You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DID SOMETHING SILLY STR12 INTAKE LOL

- Thread starter cawley

- Start date

-

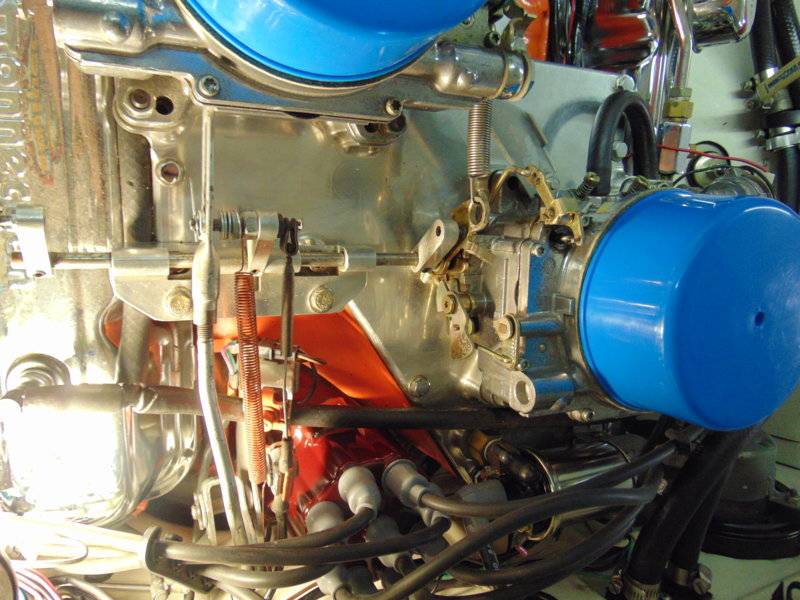

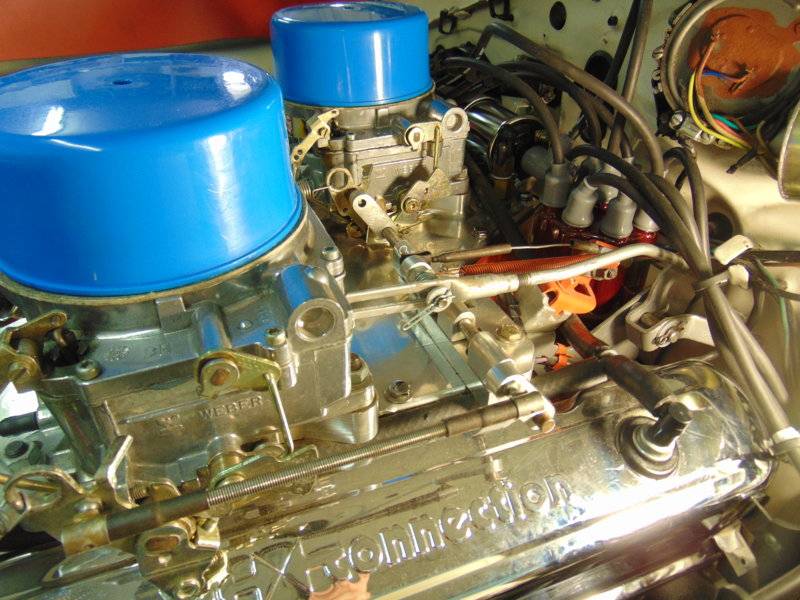

For the OP: The puddling issue is no joke. When I got my STR12 the top had been repaired twice. I found a billet CNC top at the nats in 2004 but the goys that made them don't have anymore (I tried to buy an extra). Contrary to what has been said here, I took another STR12 user's advice and had the modifications in the Direct Connection motor book done inside the manifold. That seems to have solved the puddling issue for me. I drive this as a street car. I'm using 2 500 Edelbrock AFBs both with chokes (this ain't an in line 2x4 set up and for the most part each carb feeds 4 cylinders, so setting up the carbs different means different mix for the cylinders on each side). As stated previously it is one cold natured set up - be prepared to let it come up to operating temp by the temp gauge before you take off. Once it's warm it works like a dream. They told me I couldn't run this on the street but after 15 years and 20,000 miles I beg to differ! Around town and on the highway for 4-500 mile road trip no problem. If I were replacing my carbs or starting fresh, I think I would try the new Edelbrock AVS II 500s for better atomization. I stuck in a photo that shows the inside of the manifold for the guys asking about how it works as far as runners. If you are running an automatic the linkage is a bit more complicated. This shows how we fabbed my linkage - I can post more linkage photos if it helps.

I would be interested in some photos of the linkage if you have them. If a guy doesn't come through for me I will have to make my own linkage. Yours is awesome looking. By the way did you have mod your hood or does it fit under? ThanksFor the OP: The puddling issue is no joke. When I got my STR12 the top had been repaired twice. I found a billet CNC top at the nats in 2004 but the goys that made them don't have anymore (I tried to buy an extra). Contrary to what has been said here, I took another STR12 user's advice and had the modifications in the Direct Connection motor book done inside the manifold. That seems to have solved the puddling issue for me. I drive this as a street car. I'm using 2 500 Edelbrock AFBs both with chokes (this ain't an in line 2x4 set up and for the most part each carb feeds 4 cylinders, so setting up the carbs different means different mix for the cylinders on each side). As stated previously it is one cold natured set up - be prepared to let it come up to operating temp by the temp gauge before you take off. Once it's warm it works like a dream. They told me I couldn't run this on the street but after 15 years and 20,000 miles I beg to differ! Around town and on the highway for 4-500 mile road trip no problem. If I were replacing my carbs or starting fresh, I think I would try the new Edelbrock AVS II 500s for better atomization. I stuck in a photo that shows the inside of the manifold for the guys asking about how it works as far as runners. If you are running an automatic the linkage is a bit more complicated. This shows how we fabbed my linkage - I can post more linkage photos if it helps.View attachment 1715483517View attachment 1715483520 View attachment 1715483518

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,245

- Reaction score

- 12,242

As I posted in my own str-12 thread, the way I did linkage was simple, I just used 2 lokar throttle cable assembly's, one on each throttle body, and modified the gas pedal to except both cables. Just a idea, it worked for me.

I'll take some specific shots for you and send them. A friend of mine did most of the fabrication. The key was to have the shaft perfectly aligned with the shaft through the back carb, with a hole in the arm for the throttle connection so the arm just slides over the ball in the throttle. You'll see when you see the pics. it eliminated a lot of joints and connections on that side making the whole system have less slop than the original. Are you running an automatic with a kickdown lever??

The air cleaners are REALLY close. I looked for the most filter surface with the least height. These are available from almost any performance parts place and these days they have a K&N filter in them. We had to mill off some material from the flange around the cleaner base where it fits onto the carb, but not so much that the base then hits stuff on the top of the carb. If you go with these I've got a bunch of extra stickers to go on them if you like them. I tried some drop base round ones, but by the time they were small enough not to hit each other, I was unhappy with the size of the filter element.

The air cleaners are REALLY close. I looked for the most filter surface with the least height. These are available from almost any performance parts place and these days they have a K&N filter in them. We had to mill off some material from the flange around the cleaner base where it fits onto the carb, but not so much that the base then hits stuff on the top of the carb. If you go with these I've got a bunch of extra stickers to go on them if you like them. I tried some drop base round ones, but by the time they were small enough not to hit each other, I was unhappy with the size of the filter element.

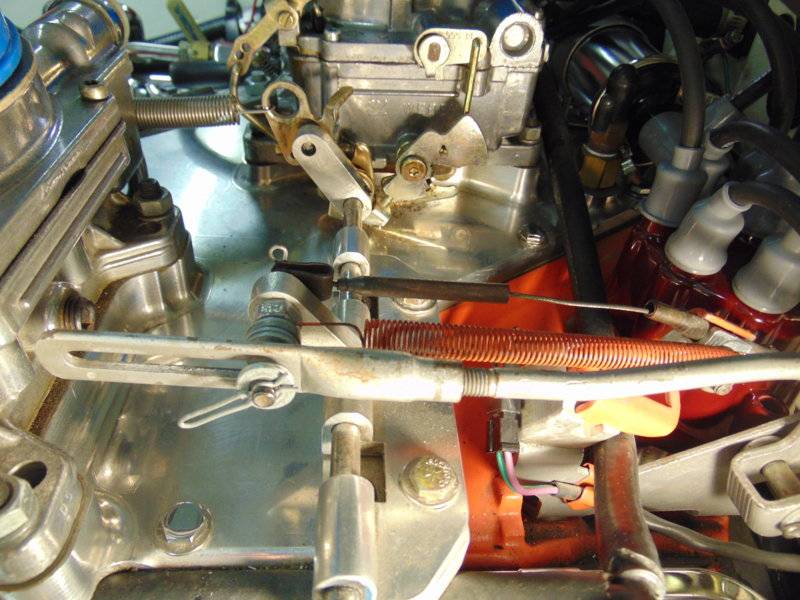

Here are linkage pics. I tried to get as many angles as I could. Some things to notice:

There is only one adjustment between the carbs on the rod from the shaft and arm to the forward carb throttle by a fine threaded rod with left and right hand connections to balls. You have to significantly raise the throttle cable hold down - I did this with a machined block that screws onto the original stud, with a new stud on top for the hold down, and then used a horizontal to vertical adapter that is stock Chrysler for a cruise control. This way you can use a stock throttle cable and hardware for the kickdown, though there is some pretty fancy bending of the adjustable arm to the original carb stud (now with its own arm on the shaft).

While I was taking pics, I remembered another detail - to have sufficient vacuum to the PCV valve I had to use the vacuum port on both carbs, plumb them togethr and then attach to the PCV (otherwise it's like half vacuum and resulting oil leaks).

There is only one adjustment between the carbs on the rod from the shaft and arm to the forward carb throttle by a fine threaded rod with left and right hand connections to balls. You have to significantly raise the throttle cable hold down - I did this with a machined block that screws onto the original stud, with a new stud on top for the hold down, and then used a horizontal to vertical adapter that is stock Chrysler for a cruise control. This way you can use a stock throttle cable and hardware for the kickdown, though there is some pretty fancy bending of the adjustable arm to the original carb stud (now with its own arm on the shaft).

While I was taking pics, I remembered another detail - to have sufficient vacuum to the PCV valve I had to use the vacuum port on both carbs, plumb them togethr and then attach to the PCV (otherwise it's like half vacuum and resulting oil leaks).

thank you for the pics I will be running a manual valve body the intake is going on a 408 I have to decide what for carbs I want to runHere are linkage pics. I tried to get as many angles as I could. Some things to notice:

There is only one adjustment between the carbs on the rod from the shaft and arm to the forward carb throttle by a fine threaded rod with left and right hand connections to balls. You have to significantly raise the throttle cable hold down - I did this with a machined block that screws onto the original stud, with a new stud on top for the hold down, and then used a horizontal to vertical adapter that is stock Chrysler for a cruise control. This way you can use a stock throttle cable and hardware for the kickdown, though there is some pretty fancy bending of the adjustable arm to the original carb stud (now with its own arm on the shaft).

While I was taking pics, I remembered another detail - to have sufficient vacuum to the PCV valve I had to use the vacuum port on both carbs, plumb them togethr and then attach to the PCV (otherwise it's like half vacuum and resulting oil leaks).View attachment 1715483998 View attachment 1715483999 View attachment 1715484000 View attachment 1715484001 View attachment 1715484002 View attachment 1715484003 View attachment 1715484004 View attachment 1715484006 View attachment 1715484007

View attachment 1715484009

I think when mine need replaced I'm gonna try the new AVS II from Edelbrock

Hyper_pak

Old School Chrysler Fan

Found an older posting (Nov 21, 2018) here on FABO where you asked the same question and apparently it was the foundry that did castings for Edelbrock and Shelby as well.

I found what I was looking for from Hot Rod Magazine.

Information.

"That's another thing about John (Fell). His grandfather started Buddy Bar Castings in South Gate, California. Buddy Bar does aluminum sand casting, and for decades did all the Ford Cobra aluminum castings as well as Edelbrock's before they went in-house in the late-1980's."

A56

Street Survivor

Just got around to reading this, thanx.For the OP: The puddling issue is no joke. When I got my STR12 the top had been repaired twice. I found a billet CNC top at the nats in 2004 but the goys that made them don't have anymore (I tried to buy an extra). Contrary to what has been said here, I took another STR12 user's advice and had the modifications in the Direct Connection motor book done inside the manifold. That seems to have solved the puddling issue for me. I drive this as a street car. I'm using 2 500 Edelbrock AFBs both with chokes (this ain't an in line 2x4 set up and for the most part each carb feeds 4 cylinders, so setting up the carbs different means different mix for the cylinders on each side). As stated previously it is one cold natured set up - be prepared to let it come up to operating temp by the temp gauge before you take off. Once it's warm it works like a dream. They told me I couldn't run this on the street but after 15 years and 20,000 miles I beg to differ! Around town and on the highway for 4-500 mile road trip no problem. If I were replacing my carbs or starting fresh, I think I would try the new Edelbrock AVS II 500s for better atomization. I stuck in a photo that shows the inside of the manifold for the guys asking about how it works as far as runners. If you are running an automatic the linkage is a bit more complicated. This shows how we fabbed my linkage - I can post more linkage photos if it helps.View attachment 1715483517View attachment 1715483520 View attachment 1715483518

