jcarr210

Well-Known Member

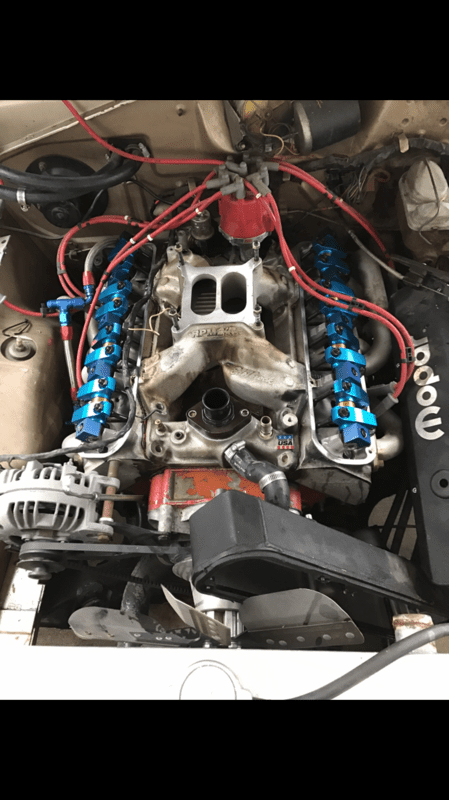

Just like it says everything is off everything is removed I just can't break it loose. I had a decent oil pooling on top of the intake and need to swap the gaskets but beating on it with a rubber mallet has done nothing. Intake and heads are both aluminum and I don't want to risk screwing anything up. Any advice would be appreciated. Thanks!