How do we know? You've still not given one single number in regards to degreeing the camshaft. All you've said is "dot to dot". That's not degreed.So I degreed the crank initially. Sent it back due to errors. Verified ICL on replacement and installed timing dot to dot. Would this not be correct?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disappointing dyno results

- Thread starter jawbone

- Start date

-

Does your guy really know how to run a dyno? What standards did he correct to? There are SO many variables here it's pathetic. I can run a dyno and make a stock 318 show 500HP. So there's THAT. lolThanks for the words of wisdom. I'm leaning in that direction.

Sounds like you need a new dino man not a smaller carb. The engine will only use as much air flow as it needs. You can put a thousand CFM carburetor on that motor if it needs 600 it's only going to draw 600. Now I'd try a different carburetor sounds like that one was rebuilt screwy.No it's a flat tappet. Do I need a smaller carb?

Hi Rob. He can run a dyno. Was trying to correct for A/F ratio. He only had a bigger carb than mine. Test results were not much different.Does your guy really know how to run a dyno? What standards did he correct to? There are SO many variables here it's pathetic. I can run a dyno and make a stock 318 show 500HP. So there's THAT. lol

Dartfreak75

Restore it, Dont part it!

Couple questions for the op I haven't read all four pages so this may have been covered already @jawbone why ls it to late to change cams? If the engine isn't in the car yet it's not that difficult. We can help you pic the right cam for your combo and you won't be in the same boat. What is the rest of the engine components? I know you have stock intake and carb but what pistons, rods, crank bore etc? Have the heads had any work? What valve size and springs? Have you done a cylinder pressure test on the cylinders? The carb would be the last thing I'd be looking at at this point! I agree with the rest that cam is way wrong for making hp! If you don't care about hp or are dead set on not changing the cam. It will probably make a good daily driver! Just know that it's gonna be a 318 at heart. That cam is on par with 2bbl 318 cams

mopowers

Well-Known Member

You don't need to change carburetors to change AFR. You just have to TUNE the one you' got. Verify cam timing with an actual degree wheel and find a new dyno operator.Hi Rob. He can run a dyno. Was trying to correct for A/F ratio. He only had a bigger carb than mine. Test results were not much different.

Hi dartfreak75. Thanks for the inquiry. So much time and effort went into this build I am truly depressed with the results. At the moment have lost all momentum to continue. I am a very detailed person by nature. It's not that it's difficult to disassemble the engine; quite easy. It's the degree of perfection that went into putting it together. The pistons are JE brand .030 over. Know nothing regarding rods other than not stock. Assembly was balanced. Big valve "O" heads all stock. Cylinder pressure test = 150-160 psi. Was building a driver but at least expected to get stock performance. Would truly appreciate help in selecting a cam. Contacted Oregon Cam Grinding regarding replacement. There is word they have specs for 68 340 4 speed cam. They don't but reported people happy with approximate duplicate. If I do this means I have to drag engine back inside office including engine hoist and stand. Prep is a killer.Couple questions for the op I haven't read all four pages so this may have been covered already @jawbone why ls it to late to change cams? If the engine isn't in the car yet it's not that difficult. We can help you pic the right cam for your combo and you won't be in the same boat. What is the rest of the engine components? I know you have stock intake and carb but what pistons, rods, crank bore etc? Have the heads had any work? What valve size and springs? Have you done a cylinder pressure test on the cylinders? The carb would be the last thing I'd be looking at at this point! I agree with the rest that cam is way wrong for making hp! If you don't care about hp or are dead set on not changing the cam. It will probably make a good daily driver! Just know that it's gonna be a 318 at heart. That cam is on par with 2bbl 318 cams

