Flying G

Active Member

Greetings. I'm building up a 360-based 410 for an A-body with a manual transmission, mostly for street duty. This is a project my father started before he passed. He had collected up a lot of parts, including a DC mechanical cam P4120653 (284 deg adv duration, .528 in. lift), which I'd still like to use.

1st problem: The cam has been sitting for a few decades & has some rust spots on it. My machinist told me to run it & not worry about it, but I'd like y'all's opinion.

>> Is this still OK to use? >> What's the best way to clean it up?

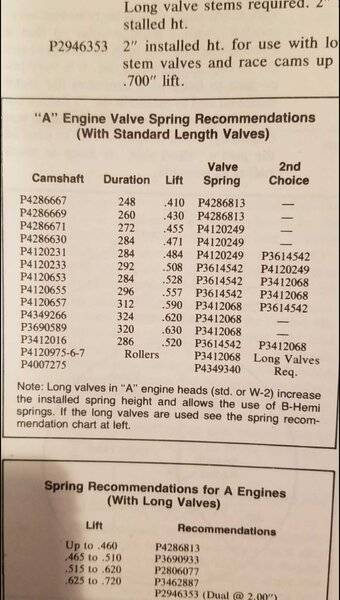

2nd Problem: The valve spring Mopar recommends for this cam, P3614542, doesn't seem to be available anymore. The "2nd choice" spring, P3412068 is still available, but seems to be more of a max-effort spring for lifts up to .630 in. Mopar never gave spring rates or pressures. I also need valves, retainers, etc., so I called Mancini for a quote. They spec'd Comp Cams spring 995-16 with a spring rate of 402 lb/in., which is the strongest spring listed on their website. That, too, seems like overkill.

>> Based on the cam specs & application, what's the right valve spring?

>> Is anyone else running this cam? What springs are you using?

Thanks for the help!

1st problem: The cam has been sitting for a few decades & has some rust spots on it. My machinist told me to run it & not worry about it, but I'd like y'all's opinion.

>> Is this still OK to use? >> What's the best way to clean it up?

2nd Problem: The valve spring Mopar recommends for this cam, P3614542, doesn't seem to be available anymore. The "2nd choice" spring, P3412068 is still available, but seems to be more of a max-effort spring for lifts up to .630 in. Mopar never gave spring rates or pressures. I also need valves, retainers, etc., so I called Mancini for a quote. They spec'd Comp Cams spring 995-16 with a spring rate of 402 lb/in., which is the strongest spring listed on their website. That, too, seems like overkill.

>> Based on the cam specs & application, what's the right valve spring?

>> Is anyone else running this cam? What springs are you using?

Thanks for the help!