I’ve got a challenge for the group. I have a 440 with a modest tune 425HP in a 67 Dart GT convert. The engine compartment simply doesn’t have the capacity to dissipate the heat and the mechanical pump fails after 15-20 minutes. I mounted an electric pump over the rear axel and simply bypassed the mechanical pump. It works great and no issues except the mechanical pump is very loud. I’d like to eliminate. Ideally I’d like an in tank pump but everything out there seems tailored to fuel injection – 65 PSI versus the 5-7 PSI I need. Wondering what others have done to fix this issue. Thanks Steve

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric fuel system

- Thread starter Dartman61

- Start date

-

Not in tank, but one of the best designs ever made.

Carter P4600HP In-Line Electric Fuel Pump | Carter Carburetors, Parts & Rebuild Kits

Carter P4600HP In-Line Electric Fuel Pump Carter Fuel Systems universal fit Rotary vane pumps are internally regulated, offer a free flow design with no points to burn out or shaft seals to leak 12 volt 3/8 inch NPT inlet and outlet 6 - 8 psi output, 100 gph free flow Includes comprehensive...

www.cartercarburetor.net

coloradohill

Well-Known Member

I had a very similar issue ( electric fuel pump being noisy), and went with a Tanks inc. setup with multiple carbs. Just use a fuel pressure regulator and gauge to regulate the pressure and a return line for the fuel bled from the regulator and send it back to the tank. You will need to use their tank. The pump is almost unnoticeable.

Mopar Fuel Tanks

Mopar Fuel Tanks

Last edited:

OK to clarify - its my electric pump that is noisy. Its a Holly electric pump mounted on rubber to the body over the rear axel and it's noisy. Regards the suggestio the mechanical pump should work, I have used several mechanical pumps in the past and after about 15 minutes the heat on the engine compartment gets to a point that they lose seal and can't draw, - they vapor lock and engine stops. The only way to counteract is to use a electronic pusher pump and if your doing you might as well simply bypassed the mechanical pump. The mechanical pump is a Holly from Summitt and is at least the 3rd mechanical pump I've used. Frankly, if I could rely on the mechanical pump I'd scrap the electric setup but without the pusher the engine loses fuel after 15-20 minutes and is very hard to start (draw fuel up from tank). I appreciate the feedback so far - good stuff - Thanks

MidnightSwinger

Well-Known Member

If you are willing to change your pump, this one is about half as quiet as a Holley pump in my experience. Perfect for carbs.

Edelbrock 1791 Edelbrock Quiet-Flo Electric Fuel Pumps | Summit Racing

Edelbrock 1791 Edelbrock Quiet-Flo Electric Fuel Pumps | Summit Racing

TrailBeast

AKA Mopars4us on Youtube

Not in tank, but one of the best designs ever made.

[/URL][/URL]

I have that exact pump, and it’s a noisy little punk if mounted with what it comes with.

Those three little round grommets just don’t cut it.

I screwed a 3 inch long tube of radiator hose to the frame and bolted the pump to that.

It stands the pump off about 1.5 inches from the frame metal and quieted it down quite a bit.

Overall I think electric pumps are kind of a pain, but a fuel return with an electric pump in the AZ heat is worth it.

Quick starting and no vapor lock issues.

I don't understand the high under hood heat issue the OP is having. There are a raft of BBM powered A bodies out there without the heating problem. Maybe the OP could post pictures so we might see where possibly the problem is.

PRH

Well-Known Member

I’d be checking to see if the fuel pump rod is still the correct length.

Dcuda69

Well-Known Member

- Joined

- Jul 14, 2008

- Messages

- 261

- Reaction score

- 119

I agree 100%. I run a simple Carter style mech pump on my 470" street toy. Zero issues.I’d be checking to see if the fuel pump rod is still the correct length.

@TrailBeast did you bolt the pump to one side of the hose and the other side of the hose to the frame so that the pump is sorta hanging? For example, you could stick your fingers through the interior of the hose?

I may try that to quiet mine down. I bought a cam extension for my Magnum cam but haven't installed it yet. "While I'm in there" I want to replace the water pump hand harmonic balancer.

I may try that to quiet mine down. I bought a cam extension for my Magnum cam but haven't installed it yet. "While I'm in there" I want to replace the water pump hand harmonic balancer.

72Duster440

Well-Known Member

I had a very similar issue ( electric fuel pump being noisy), and went with a Tanks inc. setup with multiple carbs. Just use a fuel pressure regulator and gauge to regulate the pressure and a return line for the fuel bled from the regulator and send it back to the tank. You will need to use their tank. The pump is almost unnoticeable.

Mopar Fuel Tanks

That's the setup I run, although I have EFI. If you go this route, mount the regulator right by the gas tank, then you don't have to run a return line the entire length.

coloradohill

Well-Known Member

I was going to mount the regulator near the gas tank for that reason but they recommend having it as close to the carb as possible.

So I ran the return line and mounted a gauge at the regulator to have the ability to keep an eye on the pressure and adjust it easily.

It does require a little more work. But with a carb(s) I believe it’s worth it.

