myasylum

Well-Known Member

O.k. First... I'm not real good with this timing stuff I know.

Now that I got that out of the way... Let me explain what I find to me odd...

I have a 408 stroker motor wit a lunati voodoo 60403 cam, and a stock Distributor.

Just tiring to set the inital timing doesn't seem to make sense. (we'll start off there).

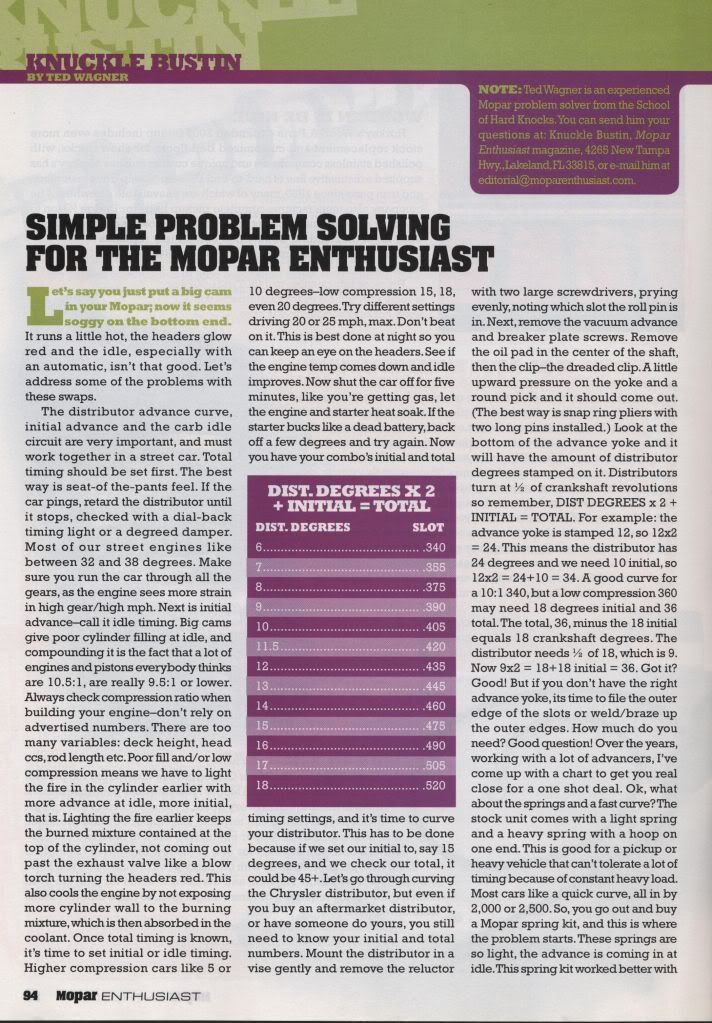

It won't even run at 0 degrees, and it wont run at 12 degrees. It will first run at about 20. It seems to run best at about 30 degrees initial timing. When I went to check total timing by increasing the rpm's the timing doesn't move. It stays at 30 degrees.

I did have a "mechanic" look at it, and he said it didn't make any sense to him. He just looked at me and said... "Well??? It runs!" That's as much as he could tell me.

Could someone go a little further into this please?

Thanks!

Now that I got that out of the way... Let me explain what I find to me odd...

I have a 408 stroker motor wit a lunati voodoo 60403 cam, and a stock Distributor.

Just tiring to set the inital timing doesn't seem to make sense. (we'll start off there).

It won't even run at 0 degrees, and it wont run at 12 degrees. It will first run at about 20. It seems to run best at about 30 degrees initial timing. When I went to check total timing by increasing the rpm's the timing doesn't move. It stays at 30 degrees.

I did have a "mechanic" look at it, and he said it didn't make any sense to him. He just looked at me and said... "Well??? It runs!" That's as much as he could tell me.

Could someone go a little further into this please?

Thanks!