A56

Street Survivor

My plan is to run an air filter set up like the Z-28, if you have time could you give me a measurement of the distance between the two air cleaner wingnut bolts? Thank you.I'll take some specific shots for you and send them. A friend of mine did most of the fabrication. The key was to have the shaft perfectly aligned with the shaft through the back carb, with a hole in the arm for the throttle connection so the arm just slides over the ball in the throttle. You'll see when you see the pics. it eliminated a lot of joints and connections on that side making the whole system have less slop than the original. Are you running an automatic with a kickdown lever??

The air cleaners are REALLY close. I looked for the most filter surface with the least height. These are available from almost any performance parts place and these days they have a K&N filter in them. We had to mill off some material from the flange around the cleaner base where it fits onto the carb, but not so much that the base then hits stuff on the top of the carb. If you go with these I've got a bunch of extra stickers to go on them if you like them. I tried some drop base round ones, but by the time they were small enough not to hit each other, I was unhappy with the size of the filter element.

11 1/16 between the center of the stud holes. This is as close as I can tell in that on the car it's kinda hard to get above them and see both ends of the tape at the same time. If you find something that works out please let me know. I have never been 100% satisfied with what I have in terms of looks.

A56

Street Survivor

I've always been fond of the cross ram a/c on the Z. I wanted something different than you see on our STR-12's. Once I gather up the carbs and mount them I'll be able to determine the plan. Thanks for taking the time to get the measurements. I'll keep you in mind as I move forward.11 1/16 between the center of the stud holes. This is as close as I can tell in that on the car it's kinda hard to get above them and see both ends of the tape at the same time. If you find something that works out please let me know. I have never been 100% satisfied with what I have in terms of looks.

A56

Street Survivor

Marcohotrod is a troll lmao why would you disagree with a question?My plan is to run an air filter set up like the Z-28, if you have time could you give me a measurement of the distance between the two air cleaner wingnut bolts? Thank you.

View attachment 1715488014

There is a guy here in the Seattle area that had an STR-12 on his made 70 Dart Convertible who made an air cleaner base that took a lid like a 6 pack lid that sat diagonal. I'll see if I've got a picture.

A56

Street Survivor

Mancini had one of these cross ram air cleaners on his Hemi Dart, also for 64-65 Hemi Super Stock A990 and A864There is a guy here in the Seattle area that had an STR-12 on his made 70 Dart Convertible who made an air cleaner base that took a lid like a 6 pack lid that sat diagonal. I'll see if I've got a picture.

So I finally ran across information on Frankendart (70 Dart Convertible made from a late 60s Dart). There is a picture here of the aircleaner he fabbed up using a factory oval aircleaner. http://www.cardomain.com/ride/2297182/1970-dodge-dart/

A56

Street Survivor

and that is one cool car as wellSo I finally ran across information on Frankendart (70 Dart Convertible made from a late 60s Dart). There is a picture here of the aircleaner he fabbed up using a factory oval aircleaner. http://www.cardomain.com/ride/2297182/1970-dodge-dart/

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,245

- Reaction score

- 12,242

In case any of you guys wanted to see my solution to not running the mechanical linkage, this is a 4 speed, so no trans kickdown linkage to worry with either.

replicaracer 43: tell us more about the car and the engine!

yes please doreplicaracer 43: tell us more about the car and the engine!

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,245

- Reaction score

- 12,242

I have a "build thread" on the engine setup somewhere on here, but it was in a 70 duster, now it's in a dart I have owned for a few decades. Short rundown, 410 cubic inch R3 stroker, edelbrock heads, 509 hyd cam, str-12 intake, dual QF 450s

A56

Street Survivor

Have you refined it some or is this the actual completed look and operation?In case any of you guys wanted to see my solution to not running the mechanical linkage, this is a 4 speed, so no trans kickdown linkage to worry with either.View attachment 1715499149

-

Similar threads

- Replies

- 21

- Views

- 3K

- Replies

- 7

- Views

- 1K

- Replies

- 8

- Views

- 500