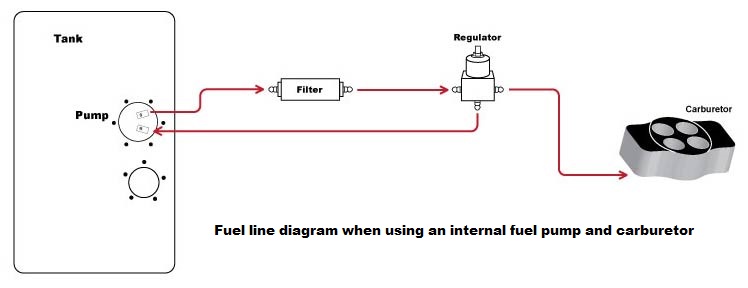

Feeding a Carbureted Engine with an EFI Fuel Pump

So I ran the return line and mounted a gauge at the regulator to have the ability to keep an eye on the pressure and adjust it easily.

It does require a little more work. But with a carb(s) I believe it’s worth it.

Feeding a Carbureted Engine with an EFI Fuel Pump

TrailBeast

AKA Mopars4us on Youtube

@TrailBeast did you bolt the pump to one side of the hose and the other side of the hose to the frame so that the pump is sorta hanging? For example, you could stick your fingers through the interior of the hose?

I may try that to quiet mine down. I bought a cam extension for my Magnum cam but haven't installed it yet. "While I'm in there" I want to replace the water pump hand harmonic balancer.

Exactly, and now I really only hear the pump until I start the car.

Not near as much through the body.

I also have a return that uses an orifice instead of a regulator.

It T’s off right at the carb inlet.

I temporarily put a pressure gauge inline to watch the fuel pressure as I tested the return orifice size to keep the pressure at 7 psi and still return fuel to the tank.

Last edited:

Wow great suggestions and feedback. I did try to quiet my pump by mounting on rubber hose as the Trail beast suggested. I used an 1 1/4 inch rubber pipe connector -see pics - unfortunately it didn't help much. Regards mechanical pump, I've never been able to keep the car running after it warms up. Once warm and turned off its very hard to start, just can't get the fuel up to the carb. The only way of overcome this to date is to use the electric pusher pump and if your going to do that why not eliminate the mechanicals pump? I would love to hear more thoughts on making the mechanical pump work. I'm attaching picks of the engine bay and mechanical pump as well.

Have you checked to make sure the fuel pump push rod is the correct length and that the lobe on the cam isn't worn down? I've run BBMs in every body type and never had the problem with mechanical fuel pumps that you are having.

Engine has less than 5,000 on it and was rebuilt with all new parts - so I'm confident about the cam. Where do I find proper length for the push rod? I'll do some research but if you already have a source it would be great if you would share. Thanks

Unfortunately, I no longer run BBMs, I've switched over to stroked SBMs in my bracket car. I'm sure someone here has the correct measurement for the push rod. You might want to ask the question in the "General" section.

Dcuda69

Well-Known Member

- Joined

- Jul 14, 2008

- Messages

- 261

- Reaction score

- 119

According to a listing I saw on Amazon and a thread I saw over at Moparts it should be 3.25"

Are you using any type of vapor return? It would require running a line back to the tank, but it works very well to cure vapor lock with mechanical pumps.

The factory used them on some 440s around 1969-'70. Repops are available by Goodmark, I think.

Also Wix makes a filter filter that will accomplish the same thing. I'm not sure this is the one. The one I remember had one nipple at a 90° angle to the others, but it gives you the idea.

https://www.oreillyauto.com/detail/...rator/6bf814fc80d2/wix-fuel-filter/wix0/33040

The factory used them on some 440s around 1969-'70. Repops are available by Goodmark, I think.

Also Wix makes a filter filter that will accomplish the same thing. I'm not sure this is the one. The one I remember had one nipple at a 90° angle to the others, but it gives you the idea.

https://www.oreillyauto.com/detail/...rator/6bf814fc80d2/wix-fuel-filter/wix0/33040

A quick update. I pulled the mechanical fuel pump yesterday and the push rod. I was shocked to find the rod was 2 3/4 inches and not the 3 1/4 inch. Everywhere I check indicates the push rod should be 3 1/4 inch. I've ordered up a new pushrod and will see if I can run on mechanical pump alone. You just can't assume the correct parts. I bought this engine complete and then had it rebuilt and somewhere along the line the pushrod was changed out. The car same with an electric pusher pump already installed so when I had trouble the easiest and quickest solution was to use the electric pump. I' gonna feel a little foolish if this works!

You can't fault yourself, you took someones word that everything was correct. But then again, I leave nothing to chance on my end. I go over everything with a fine toothed comb to try and make sure all is correct.

Update. I installed the correct pushrod for the fuel pump. It is able to maintain 6 PSI at the carb even with the electric pump in line and turned off. The real test will be this summer. If it goes well this summer I'll remove the electric pump entirely. I think I may also run a return line since that got some positive comments to help with vapor locking. Appreciate everyone's help.

-

Similar threads

- Replies

- 2

- Views

- 302

- Locked

[FOR SALE]

Edelbrock Electric Fuel Pump 1791 Quiet-Flo

- Replies

- 1

- Views

- 545

- Replies

- 26

- Views

- 2K

- Replies

- 43

- Views

- 2K