Less external connections? How? Even if you count the ignition box plug with the 4 it has as "external", which I do not, they are the same. Hot, ground and four connections. If you're using an HEI module on a Mopar with an external coil, you cannot count the coil connections, as the Mopar already had those. The only think that truly reduces the number of connections with HEI is the original coil in cap GM HEI distributor. Then all you have is ONE external 12v wire.Kern,

The GM HEI has less external connections/connectors that can become loose connections or corrode. So from that perspective alone, it is more reliable.

A measure of the ignition's ability to fire a big plug gap is testament to the design & for inductive ign systems, the HEI wins hands down & is better than the Chrys system for reasons stated in post #22. I have run 0.125" plug gaps with HEI ign. Made no difference that I could feel, but certainly no misfires to 5500 rpm. An engine that I tune for drag racing in a 4000 lb car [ without driver ] has run 11.65/118 mph with a 3.31 axle & TQ carb. It has the MSD HEI module, 0.070" plug gap with Iridium plugs & runs to 6500 rpm.

HEI dist are now made for engines that previously were never equipped with HEI, Fords, Holden Chrys etc. Note that NOBODY is making Chrys dists for GM, Ford, etc. There must be a reason for that.....

Manufacturers do not spend money upgrading ign systems unless they have to & when they do they are looking for a more powerful spark, not less.....

One manufacturer { I believe it was Honda } built an engine in the 1980s that had a separate mini combustion chamber that created a 'fire' to ignite the main chamber. They obviously thought bigger is better....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FBO's black HEI ignition box

- Thread starter moparlee

- Start date

-

RB,

What you fail to understand is that when you put that big cam in an engine & it runs rough at idle, the engine is misfiring. Even stock engines misfire but you do not notice/hear it. If you can reduce or eliminate misfiring, you make more power.

At idle & low speeds, a long duration spark is needed with a lot of heat in it. Inductive ign provides a long duration spark, ideal for the purpose. This is why modern engines use high energy systems with big plug gaps to run leaner mixtures & reduce emissions.

Try running points ign & 0.025" plug gaps on one of these engines....

From the Bosch Automotive Handbook: ' An ign spark energy of approx 0.2mj is adequate to ignite a stoichometric A/F mixture, while richer or leaner mixtures require substantially higher levels of spark energy'........'On the one hand, the electrode gap should be as wide as possible so that the spark reaches as large an air-fuel volume as possible & the mixture is rapidly & reliably ignited so that the engine runs smoothly'. ..........'It is frequently impossible to achieve smooth idle when the electrode gap is too narrow'.

Phil Jacobs, founder of Jacobs Ign Systems, claims 0.100" is the ideal spark plug gap.....

What you fail to understand is that when you put that big cam in an engine & it runs rough at idle, the engine is misfiring. Even stock engines misfire but you do not notice/hear it. If you can reduce or eliminate misfiring, you make more power.

At idle & low speeds, a long duration spark is needed with a lot of heat in it. Inductive ign provides a long duration spark, ideal for the purpose. This is why modern engines use high energy systems with big plug gaps to run leaner mixtures & reduce emissions.

Try running points ign & 0.025" plug gaps on one of these engines....

From the Bosch Automotive Handbook: ' An ign spark energy of approx 0.2mj is adequate to ignite a stoichometric A/F mixture, while richer or leaner mixtures require substantially higher levels of spark energy'........'On the one hand, the electrode gap should be as wide as possible so that the spark reaches as large an air-fuel volume as possible & the mixture is rapidly & reliably ignited so that the engine runs smoothly'. ..........'It is frequently impossible to achieve smooth idle when the electrode gap is too narrow'.

Phil Jacobs, founder of Jacobs Ign Systems, claims 0.100" is the ideal spark plug gap.....

RRR,

Maybe I should have been more specific with my poor/corroded connections comment. I meant any joint that is not soldered: removal plug/sockets, spade lugs etc.

