POS Dakota

Anti-Socialist

What is called hard anodizing requires some expensive processes and actually serves no purpose mechanically in this application. The design of the rockers provide for no aluminum wear surfaces. Anodizing these rockers would just add cost and make them a pretty color and I'm pretty sure that the Hughes site actually mentions that somewhere.

The purpose of anodizing is to harden the surface of the aluminum. This makes it more abrasion resistant and more corrosion resistant. Neither of these attributes are required for these rocker arms.

My Crane Gold Race rockers are hard anodized gold. Anyone who has a set can tell you that they generally have a final step before they are ready after anodizing, they hone the inside of the rocker, do any required thread chasing and ream the holes for the rollers and install the rollers. Why? Because the aluminum actually grows in the hard anodizing process. Some of the color will be removed from the bore when they hone them to fit the shafts but it will still be hard anodized. That surface is a bearing surface and the hard anodizing is just a little extra insurance against premature wear.

The color that you see on many anodized aluminum parts is optional and is nothing more than aesthetics or color coding. I use nuts for aircraft fasteners at work that are anodized aluminum. This app requires the anodizing. Different colors are used to designate different types of nuts (that are actually called collars). The "nut" part of the collar breaks off when the correct torque is reached and the "collar" is left behind instead of a nut. They are very light and strong and very corrosion and tamper resistant.

http://www.electrohio.com/Finishing/AlAnodizing/AlAnodizing.htm

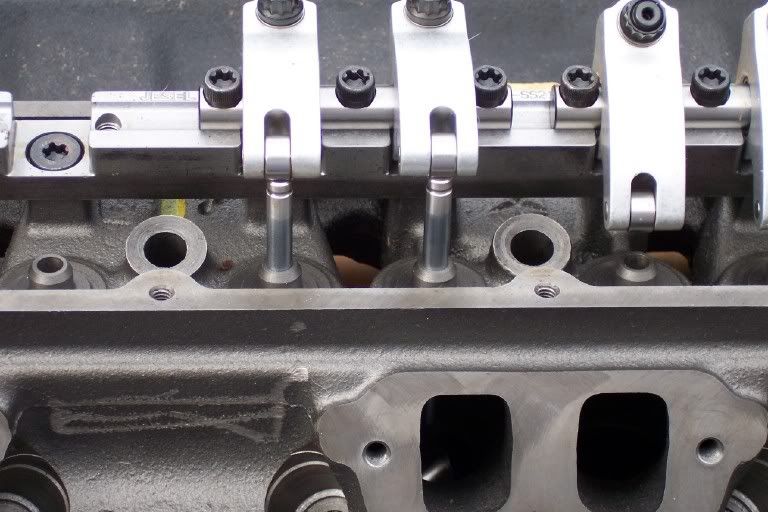

And yup, POS, Jesel hasn't been anodizing in about twenty years, but no...there stuff is a proprietary blend in the 7000 series.....and it costs 4 times as much money....and they don't make a set for a magnum motor! I'm not even sure they make a set for a typical LA.

T&D does not anodize their stuff either and their site does not say what aluminum alloy the rockers are manufactured form. It may also be a 7000 series but keep in mind that these are being used in engines with crazy spring pressures and very high RPM. The rockers have less mass and require the extra strength and, once again, the price is real steep! LOL

I'm totally happy with the hughes. The price is right.

I will not be even close to 7000 rpm. I'll probably limit the engine to 6500 to fall back on about 6000-6200 on the 1-2.

For the price, there is nothing IMO that is really comparable with maybe the exception of the harlands, but I really dont know about them. There are some from racer brown, but the pics I saw of them were ****.

I am not up for paying over a grand for rockers though when I really dont need them on a motor, but when I do need them....

check these out! hehe

:yawinkle: