I've got this old thing and I'm brushing off the dust to see if I can get it going. However, I've been searching around for a rebuild kit and I'm coming out without any luck. Does anyone know where I can find a build kit similar to this model? I'm having a tough time locating one. I'm pretty green to this sort of thing so recommendations are appreciated. Mike's Carbs doesn't list this model.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Holley 1920 R-4003B, 4162

- Thread starter zmarty27

- Start date

-

Bugman

Well-Known Member

Bugman

Well-Known Member

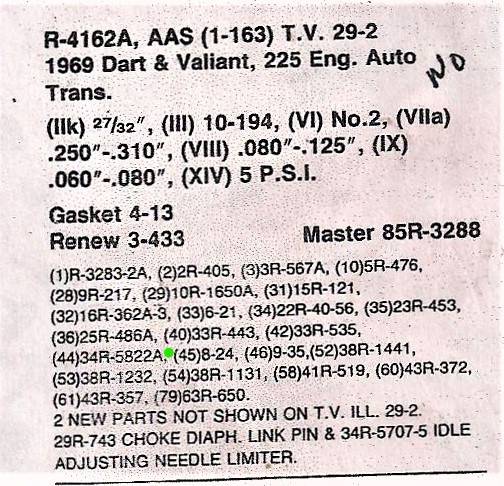

4162 is carb number

Bugman

Well-Known Member

may be wrong one do not know why Holley 1920 Carburetor Rebuild Kit K458

Bugman

Well-Known Member

This shows correct numberhttps://www.carburetor-parts.com/Holley-1920-Carburetor-Rebuild-Kit--K365_p_3249.html

Bugman

Well-Known Member

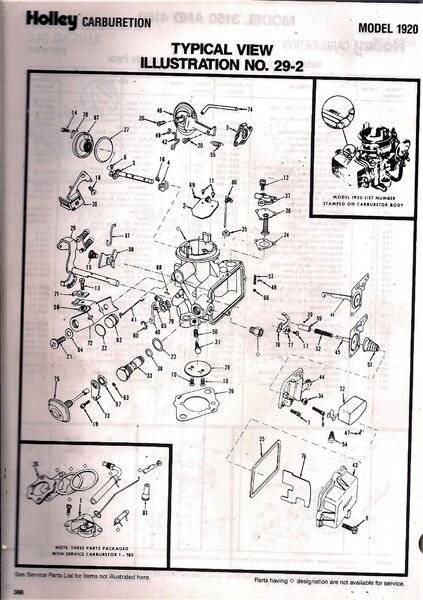

your carb look like this one

Bugman

Well-Known Member

white arrow exhaust heated, air brass fitting, anti ice one year only 1969 for cars? green hole match your manifold may haft to notch gasket.That carb number 4162 shows up in 1969 service manual, down load from mymopar.com

Last edited:

Bugman

Well-Known Member

If your carb does have exhaust heated air see this post Carter BBS Slant 170cui idle problems start at post 58

Bugman

Well-Known Member

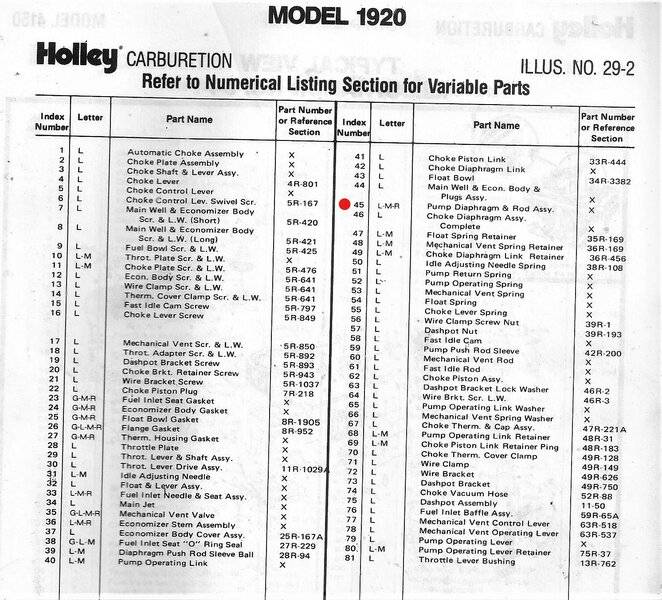

from old holley book

Bugman

Well-Known Member

45 accelerator pump is what good be different

Bugman

Well-Known Member

Walker kit number by application is 15480A, by actual carb number 15460A. Better call mike on this one. He handles walker.

