You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glamour Shots.. '62 Valiant Wagon

- Thread starter slant six

- Start date

-

10-29-23:

I was able to get the k frame separated from the engine and also the steering box off the K frame.

Got some degreasing and cleaning of the k frame done..

And the steering box got cleaned too.

I was able to get the k frame separated from the engine and also the steering box off the K frame.

Got some degreasing and cleaning of the k frame done..

And the steering box got cleaned too.

Last edited:

11-3-23:

Got the Trans, Bell, flywheel, and PS Pump pulled off the Engine block.

Started detailing some small parts too:

Hope to have a block broken down and degreased / off to the machine shop by Monday.

I got new pistons and rings for it. Will be bored 0.060" over.

Got the Trans, Bell, flywheel, and PS Pump pulled off the Engine block.

Started detailing some small parts too:

Hope to have a block broken down and degreased / off to the machine shop by Monday.

I got new pistons and rings for it. Will be bored 0.060" over.

11/6/23:

I got the engine all broken down and torn apart. It was super sludgy inside and out.

I will be cleaning, blasting, and respraying the tins, and rebuilding things like the power steering pump.

We got the Block degreased and ready for the machine shop.

I was able to get the crank and block to the machine shop before work this morning and I should have it back for reassembly before Christmas!

There were no broken rings or piston lands or anything weird, just lots of glazing on the cylinder walls and spots where the engine had sat in one place without running for probably a few decades. I am going to have it bored 0.060" over and I will put new rings and pistons in it along with a different camshaft, a new timing set, a different head, and cam, main, and rod bearings.

The oil pump should be fine but I will check it all over to be sure. I will redo the poorly executed exhaust from the prior owner.

Some pictures:

Block parts disassembled:

Very Sludgy, dino turds from past decades, no amount of oil changes or cleaning strategies seemed to make the oil any better or not black instantly after changing it.

The helper was at the shop. She helped degrease the block before it went to the machine shop.

The kickback on the pressure washer was something for her to get used to.

The cylinders were super smooth - no evidence of a cross-hatch pattern anywhere except below the ring packs. Makes me think It sat a long time, the cylinders were rusted up and then the engine was started and the rings worked the cylinder crap into the walls knocking the hatching back to glass smooth.

The Head Rail Pad near the alternator may be missing a "5" after the 22? It is a 225 engine for sure., not a 170. Seems like someone took a smoke break a bit early on the line one day.

More cleaning 60-year-old gunk in the small parts washer tonight and all week at home.

I got the engine all broken down and torn apart. It was super sludgy inside and out.

I will be cleaning, blasting, and respraying the tins, and rebuilding things like the power steering pump.

We got the Block degreased and ready for the machine shop.

I was able to get the crank and block to the machine shop before work this morning and I should have it back for reassembly before Christmas!

There were no broken rings or piston lands or anything weird, just lots of glazing on the cylinder walls and spots where the engine had sat in one place without running for probably a few decades. I am going to have it bored 0.060" over and I will put new rings and pistons in it along with a different camshaft, a new timing set, a different head, and cam, main, and rod bearings.

The oil pump should be fine but I will check it all over to be sure. I will redo the poorly executed exhaust from the prior owner.

Some pictures:

Block parts disassembled:

Very Sludgy, dino turds from past decades, no amount of oil changes or cleaning strategies seemed to make the oil any better or not black instantly after changing it.

The helper was at the shop. She helped degrease the block before it went to the machine shop.

The kickback on the pressure washer was something for her to get used to.

The cylinders were super smooth - no evidence of a cross-hatch pattern anywhere except below the ring packs. Makes me think It sat a long time, the cylinders were rusted up and then the engine was started and the rings worked the cylinder crap into the walls knocking the hatching back to glass smooth.

The Head Rail Pad near the alternator may be missing a "5" after the 22? It is a 225 engine for sure., not a 170. Seems like someone took a smoke break a bit early on the line one day.

More cleaning 60-year-old gunk in the small parts washer tonight and all week at home.

11/7/23:

Starting to get some of the tins cleaned, there was about 3/8" of sludge and lead buildup in the bottom of the oil pan, It was very nasty.

Here are some of the degreased parts ready for blasting and painting:

Starting to get some of the tins cleaned, there was about 3/8" of sludge and lead buildup in the bottom of the oil pan, It was very nasty.

Here are some of the degreased parts ready for blasting and painting:

11/19/23:

Making some progress - Most of the engine parts are now desludged, there are still a few more bits to go, but mostly all clean.

The oil pan had a big whack pushed into it. my guess it the jack slipped off of the K frame at some point in the last 62 years.

