jtkaaa07

BossMan

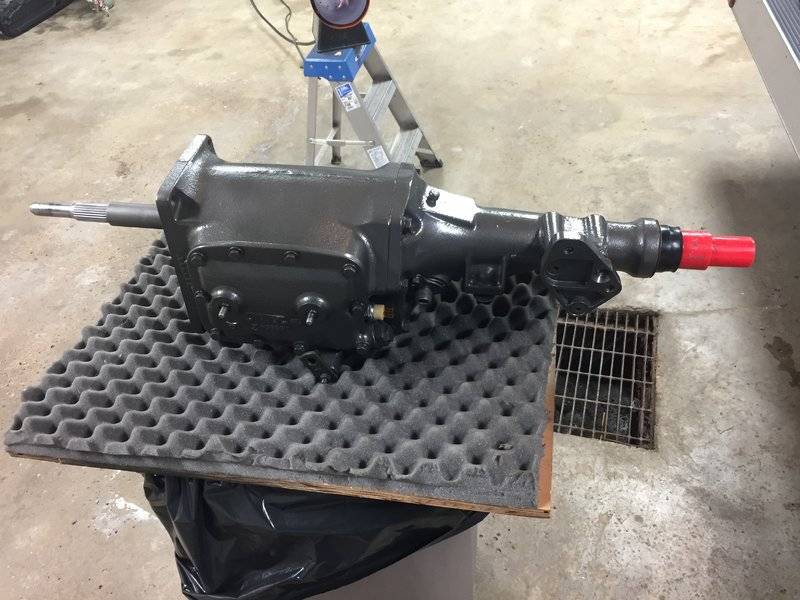

Bored tonight so I decided to finish another 4 speed for a friend, I can't wait for spring, but at least I'm getting some projects done, got 3 more sitting on floor, better get going lol !

oooooo la la!

I always enjoyed doing those.

with all the parts there, just to assemble, with the right tools. it took me about an hr to do my first oneHow many hours does it take you? How hard of a job is it?

Assembly time is not the big factor. Making sure the brass rings can do the job today, and for thousands of miles perhaps many years into the future; that is the big deal. Repointing the clutch teeth takes a bit of time too, as does back-cutting the flanks. Putting new bearings in doesn't eat a lot of time either;

But the real time consumer would be converting it to be able to shift at 7000. Now that's a trick that will cost in the neighborhood of 8 hours with hand tools. But I gotta tell you; shifting at 7200 and knowing it will be almost impossible to miss that shift, and knowing it is gonna pop right in, and you are not gonna pump up the lifters and crash the valves, well that is a mighty fine worry-free feeling. Now I can worry about where the finish-line is, and am I getting there fast enough.heehee.

Agreed! All I see is the snowmobile trailerWhere's the snow?

A kit is available from Brewers now I think

How many hours does it take you? How hard of a job is it?

Yep. 4 speeds are one of my favorite things to do.....is that cast paint? I bead blast the housings and the clear them with high heat engine enamel.View attachment 1715012810

Agreed! All I see is the snowmobile trailer

Did my 4 speed (with v-gate) last year, this year (yesterday) 8000ft peak of mt. Bailey.....View attachment 1715012942View attachment 1715012943

We had lots up until about 10 days ago. Then a chinook came through here, and turned it all to ice. There were a few days, to a week, of beautiful snomobile snow, probably the best snow since 97.