There is no comparison using a HEI dist. With HEI there is NO bal resistor & the 4 spade lugs; there is no Nichrome wire that can burn out as in the Mopar bal res. The HEI pick up plugs directly into the module, so one connection. On the Mop ECU pick up, there are two connections: dist plug/skt & ECU plug/skt. The HEI coil has 3 connections, harness from the module to the coil & wire from the ign sw. The Mop system has 5 connections, ign sw to bal res, bal res to ECU, ECU to coil.

If you are using the HEI module you can mount/install it such that it has less connection points than the std Mop ECU set up.

Maybe I should have been more specific with my poor/corroded connections comment. I meant any joint that is not soldered: removal plug/sockets, spade lugs etc.

There is no comparison using a HEI dist. With HEI there is NO bal resistor & the 4 spade lugs; there is no Nichrome wire that can burn out as in the Mopar bal res. The HEI pick up plugs directly into the module, so one connection. On the Mop ECU pick up, there are two connections: dist plug/skt & ECU plug/skt. The HEI coil has 3 connections, harness from the module to the coil & wire from the ign sw. The Mop system has 5 connections, ign sw to bal res, bal res to ECU, ECU to coil.

If you are using the HEI module you can mount/install it such that it has less connection points than the std Mop ECU set up.

If you say so, my friend down under. I am mature enough to agree to disagree. ;)RRR,

Maybe I should have been more specific with my poor/corroded connections comment. I meant any joint that is not soldered: removal plug/sockets, spade lugs etc.

There is no comparison using a HEI dist. With HEI there is NO bal resistor & the 4 spade lugs; there is no Nichrome wire that can burn out as in the Mopar bal res. The HEI pick up plugs directly into the module, so one connection. On the Mop ECU pick up, there are two connections: dist plug/skt & ECU plug/skt. The HEI coil has 3 connections, harness from the module to the coil & wire from the ign sw. The Mop system has 5 connections, ign sw to bal res, bal res to ECU, ECU to coil.

If you are using the HEI module you can mount/install it such that it has less connection points than the std Mop ECU set up.

Dave999

Well-Known Member

any mag pickup distributor will cause the advance to retard with RPM its the one slight negtive

the spinning reluctor, as it passes the pickup pole, gains its own magnetic field due to its movmnet past the magnetic pickup.

its own field distorts that of the pickup and as magnetic fields and the currents they induce in near by coils of wire is totally dependedent on the speed you cut through the lines of magnetic flux the induced magentisim in the reluctor star gets bigger the fast you go

this messes with the pickup field in a manner that results in the igntion timing reatarding slightly as RPM increses.

but this issue is totally outweighed by the benefit of a magntic pickup output haveing both timing and RPM information in it

timing is the trigger pulses,

rpm is the voltage size of the pulses

you don't get that with points OR hall effect pickups which are really just encoders of a position. thay in essence can only provide timing not rpm in a basic igntion.

the other retard that any electronic system adds to the equation is based on its function and is the same across the operable rpm range i.e its catered for when you set the poistion of the distributor in the block

i.e 5 btdc with a points distributor postion marked exactly will not be 5btdc with the electronic dizzy if marked and set into the block in excatly the sme position.

but you don't set timing based on position of distributor you use position of distributor to set the timing based on spark and damper TDC mark position. so its a moot point.

MSD type igntions do retard

you switch from 3 sparks to 1 spark at a specific rpm you sometimes see a retard when they change mode of operation. but as this is a race igntion they don't expect you to be racing in that rpm range.

i rambled on on this link but provided some links to more info

Dual-point vs. Single-point distributors - pros and cons?

hei looks at the size of the pluse and decides if its time to switch OFF its current limiting

an action that helps maintain the same spark power from idle to 6000 rpm

the limiting is designed to keep the coil cool, and to stop you cooking the coil if you leave the car igntion switch in RUN with the engine stalled.

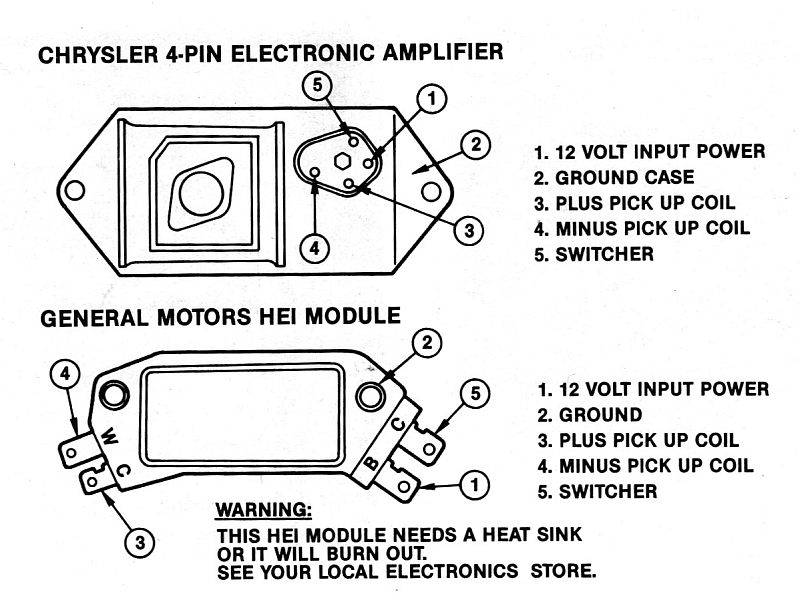

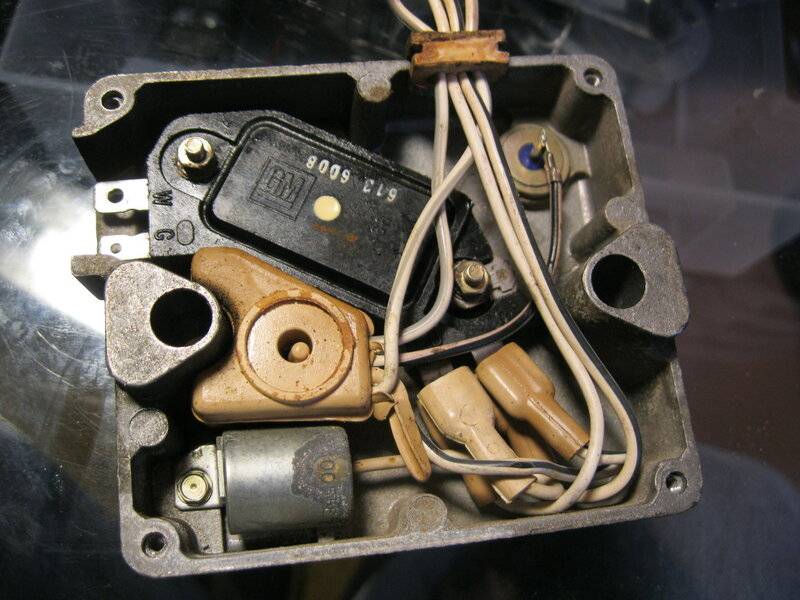

the FBO box looks like a copy of the Lucas AB14 CEI ingtion box used on jaguars in the 70s/80s see picture below. note use of radio supression capcitor and a press fit zener diode in coil/module negative to act as a clamp.... (in the jag ab14 box below)

FBO's benefits from a nice modern and potentally the best 4 pin module and a mopar connector, but you can make one yourself usuing the guts of your old mopar igntion amp and any mid priced known brand 4 pin HEI.

big gap small gap

too big too small both bad

the aim is to have one that works at all rpms

hei specified 45 thou that was for the big chevy distributor with a diameter twice the size of a mopar.

35 thou seems ok on my six cylinder with a mopar dizzy. This size gap and a full HEI system with a reverse zener diode protection clamp has my car running leagues better because it now ignites mixtures that previously were un ignitable by the old igntion set up.... HEI was designed to make a chevy with a horrible restrictive first year of catalytic converters ... actullay run... and this on a motor where they didn't even have the mopar benefit of the valves being positioned to open into the widest diameter line, of the cylinder bore... think standard cam poor flowing inlet and a massively restictive exhaust.... none of us have those problems which means the ignition is going to be complete overkill... or as i like to think of it.....an upgrade.

if they used 4 pin HEIs on v12 jaguars, a mopar with reasonably sensible static CR should be no problem.