A little hammer and dolly work has it back to flat again.

good as 62 years old and not smashed.

Some more parts sprayed after they were abrasive blasted:

Cleaning the rocker shaft and rockers, as well as rebuilding the PS Pump.

I was fortunate as the Rockers were not real sludgy, just on the outside surface which cleaned up nicely in the parts washer with the mineral spirits and a good metal wired welding brush.

All Clean!

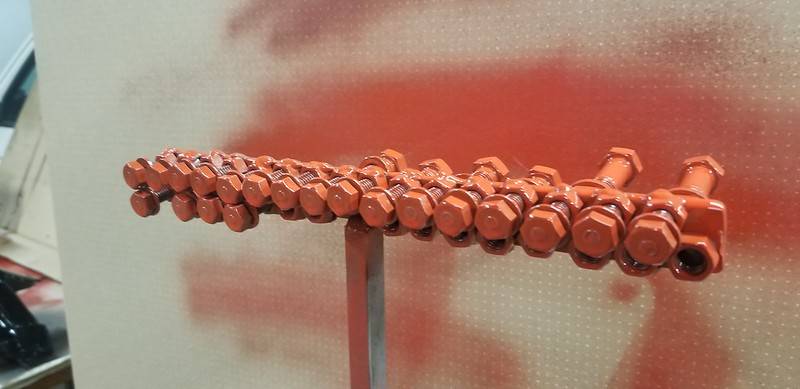

I made a little blasting/painting fixture for all of the little bolts that hold the tins on the engine. It seems to have worked well.

More parts fresh out of the blaster cabinet:

Making some progress - Most of the engine parts are now desludged, there are still a few more bits to go, but mostly all clean.

The oil pan had a big whack pushed into it. my guess it the jack slipped off of the K frame at some point in the last 62 years.

A little hammer and dolly work has it back to flat again.

good as 62 years old and not smashed.

Some more parts sprayed after they were abrasive blasted:

Cleaning the rocker shaft and rockers, as well as rebuilding the PS Pump.

I was fortunate as the Rockers were not real sludgy, just on the outside surface which cleaned up nicely in the parts washer with the mineral spirits and a good metal wired welding brush.

All Clean!

I made a little blasting/painting fixture for all of the little bolts that hold the tins on the engine. It seems to have worked well.

More parts fresh out of the blaster cabinet:

11/25/23:

Getting some more parts detailed:

I spent quite a bit of time today using the abrasive cabinet:

Getting some large parts ready for paint:

Oil pan bolts after cleaning, before abrasive blasting:

After glass beading in the abrasive cabinet:

Now getting some paint:

I am getting the K Frame sorted.

These were apparently Stick welded back in 1961-'62, and there are some questionable welds, lots of undercut, and at one point a welding rod stuck through the metal of the k frame itself.

I reinforced a few welds and reinforced some areas with massive amounts of undercut. I also did quite a bit of cleaning and paint prep.

Getting some paint put on:

Getting some more parts detailed:

I spent quite a bit of time today using the abrasive cabinet:

Getting some large parts ready for paint:

Oil pan bolts after cleaning, before abrasive blasting:

After glass beading in the abrasive cabinet:

Now getting some paint:

I am getting the K Frame sorted.

These were apparently Stick welded back in 1961-'62, and there are some questionable welds, lots of undercut, and at one point a welding rod stuck through the metal of the k frame itself.

I reinforced a few welds and reinforced some areas with massive amounts of undercut. I also did quite a bit of cleaning and paint prep.

Getting some paint put on:

Dfr360cuda

Diagnosis... Plum Crazy.

Great work

I clean up everything before I put it back together too.

I use this stuff before I sand blast. It makes the paint blister and comes off a lot easier.

Good luck with the cars.

I clean up everything before I put it back together too.

I use this stuff before I sand blast. It makes the paint blister and comes off a lot easier.

Good luck with the cars.

Dfr360cuda

Diagnosis... Plum Crazy.

My bad

Its the gasket remover that I use

Its the gasket remover that I use

Thanks for the tip.

The paint blows away pretty quick in the cabinet, but I might need it someday. Who knows maybe you'll be able to see the car completed in spring / summer at mineral beach!

11/27/23:

I got some time today to get all of the pistons, pins, and rods balanced and weight matched.

It's amazing to me that also the rod bearings from both King Bearings and Sealed Power are all weight matched to 0.1g according to my scale!

I got some time today to get all of the pistons, pins, and rods balanced and weight matched.

It's amazing to me that also the rod bearings from both King Bearings and Sealed Power are all weight matched to 0.1g according to my scale!

12/4/23:

Working on some small oil pan improvements:

I was able to test fit it on a spare block and check for crank clearance as well:

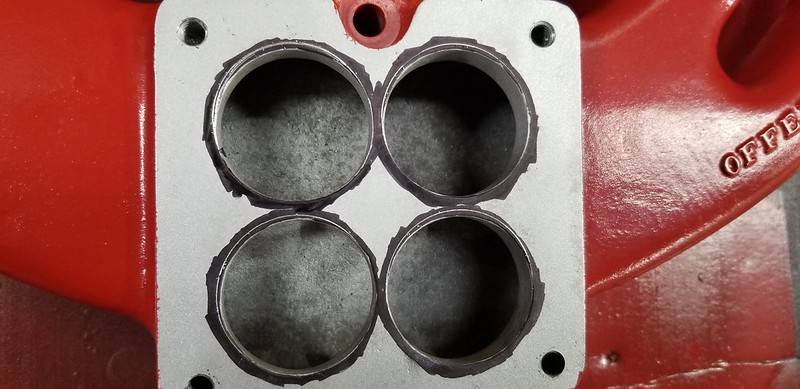

Next, some clean up on the intake. It needed some blasting and cleaning like the other parts.

Finally some more painting - Headers, Starter, (not shown), Oil Pan, and Intake.

Working on some small oil pan improvements:

I was able to test fit it on a spare block and check for crank clearance as well:

Next, some clean up on the intake. It needed some blasting and cleaning like the other parts.

Finally some more painting - Headers, Starter, (not shown), Oil Pan, and Intake.

12/11/23:

I finished detailing the intake, and found some offset by Offenhauser. This is to be expected with old hawt rod bolt ons.

No matter which way I swip-swapped the adapter pad there seemed to be some major.... let's call it core shift... providing a shelving unit right below all 4 carburetor blades.

To the poor mans steel blue layout fluid:

I actually have some steel blue, just not at this shop so to the sharpie pen I went, maybe Newell's Stock price will go up with all the sharpie I buy. :shock:

I got the major shelves ground away, and have some finish sanding to do with the Dremel and then it will be ready to install.

I finished detailing the intake, and found some offset by Offenhauser. This is to be expected with old hawt rod bolt ons.

No matter which way I swip-swapped the adapter pad there seemed to be some major.... let's call it core shift... providing a shelving unit right below all 4 carburetor blades.

To the poor mans steel blue layout fluid:

I actually have some steel blue, just not at this shop so to the sharpie pen I went, maybe Newell's Stock price will go up with all the sharpie I buy. :shock:

I got the major shelves ground away, and have some finish sanding to do with the Dremel and then it will be ready to install.

12/17/23:

I got the Intake all sorted out. I did not take any pictures of the after. Imagine 4 holes with no shelves or offsets.

Started working on the trailer frame hitch. It will also work for a bike rack which will be nice.

I started with the Curt 11000 listed for 2010-2014 VW Golf/GTI's which has 39" on center bolt holes - the A-bodies have a 36" OC frame in the rear of the unibody. So I cut 1 1/2" out of either side of the tube and then adjust the height of the mounting ears/hang down of the receiver so that it is not too low. (welding required)

I got the Intake all sorted out. I did not take any pictures of the after. Imagine 4 holes with no shelves or offsets.

Started working on the trailer frame hitch. It will also work for a bike rack which will be nice.

I started with the Curt 11000 listed for 2010-2014 VW Golf/GTI's which has 39" on center bolt holes - the A-bodies have a 36" OC frame in the rear of the unibody. So I cut 1 1/2" out of either side of the tube and then adjust the height of the mounting ears/hang down of the receiver so that it is not too low. (welding required)

12/24/23:

I finally got the Federal/TRW/Chrysler Power steering pump buttoned up.

I made a critical error on disassembly with not marking/punching the front bearing support and lock ring as described in the FSM. Fortunately I was able to rectify my ridiculous error by using the pump' inside witness marks behind the front bearing as a reference and was able to re assemble the slipper/pump rotor assembly with no binding.

It is ready to go back into service now!

I finally got the Federal/TRW/Chrysler Power steering pump buttoned up.

I made a critical error on disassembly with not marking/punching the front bearing support and lock ring as described in the FSM. Fortunately I was able to rectify my ridiculous error by using the pump' inside witness marks behind the front bearing as a reference and was able to re assemble the slipper/pump rotor assembly with no binding.

It is ready to go back into service now!

12/27/23:

I got the Frame hitch mocked up, drilled and mounted, then removed for a few coats of paint.

Holed marked and Drilled:

Hardware to be used; 1/2" carriage bolts, trailer hitch block plates (for inside the frame rails), and some 1/2-13 fishwire.

One more coat of paint today, then it will be ready for the final install.

I got the Frame hitch mocked up, drilled and mounted, then removed for a few coats of paint.

Holed marked and Drilled:

Hardware to be used; 1/2" carriage bolts, trailer hitch block plates (for inside the frame rails), and some 1/2-13 fishwire.

One more coat of paint today, then it will be ready for the final install.

12/28/23:

I went to accomplish some work on the valiant wagon yesterday, and I was able to get a lot of small jobs done.

I got the painted receiver hitch fully installed:

I wanted to begin building some of the exhaust as i removed the exhaust system from the Muffler shop and previous owners.

I am going to make my exhaust out of all 304 stainless with fully back purged welds. i started to lay out the parts and fired up the TIG machine, but realized that there was no 180° bends in 2 1/2" Ø tubing in my stash of exhaust building materials, so off to the parts catalog to order the required materials.

I revised the OE Tailpipe hanger - yes it was the original one from the factory in 1962, It was still covered with the original rustproofing / sound deadening material from the factory. - the rubber hanger / tire material was starting to give way so I figured I would save and restore it. - New Rubber and A bolt replace the factory rivet. I blasted and then painted what seemed like bare metal from the factory.

Factory rubber was needing replaced:

Rejuvenated factory tailpipe hanger:

Tailpipe hanger reinstalled:

I began working on the block..

I had a feeling that I would need the original Cam plug for the back of the block, so I saved it. I had this happen to me before when I was working on a '64 Truck block a while ago - some of the early blocks are machined for a larger rear cam plug - meaning the 2 9/64" Ø - Dorman 555-065 Plugs do not fit. - Too Small. My guess is the early cast iron blocks (this is a '62 Block) and the AL blocks use this larger plug?

I also gave the block a good bath and Began installing the camshaft bearings.

I went to accomplish some work on the valiant wagon yesterday, and I was able to get a lot of small jobs done.

I got the painted receiver hitch fully installed:

I wanted to begin building some of the exhaust as i removed the exhaust system from the Muffler shop and previous owners.

I am going to make my exhaust out of all 304 stainless with fully back purged welds. i started to lay out the parts and fired up the TIG machine, but realized that there was no 180° bends in 2 1/2" Ø tubing in my stash of exhaust building materials, so off to the parts catalog to order the required materials.

I revised the OE Tailpipe hanger - yes it was the original one from the factory in 1962, It was still covered with the original rustproofing / sound deadening material from the factory. - the rubber hanger / tire material was starting to give way so I figured I would save and restore it. - New Rubber and A bolt replace the factory rivet. I blasted and then painted what seemed like bare metal from the factory.

Factory rubber was needing replaced:

Rejuvenated factory tailpipe hanger:

Tailpipe hanger reinstalled:

I began working on the block..

I had a feeling that I would need the original Cam plug for the back of the block, so I saved it. I had this happen to me before when I was working on a '64 Truck block a while ago - some of the early blocks are machined for a larger rear cam plug - meaning the 2 9/64" Ø - Dorman 555-065 Plugs do not fit. - Too Small. My guess is the early cast iron blocks (this is a '62 Block) and the AL blocks use this larger plug?

I also gave the block a good bath and Began installing the camshaft bearings.

12/31/23:

I got some more things accomplished, I got the pistons/ pins and rods all mated up.

I made a fixture to locate the pin in the rod, it was a bit fussy at first and I need to redo a few of them, but I got some of them correct the first time, and i will tweak the others as needed before installation in the block.

I finished mocking up and welding the tail pipe. It's all in stainless so It will never need attention again in my lifetime. (I have had some cheap aluminized tubes rust from the inside out on one of my other cars that never was driven on the rain or snow/salt, so i build all of my exhausts in stainless now.)

Mockup / tackup - then test fit on the car.

Fully welded:

Frosty - not from Wendy's

Not all of them turn out like this, but when the gaps are right some nice beads can happen. Can always be better, but not bad for picking up the TIG Torch maybe once every 3 years.

I got some more things accomplished, I got the pistons/ pins and rods all mated up.

I made a fixture to locate the pin in the rod, it was a bit fussy at first and I need to redo a few of them, but I got some of them correct the first time, and i will tweak the others as needed before installation in the block.

I finished mocking up and welding the tail pipe. It's all in stainless so It will never need attention again in my lifetime. (I have had some cheap aluminized tubes rust from the inside out on one of my other cars that never was driven on the rain or snow/salt, so i build all of my exhausts in stainless now.)

Mockup / tackup - then test fit on the car.

