dibbons

Well-Known Member

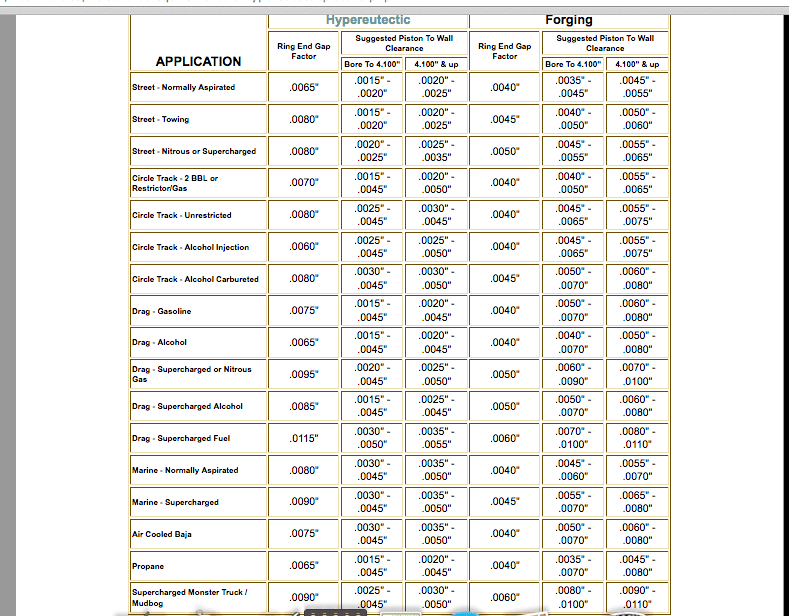

I have been searching and searching for some literature/manual/guide to help me decide on the proper piston skirt clearance for a NOS set of old school TRW dome forged piston. Today, I finally found a chart on the Hughs Engines website that might help me make the correct choice. Chart shows street as .0035" to .0045" and drag is .005" to .007 for bores up to 4.100". This will be a street car with occasionally drag strip time runs (for fun).

Last edited: