You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

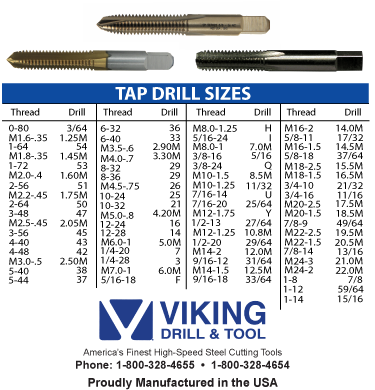

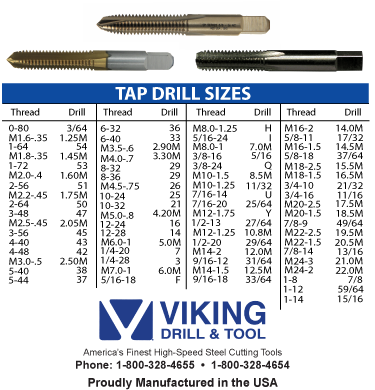

drill bit size

- Thread starter dart67

- Start date

-

3/8th what? By 16, by 24 what thread count?

My chart say 5/16ths

Use some penetrating oil or tap fluid when cutting the new threads.

Robbie2734

Lambcharger

Home Depot sells tap and drill bit as a package here, not too expensive and easier to get the right bit.

Home Depot sells tap and drill bit as a package here, not too expensive and easier to get the right bit.

Yes, but it's harder to find the pipe taps.

There are also different kinds of pipe taps. they have straight pipe taps and tapered pipe taps. You usually find the tapered pipe taps. Those are sensitive to how deep you run the tap as it is tapered. If you run it too deep, your part will run all the way through the part before reaching torque, then the hole is too big. With a tapered pipe tap, you have to go a few threads at a time and then check with the part. then maybe two or three threads more and recheck with the part again. Repeat as necessary.

If you can find a straight pipe tap, that is the better way to go. It doesn't open up the diameter of the hole where the mating part will not fit, like the tapered pipe taps can do.

Jus' fer "drill" LOL all you need to do is Google this. There are skilliouns of online tap charts

tap drill size:

https://www.google.com/search?num=4...8.0....0...1c.1.48.hp..7.8.1568.0.zfltje28Mis

tap drill size:

https://www.google.com/search?num=4...8.0....0...1c.1.48.hp..7.8.1568.0.zfltje28Mis

moe7404

moe7404

tap drill charts are all over the internet. some times if you are putting a 1/4 20 bolt in a place where strength is NOT critical drill a slightly over size hole. makes the taping easy. i think a #10 is called out. but use a 7/32 for easy taping. but you WILL lose some strength. do NOT do this when strength is needed.

lil red

Well-Known Member

tap drill charts are all over the internet. some times if you are putting a 1/4 20 bolt in a place where strength is NOT critical drill a slightly over size hole. makes the taping easy. i think a #10 is called out. but use a 7/32 for easy taping. but you WILL lose some strength. do NOT do this when strength is needed.

true...the chart (as well as the formula of thread dia. minus pitch =minor dia) is for 75% effective thread, drilling bigger helps for the larger taps (1 inch plus) but with small taps stick with recommended drill size and use fluid.....it taps the same.

GEO

Sarcasm Inc.

I have some taps that have what drill size to use engraved on them

What is irritating as all 'ell is when you go in somewhere looking for a "letter size" twist drill, and the pimply faced kid behind the counter tries to make like it's YOU that don't know

I have some taps that have what drill size to use engraved on them

I have Blue Point both standard and metric, both sets are like that, as well as a nice laminated chart with each set.

moe7404

moe7404

one time on a turret lathe i was making a hole for a 1 1/4 bolt. i used the reg chart. but after taping it. it didnt look like the thread was deep enough. so going off the formula in the book. did the math. and used a boring bar, instead of a drill. then it looked much better. from then on i only did it by the math. a program in my pocket computer made it very easy. if it wasnt for calculators and computers i would never have been able to be a machinist.

-

Similar threads

- Replies

- 15

- Views

- 1K