65TerrorCuda

Well-Known Member

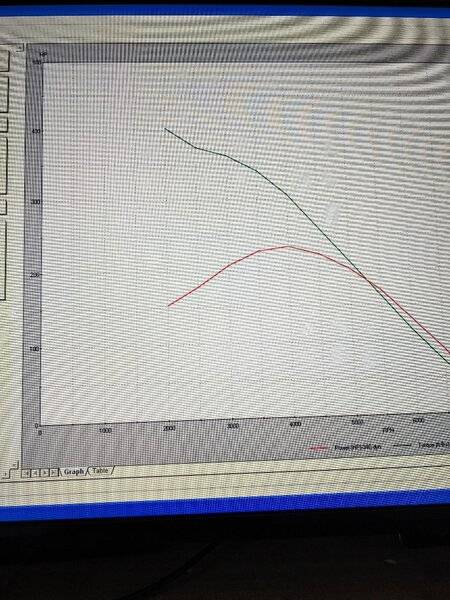

Well that's cool even if it's an awful curve. Shows just how screwed up it is.

What the OP may have done is not being expressed clearly here.

I have degreed cams that came in within the specs while also being at the "dot to dot" marks on the timing set. I have a Lunati solid in my Charger that met the 106 centerline with the timing marks at the "dot to dot" mark. At a glance, it might look like I took a short cut but if the intake centerline is where you want it and the timing marks line up with no additional work, that is great. What else do you do? I hear people suggest to degree the cam but rarely ever hear of what to do if the numbers are way off and how to correct it. I suppose a crank sprocket with multiple keyways is one method, one that is easiest and fastest. I've seen offset dowels but how does that help a guy with a 1 bolt cam?

The OP is clearly frustrated. I know that when I am that way, I don't always explain myself correctly. Anger and frustration have a way of clouding the brain and impeding the thought process.

I have degreed cams that came in within the specs while also being at the "dot to dot" marks on the timing set. I have a Lunati solid in my Charger that met the 106 centerline with the timing marks at the "dot to dot" mark. At a glance, it might look like I took a short cut but if the intake centerline is where you want it and the timing marks line up with no additional work, that is great. What else do you do? I hear people suggest to degree the cam but rarely ever hear of what to do if the numbers are way off and how to correct it. I suppose a crank sprocket with multiple keyways is one method, one that is easiest and fastest. I've seen offset dowels but how does that help a guy with a 1 bolt cam?

The OP is clearly frustrated. I know that when I am that way, I don't always explain myself correctly. Anger and frustration have a way of clouding the brain and impeding the thought process.

65TerrorCuda

Well-Known Member

Hp is climbing. You sure the dyno operator got the carb fully open?Well that's cool even if it's an awful curve. Shows just how screwed up it is.

Hi Kern Dog. I here ya brother. You are so right on!What the OP may have done is not being expressed clearly here.

I have degreed cams that came in within the specs while also being at the "dot to dot" marks on the timing set. I have a Lunati solid in my Charger that met the 106 centerline with the timing marks at the "dot to dot" mark. At a glance, it might look like I took a short cut but if the intake centerline is where you want it and the timing marks line up with no additional work, that is great. What else do you do? I hear people suggest to degree the cam but rarely ever hear of what to do if the numbers are way off and how to correct it. I suppose a crank sprocket with multiple keyways is one method, one that is easiest and fastest. I've seen offset dowels but how does that help a guy with a 1 bolt cam?

The OP is clearly frustrated. I know that when I am that way, I don't always explain myself correctly. Anger and frustration have a way of clouding the brain and impeding the thought process.

Dartfreak75

Restore it, Dont part it!

I understand your frustration and loss of momentum! Trust me I get it more than most! I ran into issues with dang near every step on mine and had to reconfigure my build several times. At one point I got so frustrated and overwhelmed it wasn't even fun anymore and walked away for almost a year! Then got right back at it and solved the issue in no time. When I say we are here to help I mean that! There is so many helpful and knowledgeable guys here that know by doing not just know by reading or youtube lol. I'm quite partial but I would really recommend a luniti voodoo 10200702 cam. I understand you not wanting to tear it back down I really get that. If it was mine I wouldn't want to either. I would probably slap it in the car and drive it and see what the car does. It may run better than you think and you will be happy with it. If it's a lazy slug and you can't stand to drive it because it's so boring you can swap the cam from inside the car.Hi dartfreak75. Thanks for the inquiry. So much time and effort went into this build I am truly depressed with the results. At the moment have lost all momentum to continue. I am a very detailed person by nature. It's not that it's difficult to disassemble the engine; quite easy. It's the degree of perfection that went into putting it together. The pistons are JE brand .030 over. Know nothing regarding rods other than not stock. Assembly was balanced. Big valve "O" heads all stock. Cylinder pressure test = 150-160 psi. Was building a driver but at least expected to get stock performance. Would truly appreciate help in selecting a cam. Contacted Oregon Cam Grinding regarding replacement. There is word they have specs for 68 340 4 speed cam. They don't but reported people happy with approximate duplicate. If I do this means I have to drag engine back inside office including engine hoist and stand. Prep is a killer.