@slantsixdan ......I knew there was an exhaust heated carb base, that would require an intake with drilled passages, no? They would also be the only turquoise ones as well..white arrow exhaust heated, air brass fitting, anti ice one year only 1969 for cars? green hole match your manifold may haft to notch gasket.That carb number 4162 shows up in 1969 service manual, down load from mymopar.com

slantsixdan

=..=

That throttle plate anti-ice system was standard equipment in '69 (only) in the USA; optional equipment in Canada from '60-'68 and standard in '69. Not used in North America after '69. Info on that system is here. Today's gasoline almost all contains d'ethanol, so your throttle plate certainly isn't going to ice up, and the anti-ice system heats up the carburetor something fierce and makes driveability problems.

Best to bypass the metal tube that goes through the exhaust manifold to heat up the air, and install an appropriate hose barb-to-invert-flare brass fitting in the throttle body. Run vacuum hose from the fitting on the underside of the air cleaner directly to that new hose barb. This way you don't screw up the carburetor's idle (which is calibrated with the air coming through that port in mind), and you stop the carb being turned into a teakettle by the unnecessary heat.

Carburetor operation and repair manuals and links to training movies and carb repair/modification threads are posted here for free download.

Best to bypass the metal tube that goes through the exhaust manifold to heat up the air, and install an appropriate hose barb-to-invert-flare brass fitting in the throttle body. Run vacuum hose from the fitting on the underside of the air cleaner directly to that new hose barb. This way you don't screw up the carburetor's idle (which is calibrated with the air coming through that port in mind), and you stop the carb being turned into a teakettle by the unnecessary heat.

Carburetor operation and repair manuals and links to training movies and carb repair/modification threads are posted here for free download.

Charrlie_S

Well-Known Member

Just a FYI. @slantsixdan described this system to me, awhile back, as I had found a NOS exhaust manifold in my stock, and didn't know what the tube through the exhaust runner was for.

You guys are spot on. I hate to have to mod the thing in order to run it on my '74 225, but if that's the way its gotta be, then that's what its gotta be. I may check back in with you guys when I get around to diving deep into it.

Well gang, here is my progress so far. Again, for context, this is a ‘74 225 and I’m trying to strap on this ‘69 Holley 1920. I’m having a bit of tough luck finding the parts to bypass the anti-ice system so any and all recommendations are appreciated. Also, I have a few things left undone because I have to make a quick run to the parts house for hosing. I’ll check in again about the parts for the anti-ice system (these guys around here are on the same skill level as me, it seems and it isn’t something to brag about). Let me know what you think? Thanks!

Last edited:

slantsixdan

=..=

All you need to deal with the remnants of the anti-ice system is a brass fitting with a hose barb on one end and an appropriate male-thread inverted-flare on the other. I don't remember what size thread/flare or hose barb you need; the hose barb is either 3/16" or 1/4"—this will be easy to find out by looking at the nipple on the underside of the air cleaner base plate. A well stocked hardware or plumbing supply store should be able to help you figure out what size flare you need, just going by the thread size in the carburetor base. Then just run rubber hose from the nipple on the underside of the air cleaner base to the hose barb on your new fitting. Done.

Last edited:

Ahh, got the depression source clear now, I was thinking a calibrated orifice to vac. for some reason.....this is just like GM choke heat-assist......maybe not enough as a 1MY & done..All you need to deal with the remnants of the anti-ice system is a brass fitting with a hose barb on one end and an appropriate male-thread inverted-flare on the other. I don't remember what size thread/flare or hose barb you need; the hose barb is either 3/16" or 1/4"—this will be easy to find out by looking at the nipple on the underside of the air cleaner base plate. A well stocked hardware or plumbing supply store should be able to help you figure out what size flare you need, just going by the thread size in the carburetor base. Then just run rubber hose from the nipple on the underside of the air cleaner base to the hose barb on your new fitting. Done.

Rock and roll. Thanks fellas. I plan on modifying the fuel line as well. I found a thread or two by slantsixdan on running up from the pump (with a metal filter and braided line) and directly over to the carb. Excited to clean things up in there.

Also, a quick mention while I’m here… I have a mid sixties (I think) intake without the EGR. However, it doesn’t have a bolt to fit my A/C bracket on and it is honestly something I didn’t think of before purchasing. Now it’s all clean and painted ready for application. Referring to pic number 1 in my series posted, you can see where the bracket mounts below the carb and above the EGR. Could I tap into the old intake for a mounting bolt? Or is that bad mojo? If you need a pic of what I have, I can post tomorrow for reference. Thanks again, guys.

slantsixdan

=..=

Yep, that's kosher.

Here is the passenger side for reference. The port to the left, I assume would run to the distributor (which is the exposed line with clamp to the far left). The port to the right with the brass fitting is the anti ice, which I know to run to my air cleaner. This would leave my vacuum amplifier, charcoal canister (if the opposing port is not the correct placement), and pcv valve unaccounted for. Any advice? My manual is exclusively partial to the 1945.

Bugman

Well-Known Member

Will I run the charcoal canister line to this port? No goes to pvc valve

-