jrcr_15

Well-Known Member

- Joined

- Jan 3, 2006

- Messages

- 125

- Reaction score

- 36

Hi everyone, I am installing a high amp alternator on my Duster and have a question about the wires to the starter relay / starter. (the "red" ones)

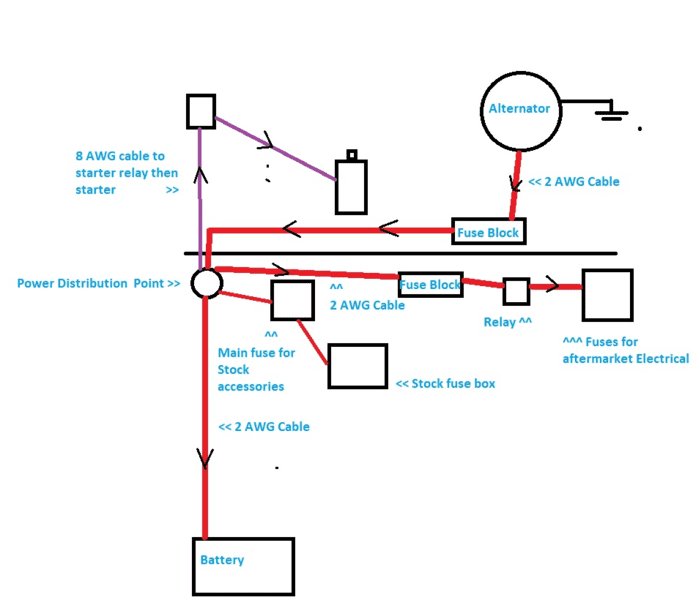

I am installing a high amp alternator and as such, I am running a heavy #2 gauged cable from the alternator to an appropriately sized fuse then through the firewall (no bulkhead) to a power distribution point. This distribution point will feed:

1) The batteries which were relocated to the trunk

2) Power to the starter relay

3) Power to the starter

4) New painless wiring harness / main fuse (no ammeter)

5) I am also installing a second separate fuse panel under the dash for the aftermarket electrical items I have installed on the car too. Water pump, fans, fuel pumps, Fitech, water-meth system, stereo etc. This too will be fed from this main distribution point.

I know that my "order" of connections may seem a bit off, but I do believe I have it right overall given the flow of power from the alternator to the batteries. However.. before cutting and going forward, I wanted to clarify I am on the right track regarding the wire which goes to the starter relay and starter from my distribution point. Due to the fact the distribution point outlined above is taking the main power from the alternator and because power takes the path of least resistance (the #2 gauged cable), as I understand, running a smaller gauged wire from the distribution point to the starter and starter relay is safe to do? I am leaning towards an 8 gauged wire for simplicity.

Essentially, I would like to keep the wiring clean under the hood and not too "bulky" looking if I can help it, but not at the expense of doing the job safely/properly.

Quick schematic I threw together to illustrate my thought process ... Thank you in advance

I am installing a high amp alternator and as such, I am running a heavy #2 gauged cable from the alternator to an appropriately sized fuse then through the firewall (no bulkhead) to a power distribution point. This distribution point will feed:

1) The batteries which were relocated to the trunk

2) Power to the starter relay

3) Power to the starter

4) New painless wiring harness / main fuse (no ammeter)

5) I am also installing a second separate fuse panel under the dash for the aftermarket electrical items I have installed on the car too. Water pump, fans, fuel pumps, Fitech, water-meth system, stereo etc. This too will be fed from this main distribution point.

I know that my "order" of connections may seem a bit off, but I do believe I have it right overall given the flow of power from the alternator to the batteries. However.. before cutting and going forward, I wanted to clarify I am on the right track regarding the wire which goes to the starter relay and starter from my distribution point. Due to the fact the distribution point outlined above is taking the main power from the alternator and because power takes the path of least resistance (the #2 gauged cable), as I understand, running a smaller gauged wire from the distribution point to the starter and starter relay is safe to do? I am leaning towards an 8 gauged wire for simplicity.

Essentially, I would like to keep the wiring clean under the hood and not too "bulky" looking if I can help it, but not at the expense of doing the job safely/properly.

Quick schematic I threw together to illustrate my thought process ... Thank you in advance