the spinning reluctor, as it passes the pickup pole, gains its own magnetic field due to its movmnet past the magnetic pickup.

its own field distorts that of the pickup and as magnetic fields and the currents they induce in near by coils of wire is totally dependedent on the speed you cut through the lines of magnetic flux the induced magentisim in the reluctor star gets bigger the fast you go

this messes with the pickup field in a manner that results in the igntion timing reatarding slightly as RPM increses.

but this issue is totally outweighed by the benefit of a magntic pickup output haveing both timing and RPM information in it

timing is the trigger pulses,

rpm is the voltage size of the pulses

you don't get that with points OR hall effect pickups which are really just encoders of a position. thay in essence can only provide timing not rpm in a basic igntion.

the other retard that any electronic system adds to the equation is based on its function and is the same across the operable rpm range i.e its catered for when you set the poistion of the distributor in the block

i.e 5 btdc with a points distributor postion marked exactly will not be 5btdc with the electronic dizzy if marked and set into the block in excatly the sme position.

but you don't set timing based on position of distributor you use position of distributor to set the timing based on spark and damper TDC mark position. so its a moot point.

MSD type igntions do retard

you switch from 3 sparks to 1 spark at a specific rpm you sometimes see a retard when they change mode of operation. but as this is a race igntion they don't expect you to be racing in that rpm range.

i rambled on on this link but provided some links to more info

Dual-point vs. Single-point distributors - pros and cons?

hei looks at the size of the pluse and decides if its time to switch OFF its current limiting

an action that helps maintain the same spark power from idle to 6000 rpm

the limiting is designed to keep the coil cool, and to stop you cooking the coil if you leave the car igntion switch in RUN with the engine stalled.

the FBO box looks like a copy of the Lucas AB14 CEI ingtion box used on jaguars in the 70s/80s see picture below. note use of radio supression capcitor and a press fit zener diode in coil/module negative to act as a clamp.... (in the jag ab14 box below)

FBO's benefits from a nice modern and potentally the best 4 pin module and a mopar connector, but you can make one yourself usuing the guts of your old mopar igntion amp and any mid priced known brand 4 pin HEI.

big gap small gap

too big too small both bad

the aim is to have one that works at all rpms

hei specified 45 thou that was for the big chevy distributor with a diameter twice the size of a mopar.

35 thou seems ok on my six cylinder with a mopar dizzy. This size gap and a full HEI system with a reverse zener diode protection clamp has my car running leagues better because it now ignites mixtures that previously were un ignitable by the old igntion set up.... HEI was designed to make a chevy with a horrible restrictive first year of catalytic converters ... actullay run... and this on a motor where they didn't even have the mopar benefit of the valves being positioned to open into the widest diameter line, of the cylinder bore... think standard cam poor flowing inlet and a massively restictive exhaust.... none of us have those problems which means the ignition is going to be complete overkill... or as i like to think of it.....an upgrade.

if they used 4 pin HEIs on v12 jaguars, a mopar with reasonably sensible static CR should be no problem.

Last edited:

Great description should become a article!

512Stroker

We are all here because we are not all there.

Rat, I have been running one of Don's white boxes for three years.I‘m not sure which box he was talking about when he said it doesn’t retard with RPM.

Like I said, they ALL retard with RPM. How much and when it starts are variables.

Thats why you need to test for it.

I was there when Don started talking about building his own ignition boxes. I said it was a waste of time. I still say that.

It has performed very well, no issues, and I really like the rev limiter.

512Stroker

We are all here because we are not all there.

Switcher? Never heard that termany mag pickup distributor will cause the advance to retard with RPM its the one slight negtive

the spinning reluctor, as it passes the pickup pole, gains its own magnetic field due to its movmnet past the magnetic pickup.

its own field distorts that of the pickup and as magnetic fields and the currents they induce in near by coils of wire is totally dependedent on the speed you cut through the lines of magnetic flux the induced magentisim in the reluctor star gets bigger the fast you go

this messes with the pickup field in a manner that results in the igntion timing reatarding slightly as RPM increses.

but this issue is totally outweighed by the benefit of a magntic pickup output haveing both timing and RPM information in it

timing is the trigger pulses,

rpm is the voltage size of the pulses

you don't get that with points OR hall effect pickups which are really just encoders of a position. thay in essence can only provide timing not rpm in a basic igntion.

the other retard that any electronic system adds to the equation is based on its function and is the same across the operable rpm range i.e its catered for when you set the poistion of the distributor in the block

i.e 5 btdc with a points distributor postion marked exactly will not be 5btdc with the electronic dizzy if marked and set into the block in excatly the sme position.

but you don't set timing based on position of distributor you use position of distributor to set the timing based on spark and damper TDC mark position. so its a moot point.

MSD type igntions do retard

you switch from 3 sparks to 1 spark at a specific rpm you sometimes see a retard when they change mode of operation. but as this is a race igntion they don't expect you to be racing in that rpm range.

i rambled on on this link but provided some links to more info

Dual-point vs. Single-point distributors - pros and cons?

hei looks at the size of the pluse and decides if its time to switch OFF its current limiting

an action that helps maintain the same spark power from idle to 6000 rpm

the limiting is designed to keep the coil cool, and to stop you cooking the coil if you leave the car igntion switch in RUN with the engine stalled.

the FBO box looks like a copy of the Lucas AB14 CEI ingtion box used on jaguars in the 70s/80s see picture below. note use of radio supression capcitor and a press fit zener diode in coil/module negative to act as a clamp.... (in the jag ab14 box below)

FBO's benefits from a nice modern and potentally the best 4 pin module and a mopar connector, but you can make one yourself usuing the guts of your old mopar igntion amp and any mid priced known brand 4 pin HEI.

big gap small gap

too big too small both bad

the aim is to have one that works at all rpms

hei specified 45 thou that was for the big chevy distributor with a diameter twice the size of a mopar.

35 thou seems ok on my six cylinder with a mopar dizzy. This size gap and a full HEI system with a reverse zener diode protection clamp has my car running leagues better because it now ignites mixtures that previously were un ignitable by the old igntion set up.... HEI was designed to make a chevy with a horrible restrictive first year of catalytic converters ... actullay run... and this on a motor where they didn't even have the mopar benefit of the valves being positioned to open into the widest diameter line, of the cylinder bore... think standard cam poor flowing inlet and a massively restictive exhaust.... none of us have those problems which means the ignition is going to be complete overkill... or as i like to think of it.....an upgrade.

if they used 4 pin HEIs on v12 jaguars, a mopar with reasonably sensible static CR should be no problem.

View attachment 1716023901

View attachment 1716023902

Dave999

Well-Known Member

and you can get a 4 pin hei module everywhere

used on all GM

used on renault

alfa romeo

you can get wells

nordoff

borgwarner

delco

hella

bosch austrlian bosch is different shape

Lucas

napa

echlin

same old motorola chip

modern ones can put up with 500V back emf off the primary hence don't strictly need the 350V zener diode that jaguar used on the orginal delco module in its lucas AB14 that could only put up with 350V

jaguar guys can buy a new AB14 for £200

or replace the module in their broken one for $25

many of them miss this fact....

or you can buy the motorola chip and make an HEI using support components from digi key on strip board, and tune it to any coil you want, with a differtent dwell and different current limit.

its not worth the effort but for testing, before you ....ask a chinese factiry to make you some modules, it may make sense

all of the modules will have the implementation suggested by motorola back in 1974 and the only differnce is the care thay take over quality control and the settings they choose by the their choice of the supporting componentry

i.e matching it to a specific coil.

this is how some modules can be sold with the tag line high performance they tweaked some resistor values to increase the current or adjust the dwell managment

that involves a laser etching or not etching a few lines in the surface of some silicone on an automated line.

expect the vast majority of modules regardless of the box or lable, to come out of the same factory.

The middle of the sandwich is still the same motorola chip.