We went down that path and yes made sure it was fully open. Good idea though.Hp is climbing. You sure the dyno operator got the carb fully open?

The cam that's in there now is very close to the stock cam, as several have said. Again, the duration numbers provided are at .050, not advertised duration, which is measured at something like .004 or .006. This motor would benefit from more cam, but it should make more power than it does with this cam.

You have to cc the cylinder with piston at TDC and add that to the combustion chamber area to get accurate CR.Thanks for the detailed and informative response. I did cc the heads and calculate compression ratio. cc=65.6 CR=9.687:1 This was based off graduated cylinder.

Engine builder said the same regarding intake valve timing. What I do not understand is why stock Mopar 340 intake is at -2 BTDC (@.050), Are you using the advertised value of 26. May be more mis-information.

Do you know what effect leaning A/F ratio will have on numbers.

View attachment 1716141700

When you have your cam set at 106 ICL, intake open point is measured at.006 for a mopar cam. Forget about what it is at.05. That is a measure of how fast the valve ramps up on the cam.

Jet your carb main jet so you have A/F slightly lean at cruising rpm. It should be slightly rich at WOT to make the most horsepower. I don’t know how to do that with a carter avs. You are too rich through out your power curve. Did the dyno operator change main jets and the metering rods?

What brand cam are you running and exactly how much horsepower are you looking to make?

Think I'm probably more than two years into this build. Much more than just a steep learning curve. It's like you said; overcoming the frustration that comes with it. I'm not just trying to repair or refurbish an existing engine, it's starting from scratch. Missing everything but the short block. Will say learned a lot and enjoyed most of it. Sure bought my share of parts that I will not use. I'll get over it and get back to it. I was so ready to get engine in car and start work on drivetrain. Don't think I have the strength install cam once engine is in the car. Between the weight of heads and intake manifold, too much for this old man. Thanks for the recommendation on voodoo cam. Will ad it to my new list. What do you have it in? Stock engine components?I understand your frustration and loss of momentum! Trust me I get it more than most! I ran into issues with dang near every step on mine and had to reconfigure my build several times. At one point I got so frustrated and overwhelmed it wasn't even fun anymore and walked away for almost a year! Then got right back at it and solved the issue in no time. When I say we are here to help I mean that! There is so many helpful and knowledgeable guys here that know by doing not just know by reading or youtube lol. I'm quite partial but I would really recommend a luniti voodoo 10200702 cam. I understand you not wanting to tear it back down I really get that. If it was mine I wouldn't want to either. I would probably slap it in the car and drive it and see what the car does. It may run better than you think and you will be happy with it. If it's a lazy slug and you can't stand to drive it because it's so boring you can swap the cam from inside the car.

Phreakish

Well-Known Member

What the OP may have done is not being expressed clearly here.

I have degreed cams that came in within the specs while also being at the "dot to dot" marks on the timing set. I have a Lunati solid in my Charger that met the 106 centerline with the timing marks at the "dot to dot" mark. At a glance, it might look like I took a short cut but if the intake centerline is where you want it and the timing marks line up with no additional work, that is great. What else do you do? I hear people suggest to degree the cam but rarely ever hear of what to do if the numbers are way off and how to correct it. I suppose a crank sprocket with multiple keyways is one method, one that is easiest and fastest. I've seen offset dowels but how does that help a guy with a 1 bolt cam?

The OP is clearly frustrated. I know that when I am that way, I don't always explain myself correctly. Anger and frustration have a way of clouding the brain and impeding the thought process.

If it's right on when dot-to-dot, that's great. If it's not, then a multi-keyway crank or cam sprocket or offset keys are the solution. They're not too difficult to obtain, and easy to install when doing the timing set.

If there's no good way to correct it, then at least it's a known. When there's no knowns and then something turns out not quite like expected, it makes it really tough to figure out what to do at that stage.

Don't rush to change things. Take your time and be methodical. Try another carb first or put that AVS on another car and see how it works.overcoming the frustration that comes with it.

Just reading through this and I was like "his cam is very close to a stock 340 cam".... one is advertised and one is @ 050 ... then I see RRR pointed that out...Yall are off the mark, IMO saying that cam isn't a good one. Yall are comparing advertised duration of the 340 cam to the .050" duration of the cam he has. You cannot do that. The .050" duration of the 340 cam was actually very close to what he has now. I doubt very seriously the cam is where the problem is.

Carb is not too big.

Hi ch1ll. Regarding Carter AVS. Dyno operator only had a lager Holley which yielded similar results. He will receive 600cfm Holley for pull tomorrow if weather permits. Humidity is currently high. Operator does not have any replacement jets or metering rods. The Carter I had rebuilt was stock unit for 68 or 70 340 4 speed application. Can't remember which. Would only think jetting would be correct.You have to cc the cylinder with piston at TDC and add that to the combustion chamber area to get accurate CR.

When you have your cam set at 106 ICL, intake open point is measured at.006 for a mopar cam. Forget about what it is at.05. That is a measure of how fast the valve ramps up on the cam.

Jet your carb main jet so you have A/F slightly lean at cruising rpm. It should be slightly rich at WOT to make the most horsepower. I don’t know how to do that with a carter avs. You are too rich through out your power curve. Did the dyno operator change main jets and the metering rods?

What brand cam are you running and exactly how much horsepower are you looking to make?

Cam is from Camcraft. I know, you never heard of them. Wish I hadn't. Only looking to make stock horsepower. That's all I can expect using stock engine components.

Phreakish

Well-Known Member

I don't see it mentioned, maybe I missed it.

Any idea what kind of ignition timing your engine guy put into it? Any idea on the curve (idle/all-in/max timing and matching RPMs would help)?

Was TDC on the balancer confirmed?

The way the power and AFR jump around almost seems like intermittent misfire of some sort. Were you there when it ran? How'd it sound?

Any idea what kind of ignition timing your engine guy put into it? Any idea on the curve (idle/all-in/max timing and matching RPMs would help)?

Was TDC on the balancer confirmed?

The way the power and AFR jump around almost seems like intermittent misfire of some sort. Were you there when it ran? How'd it sound?

65TerrorCuda

Well-Known Member

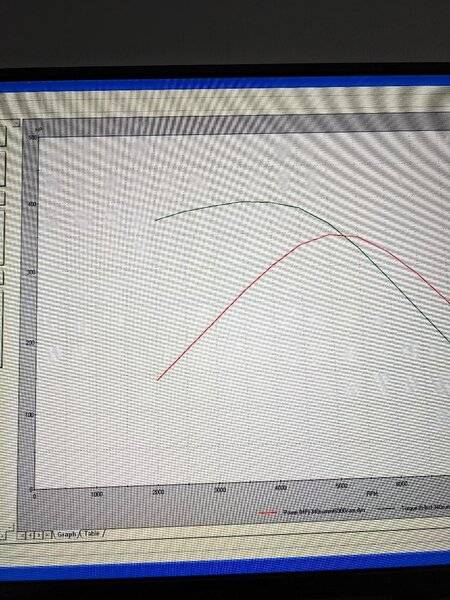

I just plugged a summit 6900 cam into a simulation vs yours and it's about 100 horse higher. I've got pics but they're ugly...

-

Similar threads

- Replies

- 85

- Views

- 8K

- Replies

- 24

- Views

- 4K

- Replies

- 45

- Views

- 9K