71dustar

Well-Known Member

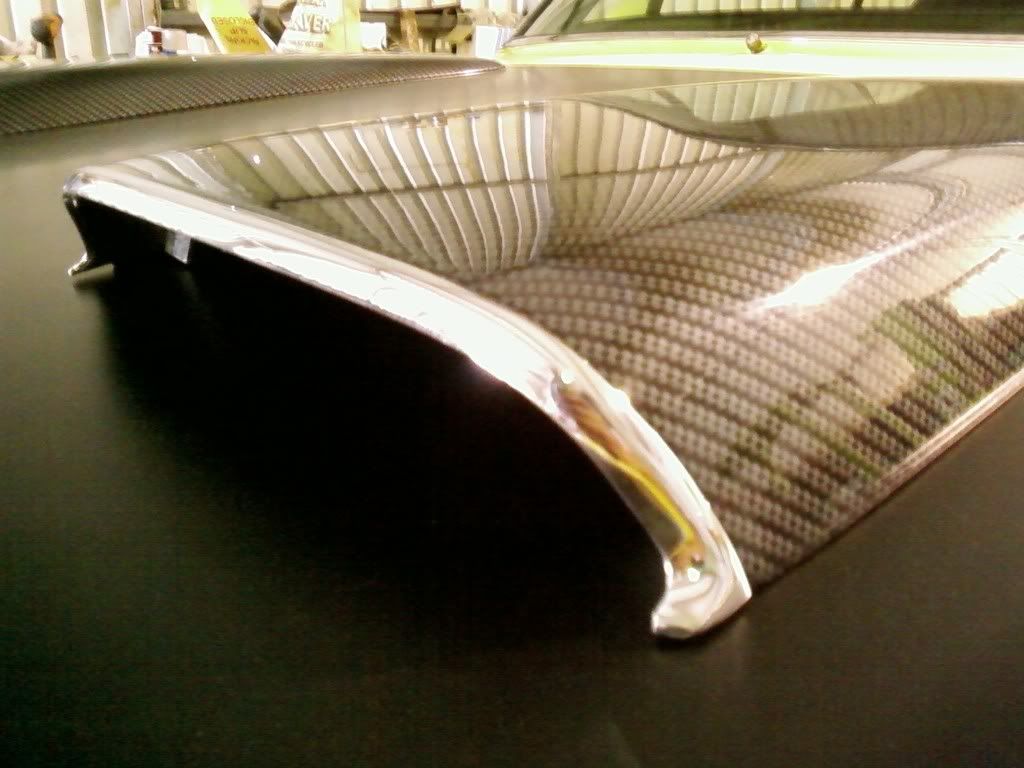

My girlfriends brother and i are going to try to wrap some interior parts with carbon fiber to see how it comes out and maybe do the whole interior. anyone use or have cf on their cars?

You can have pretty much anything wrapped in c/f.

Does any one make real C/F body parts for old cars? I have only seen new cars with them. If so. Who? If not why not if they are so light weight? Are they a lot lighter than fiberglass and are they more expensive? I don't like the look of C/F but if they are realy that light I would get some. Though I would paint them.

I would love to get some of that to do like a trim on my custom painted door panels that i make to sale.Im also considering making some dash faces,like rockymountain dashes had,but mine wont be aluminum,prob lexan.Also,i hear from the tuner guys i paint for,theres a carbon fiber shortage right now.Theyve been having trouble getting there parts that they ordered,because the companies that make them,can get carbon fiber,TRUE carbon fiber.I dont know if its true or not,but thats what ive been told.Maybe one of you guys know for sure.There was a company that came out with real carbon fiber six pack hoods for the A12 Road Runners and Super Bees a while back. I dont ever see any of the hood around though so maybe they didn't take off.

WOW! :cheers:

Where in the world do you get this stuff?! I have Corbeau bucket seats going into my Scamp that have carbon fiber-look vinyl, and a Redline Gauges gauge pod that also LOOKS like carbon fiber, but I've never seen anything like those valve covers/intake, or the door panels/kick panels. This stuff would be perfect for my car! I've GOTTA find out where this comes from...