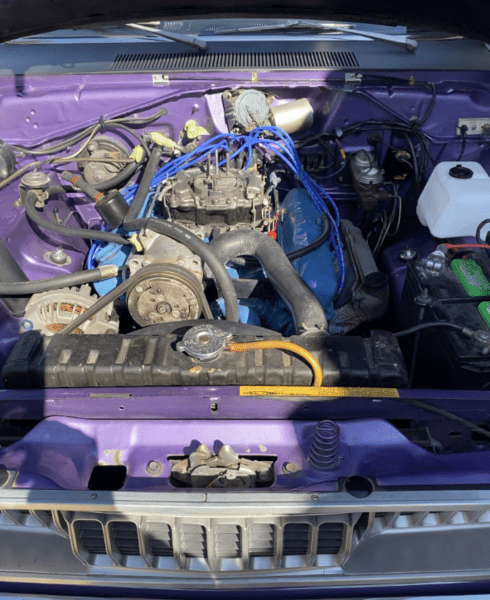

This is a Factory AC car, that at some point got converted to R134 and a Sanden 508 compressor was added to it. When I bought this car the AC was not working, and it was easy to see why. One of the hoses going from the compressor to the firewall had failed at the crimp on one of the end fittings, so it would not hold refrigerant. Not having the correct AC tools to crimp AC hoses, I just took the hose to a local AC shop and they made me a new one.

I am by no means an AC guy, my AC experience comes from removing them from most previous vehicles I had: "because race car"... Anyways, I have the AC gauges, the vacuum pump, oil injector, I have an AC flush kit, I have ester oil with dye, I bought a new drier and expansion valve and I am ready to put this back together and charge it. My concern is that when I took out the hose the oil that was in there was pretty black. I don't know how much oil was in that hose, so I have no idea how much oil was lost from the system, but I suspect that there wasn't much. I assume that there is some oil in the drier too, so when I change it I should add a bit for that.

From what I have been able to find, a Sanden 508 uses 6 ounces of oil when new with an AC system that has no oil. If I just removed that hose, the drier, and the expansion valve maybe add 1/2 of an ounce of oil? The old oil is kind of dirty and I am unsure if I should just flush the whole thing and put new oil. This AC compressor was added to the car about 20 years ago, but I doubt that it was used much. I would very much like to see what the AC guys here suggest I do.

I am by no means an AC guy, my AC experience comes from removing them from most previous vehicles I had: "because race car"... Anyways, I have the AC gauges, the vacuum pump, oil injector, I have an AC flush kit, I have ester oil with dye, I bought a new drier and expansion valve and I am ready to put this back together and charge it. My concern is that when I took out the hose the oil that was in there was pretty black. I don't know how much oil was in that hose, so I have no idea how much oil was lost from the system, but I suspect that there wasn't much. I assume that there is some oil in the drier too, so when I change it I should add a bit for that.

From what I have been able to find, a Sanden 508 uses 6 ounces of oil when new with an AC system that has no oil. If I just removed that hose, the drier, and the expansion valve maybe add 1/2 of an ounce of oil? The old oil is kind of dirty and I am unsure if I should just flush the whole thing and put new oil. This AC compressor was added to the car about 20 years ago, but I doubt that it was used much. I would very much like to see what the AC guys here suggest I do.