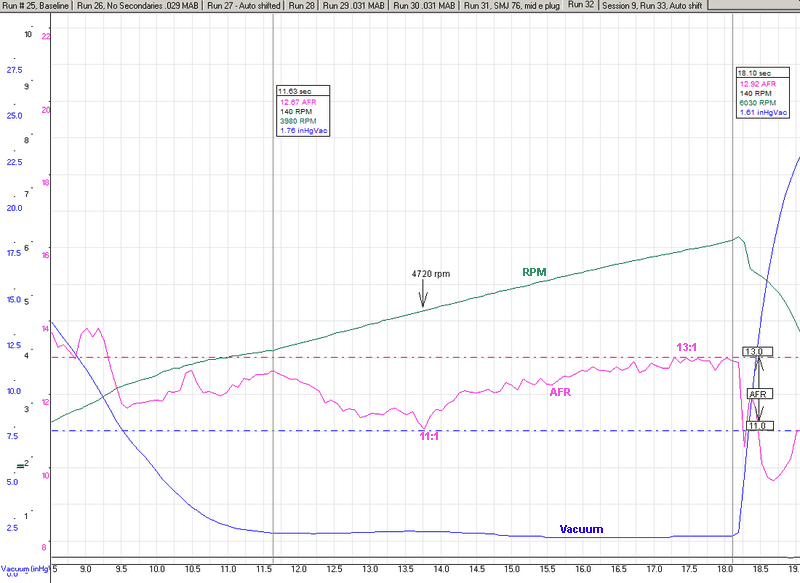

Lets look at the log from the dyno session

Making a dyno pull using only primary side of the carb the AFR stayed flat.

Knowing that, then it must be the secondary side causing the AFRs to drift rich and then lean as seen in the log below.

The secondary high speed airbleeds were later reduced from .033 to equivalent of .029" dia. using wires. This was done after the dyno session since I wasn't prepared for that...

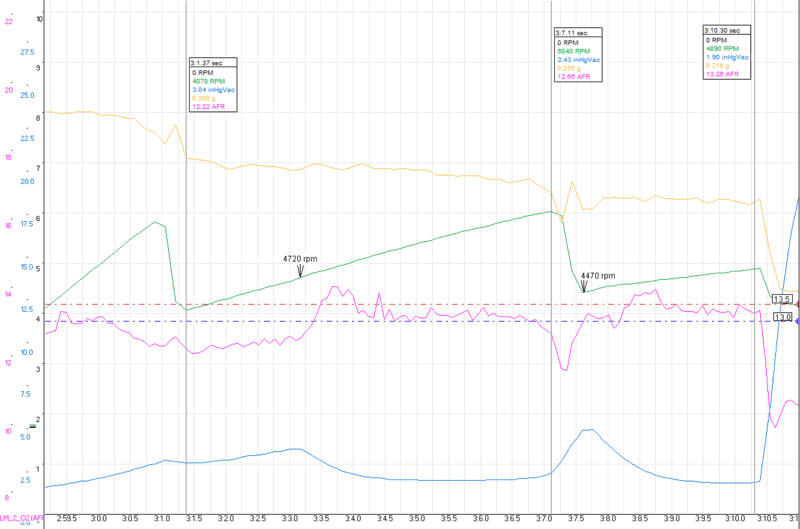

However a drag strip run shows a much flatter AFR in 2nd and 3rd gear, staying largely between 13 and 13.5

Now I feel like that carb's MABs are pretty close to where they ought to be. Now I can make jet changes and secondary spring changes, and maybe even small MAB and emulsion changes...

(whatever was happening before 4700 rpm with the higher vac and rich mix is uncertain but I need to make some better passes as I think I lifted a little)

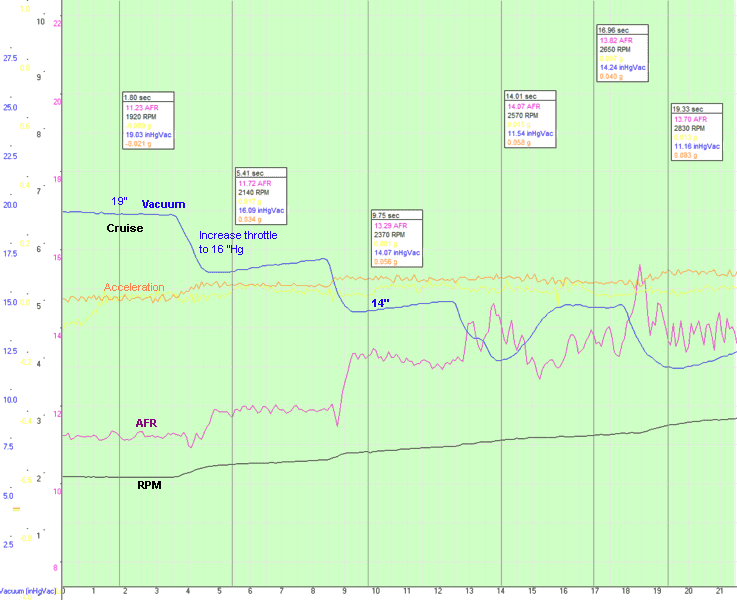

Next example of logging throttle opening without a TPS. (Different carb, different timing, same engine.)

