Another Super Victor ready for some flowbench testing. This one is actually mine that I ran 9.73 with 10 plus years ago. I did some updates to it as I’m doing much nicer work now than I did back then. I did a set of Edelbrock heads for an Ohio friend that are done but I’m waiting for his keepers and retainers. And I offered this intake for him to use for the year. I can’t wait to see his results. Another Victor340 on the porting table tomorrow.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Super Victor

- Thread starter pittsburghracer

- Start date

-

Bobzilla

Well-Known Member

That sure looks better than a stock one. I need to start grinding.

What did you do to “update” your porting work? Is it a surface finish or a shape difference?

More time spent on thinning the dividers and a lot more time shaping. Plus I added a one inch spacer to give me more room

To radius the top.

What did you do to “update” your porting work? Is it a surface finish or a shape difference?

This was all done with the more aggressive burs I got from Killer Carbide in my last order. The finish will stay just like it is.

TT5.9mag

Two atmospheres are better than one

More time spent on thinning the dividers and a lot more time shaping. Plus I added a one inch spacer to give me more room

To radius the top.

So the answer was both shape and surface finish. Thanks.This was all done with the more aggressive burs I got from Killer Carbide in my last order. The finish will stay just like it is.

Well I started gasket matching a Victor340 today and this is the one I posted about comparing a stock Super Victor against a stock Victor340. So after it’s done I’ll do a post with before and after porting numbers from both intakes from the same head, same runner.

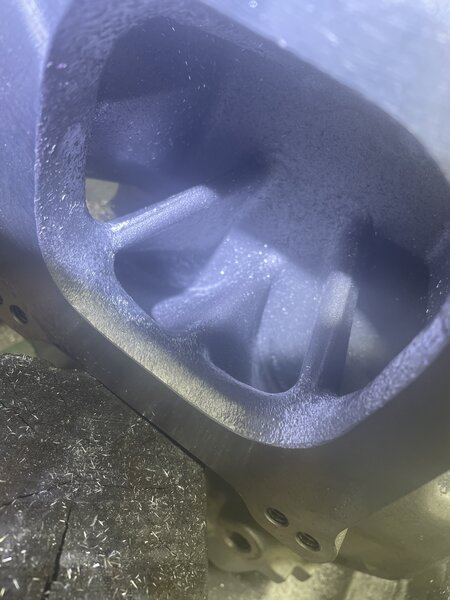

It’ll be interesting to see the plenum after you’re done with it compared to the before pics. That one looks to have some sharp edges

A lot of sharp edges. A Victor340 requires more work than a Super Victor.

It’ll be interesting to see the plenum after you’re done with it compared to the before pics. That one looks to have some sharp edges

I timed myself today and it’s hard to tell by these pictures but that lip is probably the worst I’ve ever dealt with on a Victor340 intake. On both drivers side and passenger side of the intake that lip that needed removed was close to 1/4 inch. 1/8-3/16 front and back. It took 20 minutes of very aggressive non stop grinding to remove that lip and just start radiusing the runner. Here’s some before pictures.

This is 20 minutes of hard grinding after. This is the 1/2 inch coarse but I used and thank God I have three of these rechargeable headlamps. Now I can start thinning and shaping the dividers and blend and great my desired shapes.

Was that lip just a casting flaw? Or a parting line from the mold? Edlebrocks finish work seems to be getting worse.

It’s always there so it’s just their parting line. There was zero “finish work” and never was on these intakes. I would never run one out of the box. At least the bolt holes and runners line up so I won’t complain. I can address everything else. I’d be curious to see the difference in flow right now but not curious enough to take the time to clean it up and flow it. To much work and to little time before race season.

Early quit today. This boys hands are beat up and in need of a Sicilian pizza. Got some rough shaping done.

Looking good. I've got a Victor 340. Hmmm.

Bobzilla

Well-Known Member

Sicilian pizza on pie day. Good call.Early quit today. This boys hands are beat up and in need of a Sicilian pizza.

I like the work on the manifold, but I'd really like a picture of the pizza.

-