Hyper_pak

Old School Chrysler Fan

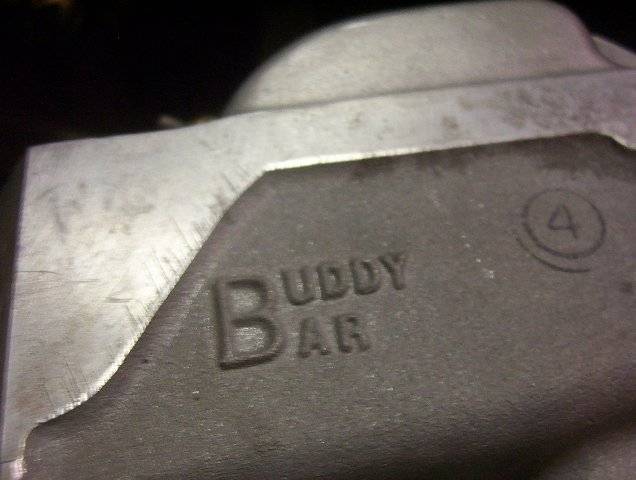

We have had this discussion on a couple of different threads. The first picture is the bottom of an STR-12 small block cross ram.

The second is a 289-302 Ford Intake.

The third is the bottom of a Weiand 2x4 small block intake.

I assume the BB on the Weiand is Buddy Bar.

If that is true, this company produced a lot of intakes for quite a few companies.

Is there a BB mark on the bottom of an STR-14?

Or any other intakes?

From Hot Rod Magazine.

"That's another thing about John (Fell). His grandfather started Buddy Bar Castings in South Gate, California. Buddy Bar does aluminum sand casting, and for decades did all the Ford Cobra aluminum castings as well as Edelbrock's before they went in-house in the late-1980's.

The second is a 289-302 Ford Intake.

The third is the bottom of a Weiand 2x4 small block intake.

I assume the BB on the Weiand is Buddy Bar.

If that is true, this company produced a lot of intakes for quite a few companies.

Is there a BB mark on the bottom of an STR-14?

Or any other intakes?

From Hot Rod Magazine.

"That's another thing about John (Fell). His grandfather started Buddy Bar Castings in South Gate, California. Buddy Bar does aluminum sand casting, and for decades did all the Ford Cobra aluminum castings as well as Edelbrock's before they went in-house in the late-1980's.