draginmopars

Well-Known Member

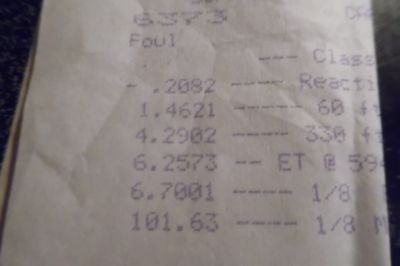

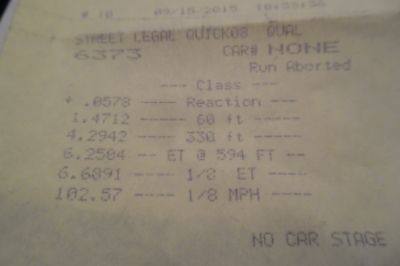

Finally quit raining on race night

So, took a break from working on the 72 dart.

Took the 70 more door to the track

have been running 6.84 @ 30* timing

Decided to bump the timing to 34*

95*.... track temp 130*

spinning the tires> new 325-50 x 15

let air down more to 16lbs

buddy says still spinning/smoking the right rear/ half track

I say NO Way> spool

car has slowed to 7.13

I thought it was due to the hot outside temp/ track

next pass

smoke pours out of the car, at the end of the track

load up go home

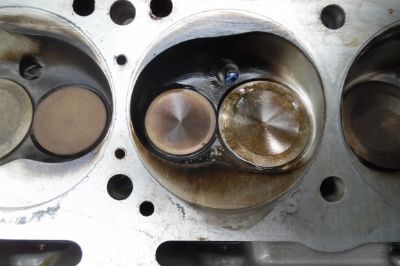

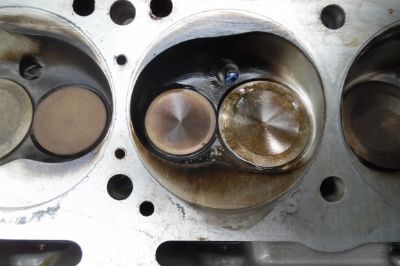

pull plugs... right side # 4 don't look good> oil

pulled the valve cover still can't see anything

next morning, pull the head

at least it wasn't a piston

#6 was also pushing the gasket

Felpro 1008

didn't hurt the head

still gonna make a very light cut to be sure it's flat

Wonder if I should go to a MLS head gasket

comp is 14-1

running E85

Break time is over

Time to pull the other side

also while the heads are off

gonna verify the timing mark is correct on the balancer

So, took a break from working on the 72 dart.

Took the 70 more door to the track

have been running 6.84 @ 30* timing

Decided to bump the timing to 34*

95*.... track temp 130*

spinning the tires> new 325-50 x 15

let air down more to 16lbs

buddy says still spinning/smoking the right rear/ half track

I say NO Way> spool

car has slowed to 7.13

I thought it was due to the hot outside temp/ track

next pass

smoke pours out of the car, at the end of the track

load up go home

pull plugs... right side # 4 don't look good> oil

pulled the valve cover still can't see anything

next morning, pull the head

at least it wasn't a piston

#6 was also pushing the gasket

Felpro 1008

didn't hurt the head

still gonna make a very light cut to be sure it's flat

Wonder if I should go to a MLS head gasket

comp is 14-1

running E85

Break time is over

Time to pull the other side

also while the heads are off

gonna verify the timing mark is correct on the balancer