The drop in vacuum is the best indicator here of increased throttle position.

To maintain the vacuum at 16", then 14" etc, required increasing throttle as the rpm increased.

There's really no way to know that just looking at the log.

When I've made tables of mostly steady state driving (removing acceleration and braking as much as possible)

A little show-n'tell in post #11 if your interested.

Lets look at the log from the dyno session

Making a dyno pull using only primary side of the carb the AFR stayed flat.

Knowing that, then it must be the secondary side causing the AFRs to drift rich and then lean as seen in the log below.

The secondary high speed airbleeds were later reduced from .033 to equivalent of .029" dia. using wires. This was done after the dyno session since I wasn't prepared for that...

However a drag strip run shows a much flatter AFR in 2nd and 3rd gear, staying largely between 13 and 13.5

Now I feel like that carb's MABs are pretty close to where they ought to be. Now I can make jet changes and secondary spring changes, and maybe even small MAB and emulsion changes...

(whatever was happening before 4700 rpm with the higher vac and rich mix is uncertain but I need to make some better passes as I think I lifted a little)

Next example of logging throttle opening without a TPS. (Different carb, different timing, same engine.)

The drop in vacuum is the best indicator here of increased throttle position.

To maintain the vacuum at 16", then 14" etc, required increasing throttle as the rpm increased.

There's really no way to know that just looking at the log.

When I've made tables of mostly steady state driving (removing acceleration and braking as much as possible)

A little show-n'tell in post #11 if your interested.

Last edited:

I wasn't tuning this carb to this motor. I only picked it because it already had adjustable bleeds and no choke horn so the're easy to get at.I'd say for one there are too many holes.

My version of the answer to your question about testing method is this.

The range of MAB's tested is too wide. Between .025 and .035"

The e-bleeds are way outside of the working range. 2 e-holes about .026 to .28 or Mark W says he's had good results with some applications with three, but smaller, like .020" dia IIRC.

The kill bleed can help the intiation of flow when it does start. It may slightly delay that initiation.

That's a big main jet but I didn't look at the application or even the carb.

What I was trying to answer with this test was this. How does main air bleed size affect when the main circuit starts flowing fuel? Foolishly I thought this shouldn't take long to figure out.

My thinking was at first to check with no load on the engine. I tried .025 ,.035 and .045". Thinking big steps should show big changes and a clear trend.

The plan was to watch the booster with one eye and the tach with the other eye. Open the throttle until I see fuel dripping from the booster and note the rpm. Simple. I was surprised to see the rpm remain constant.

So I thought I could force a change. Next I put the .025 back in with .015 tag wire in it. Still the booster flowed at the same rpm. Next I took the main air bleeds completely out. Same result.

I thought maybe I need some load on the motor so I put a constant load on the motor and repeated the test. .025, .035 and .045. same result but at a lower rpm. Next I tried more load. Lower rpm same result. By now it was way past bed time and I gave up.

It would be my luck that I picked the one combination that could give these results. I will try this test again when the opportunity presents itself with another carb/ motor. Meanwhile is there someone who would be willing to try at least the unloaded version of this test on their motor in their car. I'm curious to see what your results are. It shouldn't take long. lol

71 GSS,

Your post #107. Sorry for the delay [ time difference ]. The quotes you need are in posts# 19, 27 & 53.

I thought I had included the info from Holley engineer, Mike Urich. Couldn't find it, might have been thinking of another thread.

P. 23 of the Holley book: 'The strong signal from the discharge nozzle is bled off by the main air bleed so there is less effective pressure difference to cause fuel flow. The mixture will become leaner as the size of the air bleed is increased. Decreasing the bleed size increases the pressure drop across the main jet to pull more fuel through.'

Your post #107. Sorry for the delay [ time difference ]. The quotes you need are in posts# 19, 27 & 53.

I thought I had included the info from Holley engineer, Mike Urich. Couldn't find it, might have been thinking of another thread.

P. 23 of the Holley book: 'The strong signal from the discharge nozzle is bled off by the main air bleed so there is less effective pressure difference to cause fuel flow. The mixture will become leaner as the size of the air bleed is increased. Decreasing the bleed size increases the pressure drop across the main jet to pull more fuel through.'

