This is an 8.8 Ford (in my F150), but the gears don't know that. (ssshhh!)

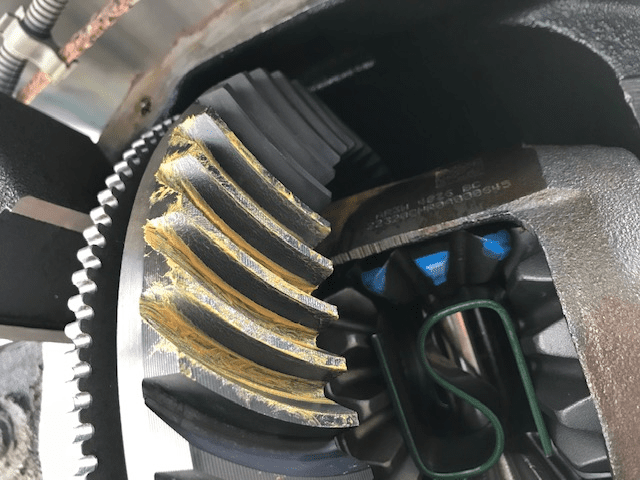

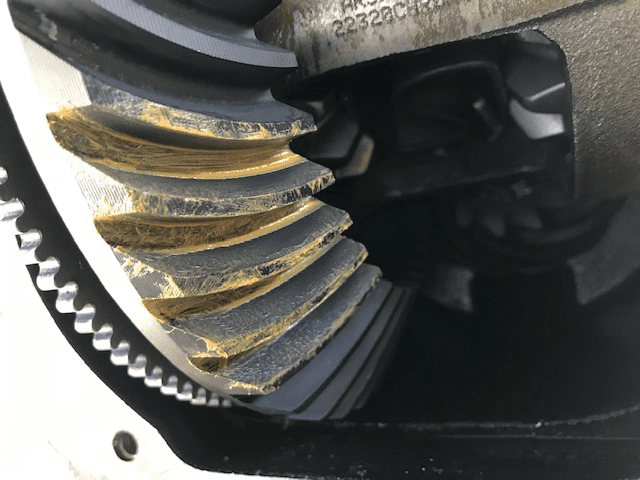

I have limited experience setting up gears, but I've never seen a pattern that encompasses the entire tooth, drive and coast. And I don't see any pictures like these online.

I used Ford Motorsport gears (going from 2.73 open, to 3.31's w/ a Traction Lok. I used the original pinion shim, and the original left side carrier shim. There's about .008 back lash, the spec is .008 to .012.

I have limited experience setting up gears, but I've never seen a pattern that encompasses the entire tooth, drive and coast. And I don't see any pictures like these online.

I used Ford Motorsport gears (going from 2.73 open, to 3.31's w/ a Traction Lok. I used the original pinion shim, and the original left side carrier shim. There's about .008 back lash, the spec is .008 to .012.

Good info for me. I'll give it another go! Thanks

Good info for me. I'll give it another go! Thanks