Fully welded:

Frosty - not from Wendy's

Not all of them turn out like this, but when the gaps are right some nice beads can happen. Can always be better, but not bad for picking up the TIG Torch maybe once every 3 years.

abdywgn

dismantler

like the wagon!11/6/23:

I got the engine all broken down and torn apart. It was super sludgy inside and out.

I will be cleaning, blasting, and respraying the tins, and rebuilding things like the power steering pump.

We got the Block degreased and ready for the machine shop.

I was able to get the crank and block to the machine shop before work this morning and I should have it back for reassembly before Christmas!

There were no broken rings or piston lands or anything weird, just lots of glazing on the cylinder walls and spots where the engine had sat in one place without running for probably a few decades. I am going to have it bored 0.060" over and I will put new rings and pistons in it along with a different camshaft, a new timing set, a different head, and cam, main, and rod bearings.

The oil pump should be fine but I will check it all over to be sure. I will redo the poorly executed exhaust from the prior owner.

Some pictures:

Block parts disassembled:

Very Sludgy, dino turds from past decades, no amount of oil changes or cleaning strategies seemed to make the oil any better or not black instantly after changing it.

View attachment 1716163037

View attachment 1716163038

The helper was at the shop. She helped degrease the block before it went to the machine shop.

The kickback on the pressure washer was something for her to get used to.

View attachment 1716163039

The cylinders were super smooth - no evidence of a cross-hatch pattern anywhere except below the ring packs. Makes me think It sat a long time, the cylinders were rusted up and then the engine was started and the rings worked the cylinder crap into the walls knocking the hatching back to glass smooth.

View attachment 1716163040

The Head Rail Pad near the alternator may be missing a "5" after the 22? It is a 225 engine for sure., not a 170. Seems like someone took a smoke break a bit early on the line one day.

More cleaning 60-year-old gunk in the small parts washer tonight and all week at home.

Thanks!like the wagon!

Apparently, I do too.

I like this one as well:

1/2/24:

I finished up the tailpipe, it may still need some little adjustments, but it is all done, the muffler is sorted and placed, and I began working on the intermediate pipe today.

The intermediate pipe is finished up to the merge collector and, I would say there is not much more to do on the exhaust for now until the engine and transmission is back in the car.

Tailpipe and muffler deciding which route the intermediate pipe should take.

15° bends and 15° mitre cuts are your friends!

Some of those welds turn out nooice when the gaps are right.

That's all on the exhaust for now. Everything is fully welded in the pictures above. It will be time for me to build the head pipes from the headers to the merge collectors when the engine is back in the car.

I finished up the tailpipe, it may still need some little adjustments, but it is all done, the muffler is sorted and placed, and I began working on the intermediate pipe today.

The intermediate pipe is finished up to the merge collector and, I would say there is not much more to do on the exhaust for now until the engine and transmission is back in the car.

Tailpipe and muffler deciding which route the intermediate pipe should take.

15° bends and 15° mitre cuts are your friends!

Some of those welds turn out nooice when the gaps are right.

That's all on the exhaust for now. Everything is fully welded in the pictures above. It will be time for me to build the head pipes from the headers to the merge collectors when the engine is back in the car.

1/8/23:

I made a fixture to mount the Kent Moore universal piston pin / connecting rod holding tool. Buying the complete set new/ used can cost anywhere from $600-$2000, and I found a bunch of used partial sets of the tool. I can use my press and a socket to do most of the work that the Kent Moore tool sets provide. The Kent Moore Set is way nicer and less fussy, but what I made has worked so far for ~$200. It's not as fancy as the entire K-M tool, but it did work after I placed a few pins in the wrong spot with the rod heater method.

Now I am ready to begin assembly on the engine. I still need to pick a head and Cam, but everything else is sorted out.

Block Prep and wash complete - Cam bearings and plugs are completely installed as well as oil gallery plugs.

Block painting is mostly done too.

I made a fixture to mount the Kent Moore universal piston pin / connecting rod holding tool. Buying the complete set new/ used can cost anywhere from $600-$2000, and I found a bunch of used partial sets of the tool. I can use my press and a socket to do most of the work that the Kent Moore tool sets provide. The Kent Moore Set is way nicer and less fussy, but what I made has worked so far for ~$200. It's not as fancy as the entire K-M tool, but it did work after I placed a few pins in the wrong spot with the rod heater method.

Now I am ready to begin assembly on the engine. I still need to pick a head and Cam, but everything else is sorted out.

Block Prep and wash complete - Cam bearings and plugs are completely installed as well as oil gallery plugs.

Block painting is mostly done too.

-

Similar threads

- Replies

- 2

- Views

- 143

- Replies

- 4

- Views

- 662