TT5.9mag

Two atmospheres are better than one

Wow you are a data monster. I love your dedication to graphing and plotting your data.Here: 100 cfm more with anular and downleg boosters can't beat AFR

Lets look at the log from the dyno session

Making a dyno pull using only primary side of the carb the AFR stayed flat.

Knowing that, then it must be the secondary side causing the AFRs to drift rich and then lean as seen in the log below.

View attachment 1716031207

The secondary high speed airbleeds were later reduced from .033 to equivalent of .029" dia. using wires. This was done after the dyno session since I wasn't prepared for that...

However a drag strip run shows a much flatter AFR in 2nd and 3rd gear, staying largely between 13 and 13.5

View attachment 1716031209

Now I feel like that carb's MABs are pretty close to where they ought to be. Now I can make jet changes and secondary spring changes, and maybe even small MAB and emulsion changes...

(whatever was happening before 4700 rpm with the higher vac and rich mix is uncertain but I need to make some better passes as I think I lifted a little)

Next example of logging throttle opening without a TPS. (Different carb, different timing, same engine.)

The drop in vacuum is the best indicator here of increased throttle position.

To maintain the vacuum at 16", then 14" etc, required increasing throttle as the rpm increased.

There's really no way to know that just looking at the log.

View attachment 1716031208

When I've made tables of mostly steady state driving (removing acceleration and braking as much as possible)

A little show-n'tell in post #11 if your interested.

Mattax

Just the facts, ma'am

That's interesting. I just back read a little to see what your doing. Wish I was closer. I'm impressed.I wasn't tuning this carb to this motor. I only picked it because it already had adjustable bleeds and no choke horn so the're easy to get at.

What I was trying to answer with this test was this. How does main air bleed size affect when the main circuit starts flowing fuel? Foolishly I thought this shouldn't take long to figure out.

My thinking was at first to check with no load on the engine. I tried .025 ,.035 and .045". Thinking big steps should show big changes and a clear trend.

The plan was to watch the booster with one eye and the tach with the other eye. Open the throttle until I see fuel dripping from the booster and note the rpm. Simple. I was surprised to see the rpm remain constant.

So I thought I could force a change. Next I put the .025 back in with .015 tag wire in it. Still the booster flowed at the same rpm. Next I took the main air bleeds completely out. Same result.

I thought maybe I need some load on the motor so I put a constant load on the motor and repeated the test. .025, .035 and .045. same result but at a lower rpm. Next I tried more load. Lower rpm same result. By now it was way past bed time and I gave up.

It would be my luck that I picked the one combination that could give these results. I will try this test again when the opportunity presents itself with another carb/ motor. Meanwhile is there someone who would be willing to try at least the unloaded version of this test on their motor in their car. I'm curious to see what your results are. It shouldn't take long. lol

View attachment 1716031210

I don't have access to that dyno like I did back then (I still paid for using it but they let me run it)

It's late for me too, but I *think* your observation that MAB has little effect on the initiation fits in with what Obert described in the graph (post #140). Maybe with less e-holes then changes in the MAB might effect initiation more?

TT5.9mag

Two atmospheres are better than one

I’d like to duplicate your test method. Unfortunately the only engine I have that is still currently carbureted (CSU blow through 750) is my 489 BBC twin turbo for my boat. It will be a while before I can test due to weather and my results may be wildly different due to boost. I’ll give it a try though when I can if only for knowledge gains and data shared.I wasn't tuning this carb to this motor. I only picked it because it already had adjustable bleeds and no choke horn so the're easy to get at.

What I was trying to answer with this test was this. How does main air bleed size affect when the main circuit starts flowing fuel? Foolishly I thought this shouldn't take long to figure out.

My thinking was at first to check with no load on the engine. I tried .025 ,.035 and .045". Thinking big steps should show big changes and a clear trend.

The plan was to watch the booster with one eye and the tach with the other eye. Open the throttle until I see fuel dripping from the booster and note the rpm. Simple. I was surprised to see the rpm remain constant.

So I thought I could force a change. Next I put the .025 back in with .015 tag wire in it. Still the booster flowed at the same rpm. Next I took the main air bleeds completely out. Same result.

I thought maybe I need some load on the motor so I put a constant load on the motor and repeated the test. .025, .035 and .045. same result but at a lower rpm. Next I tried more load. Lower rpm same result. By now it was way past bed time and I gave up.

It would be my luck that I picked the one combination that could give these results. I will try this test again when the opportunity presents itself with another carb/ motor. Meanwhile is there someone who would be willing to try at least the unloaded version of this test on their motor in their car. I'm curious to see what your results are. It shouldn't take long. lol

View attachment 1716031210

Last edited:

-

Similar threads

- Replies

- 6

- Views

- 862

- Locked

- Replies

- 0

- Views

- 935

- Locked

- Replies

- 8

- Views

- 2K