Dave

used on all GM

used on renault

alfa romeo

you can get wells

nordoff

borgwarner

delco

hella

bosch austrlian bosch is different shape

Lucas

napa

echlin

same old motorola chip

modern ones can put up with 500V back emf off the primary hence don't strictly need the 350V zener diode that jaguar used on the orginal delco module in its lucas AB14 that could only put up with 350V

jaguar guys can buy a new AB14 for £200

or replace the module in their broken one for $25

many of them miss this fact....

or you can buy the motorola chip and make an HEI using support components from digi key on strip board, and tune it to any coil you want, with a differtent dwell and different current limit.

its not worth the effort but for testing, before you ....ask a chinese factiry to make you some modules, it may make sense

all of the modules will have the implementation suggested by motorola back in 1974 and the only differnce is the care thay take over quality control and the settings they choose by the their choice of the supporting componentry

i.e matching it to a specific coil.

this is how some modules can be sold with the tag line high performance they tweaked some resistor values to increase the current or adjust the dwell managment

that involves a laser etching or not etching a few lines in the surface of some silicone on an automated line.

expect the vast majority of modules regardless of the box or lable, to come out of the same factory.

The middle of the sandwich is still the same motorola chip.

Dave

Last edited:

If Needed I have some NOS Delco ones listed, prob from the 80's

[FOR SALE] - NOS Delco 4 pin HEI module tested

[FOR SALE] - NOS Delco 4 pin HEI module tested

Dave999

Well-Known Member

as in switch that switches the coil off and onSwitcher? Never heard that term

your points are just a switch, two contacts that touch to switch the coil on and part to switch it off

switch off the coil to trigger a spark

with a module or igntion box, mopar or hei you have a silicon based emulation of a switch

they use a big industrial transistor to switch the coil off and on

pin 5 switches the coil off and on

hence in that diagram gets called the switcher...

not right but not wrong. cos it does switch

i'm sure better terms exist

depending on the type of box

you have 12 volts into pin 1

and 12 volts to your coil +

if the switcher, pin 5 is at 0v,then the coil is on. 12 volts at coil + and 0 volts at coil - means flow of current in coil...

if the swicher pin 5, is switched to 12 volts, the coil + and coil - are both at 12 volts, both the same, coil sees no voltage or difference between + and - so the coil is off.

switching it off causes the spark.

basically all you need is pin 5 to coil - and pin 1 to coil + with 12 volts connected to coil +

and the module bolted to the car and earthed through the screw next to pins 1 and 5. and that is the "high power" end of the install done

other end of module is all about tiny trigger signal from the dizzy.

proper HEI coil works better than the blaster 2 in this kind of retrofit set up and costs $25 rather than $80

dave

Last edited:

Dam Dave you are spot on!

Dave999

Well-Known Member

Rat Bastid

Dunamis Metron

RB,

What you fail to understand is that when you put that big cam in an engine & it runs rough at idle, the engine is misfiring. Even stock engines misfire but you do not notice/hear it. If you can reduce or eliminate misfiring, you make more power.

At idle & low speeds, a long duration spark is needed with a lot of heat in it. Inductive ign provides a long duration spark, ideal for the purpose. This is why modern engines use high energy systems with big plug gaps to run leaner mixtures & reduce emissions.

Try running points ign & 0.025" plug gaps on one of these engines....

From the Bosch Automotive Handbook: ' An ign spark energy of approx 0.2mj is adequate to ignite a stoichometric A/F mixture, while richer or leaner mixtures require substantially higher levels of spark energy'........'On the one hand, the electrode gap should be as wide as possible so that the spark reaches as large an air-fuel volume as possible & the mixture is rapidly & reliably ignited so that the engine runs smoothly'. ..........'It is frequently impossible to achieve smooth idle when the electrode gap is too narrow'.

Phil Jacobs, founder of Jacobs Ign Systems, claims 0.100" is the ideal spark plug gap.....

I‘ve read what Jacobs said. He was focused on street junk mostly.

I can tell you I have tested and wasted more time testing plug gaps because guys read **** like this in books, magazines and now on the interwebs and NEVER did I find power in big plug gaps.

Not once.

Rat Bastid

Dunamis Metron

Rat, I have been running one of Don's white boxes for three years.

It has performed very well, no issues, and I really like the rev limiter.

I‘m sure they do work fine.

My problem is his claim they don’t retard with RPM.

My cheap *** isn’t going to buy one of his systems to test his claim, but if someone sends me one to test I will test it and video the entire test.

I say it does retard with RPM because they ALL do it.

As long as that is known and it’s accounted for it doesn’t really matter. But you have to know and account for it.

Last edited:

Rat Bastid

Dunamis Metron

RB,

Because you didn't find any power in plug gaps does not mean there isn't any. Power is not just at peak power, it is from idle on upwards.

No kidding? What makes you think I was looking at peak power ONLY? You assumed.

And I’m not the only one who has extensively tested plug gap and found ZERO.

But I have replaced a battery fired ignition with .035 plug gaps with a 4 amp mag that used an .022 gap and the mag was 45 HP up on that engine.

Most of the time it was a 20 HP gain over a battery fired ignition. All with .022 plug gaps.

Hmmmmmmmm…

I know people talk about the high RPM retard on some of these ignitions as if it's a bad thing. It's not always. If you have a combination that's on the ragged edge (as is all the rage these days) you may find high RPM retard desirable. You don't WANT the timing as far advanced as possible at high RPM in some of those combinations. It might be a recipe for disaster.

Rat Bastid

Dunamis Metron

I know people talk about the high RPM retard on some of these ignitions as if it's a bad thing. It's not always. If you have a combination that's on the ragged edge (as is all the rage these days) you may find high RPM retard desirable. You don't WANT the timing as far advanced as possible at high RPM in some of those combinations. It might be a recipe for disaster.

That’s exactly why you have to test for it. You might be surprised that most NA cars want MORE timing in low gear, “standard” timing through the middle and MORE timing again in high gear.

It depends largely on load and VE in high gear

If you don’t know when an ignition starts to retard and when it retards then you have no idea what you actually have for timing.

I used to advocate for (and did it all the time) locked out advance on most any performance build.

Once I learned about ignition retard is STOPPED doing that and build some kind of curve for everything.

Yup and another thing, engine A built a certain way will want different timing than engine B built the same way. Every dang time. It's just not something that's set in stone. You have to tune for it.That’s exactly why you have to test for it. You might be surprised that most NA cars want MORE timing in low gear, “standard” timing through the middle and MORE timing again in high gear.

It depends largely on load and VE in high gear

If you don’t know when an ignition starts to retard and when it retards then you have no idea what you actually have for timing.

I used to advocate for (and did it all the time) locked out advance on most any performance build.

Once I learned about ignition retard is STOPPED doing that and build some kind of curve for everything.

RB,

Post #25, your bulls**t claim : 'Big plug gap doesn't make power'. Another bull s**t claim: the HEI adv mech is overrated.

Even you should be able to understand that a 045 gap is bigger than 030. Testing & reported in Graham Bell's book, 4 stroke Performance Tuning, on a stock HEI equipped 350 Chev 6-7 more hp at 3500-4000 rpm range with the larger plug gap.

A test on a 351W with HEI ign & 040 plug gaps made 601 hp @ 7000 & with CD ign & 060 plug gaps made 613 HP @ 7000.

GM dists, both points & HEI have about the most adjustable centri adv mechanism on the planet. There are a large number of different centre plates as well as weights that allow for a huge range of timing curves.

Post #25, your bulls**t claim : 'Big plug gap doesn't make power'. Another bull s**t claim: the HEI adv mech is overrated.

Even you should be able to understand that a 045 gap is bigger than 030. Testing & reported in Graham Bell's book, 4 stroke Performance Tuning, on a stock HEI equipped 350 Chev 6-7 more hp at 3500-4000 rpm range with the larger plug gap.

A test on a 351W with HEI ign & 040 plug gaps made 601 hp @ 7000 & with CD ign & 060 plug gaps made 613 HP @ 7000.

GM dists, both points & HEI have about the most adjustable centri adv mechanism on the planet. There are a large number of different centre plates as well as weights that allow for a huge range of timing curves.

Rat Bastid

Dunamis Metron

RB,

Post #25, your bulls**t claim : 'Big plug gap doesn't make power'. Another bull s**t claim: the HEI adv mech is overrated.

Even you should be able to understand that a 045 gap is bigger than 030. Testing & reported in Graham Bell's book, 4 stroke Performance Tuning, on a stock HEI equipped 350 Chev 6-7 more hp at 3500-4000 rpm range with the larger plug gap.

A test on a 351W with HEI ign & 040 plug gaps made 601 hp @ 7000 & with CD ign & 060 plug gaps made 613 HP @ 7000.

GM dists, both points & HEI have about the most adjustable centri adv mechanism on the planet. There are a large number of different centre plates as well as weights that allow for a huge range of timing curves.

Yep, read that. And you know what? In the real world on the dyno and on the track big gaps don’t do ****.

Simple as that.

As far as the garbage GM/HEI advance mechanism o stand by what I said. Billions of them were made, but that doesn’t make them the best.

The guys who claim they can tune one without pulling the distributor don’t have a clue what they are changing. To do it right, it needs to come out.

What can you do with that cheesy GM mechanism that you can’t do with something else?

Just silly.

EDIT: My claims are no more bullshit that the garbage you posted claiming big gaps makes power.

No one, and I mean NO ONE I know that I can verify they have tested plug gaps says a bigger gap is better.

Once again, explain how a magneto makes more power on a smaller gap.

Oh wait, it’s because even the most basic magneto puts out 3 amps. That’s THREE HUNDRED PERCENT more energy at the plug than ANY battery fired ignition.

Get into the real world.

RB,

[1] The bulls**t king. I never said the HEI dist adv should not be removed to change the curve. As for the BS about being able to do the same with 'something else' as the HEI centri mechanism: there were at least 3 different shaped weights available & at least 32 [ yes 32! ] centre plates available; & I am not sure if this is the complete list. The weights/centre plate can also be ground or welded up to give an almost infinite amount of combinations. Name another brand of dist that has this number of combinations available.

The total timing limit is easily done, I use a nut & bolt on the rotor mounting plate, very simple, & there are other ways.

[2] Bulls**t #2: mag with 3 amps output, puts out 300% more than ANY battery fired ign, so that would be 1 amp.

The MSD coil #8261 teamed with MSD7 puts out 2 amps...

MSD coil #8251 puts out 1.1 amps......

[3] MSD recommend 0.050- 0.060" plug gaps as a starting point for up to 10.5:1 CR engines with the MSD 6 ign. Why would they do that if there was nothing to gain with increased plug gaps??????

[4] The Pro mag 44 requires a 16 volt battery. Doubt many here have 16 v batteries....

[5] I have provided test results showing power gains from bigger plug gaps.

[6] Manufacturers do not spend $$$$ on better ign systems to run smaller plug gaps, they could use what they already have....or go back to points ign...

[1] The bulls**t king. I never said the HEI dist adv should not be removed to change the curve. As for the BS about being able to do the same with 'something else' as the HEI centri mechanism: there were at least 3 different shaped weights available & at least 32 [ yes 32! ] centre plates available; & I am not sure if this is the complete list. The weights/centre plate can also be ground or welded up to give an almost infinite amount of combinations. Name another brand of dist that has this number of combinations available.

The total timing limit is easily done, I use a nut & bolt on the rotor mounting plate, very simple, & there are other ways.

[2] Bulls**t #2: mag with 3 amps output, puts out 300% more than ANY battery fired ign, so that would be 1 amp.

The MSD coil #8261 teamed with MSD7 puts out 2 amps...

MSD coil #8251 puts out 1.1 amps......

[3] MSD recommend 0.050- 0.060" plug gaps as a starting point for up to 10.5:1 CR engines with the MSD 6 ign. Why would they do that if there was nothing to gain with increased plug gaps??????

[4] The Pro mag 44 requires a 16 volt battery. Doubt many here have 16 v batteries....

[5] I have provided test results showing power gains from bigger plug gaps.

[6] Manufacturers do not spend $$$$ on better ign systems to run smaller plug gaps, they could use what they already have....or go back to points ign...

GM played around with big plug gaps in the mid to late 70s. Buick had a plug gap at one time or another that was .120". All I can add is, if big plug gaps did anything "extra" the factories would be using them. They aren't.

-

Similar threads

- Replies

- 13

- Views

- 545